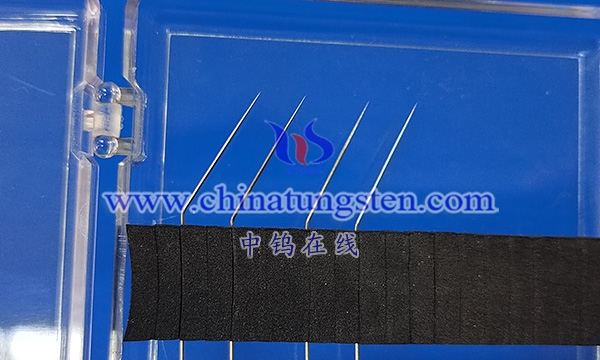

Sharpened tungsten needles are needle-shaped tools made of tungsten steel. They have the characteristics of high hardness, high wear resistance, corrosion resistance, high temperature performance, etc., and are widely used in various fields. When packing sharpened tungsten needles, the following factors need to be considered:

1. Safety: Sharpened tungsten needles are relatively sharp tools that can easily cause harm to the human body. Therefore, measures need to be taken to ensure safety during the packaging process. First of all, appropriate packaging materials should be selected, such as cardboard boxes, wooden boxes, etc., to ensure the firmness and stability of the packaging. Secondly, during the packaging process, the sharpened tungsten needles should be avoided from protruding or being exposed to the outside to avoid causing harm to the human body.

2. Moisture resistance: Sharpened tungsten needles are usually used for operations in various environments, so measures need to be taken to ensure their moisture resistance. During the packaging process, you can choose packaging boxes made of moisture-proof materials, such as plastic boxes, metal boxes, etc., to prevent the sharpened tungsten needles from getting damp, rusting or deteriorating. At the same time, during storage, you should also pay attention to keeping dry and ventilated to prevent the sharpened tungsten needles from getting damp.

3. Portability: Sharpened tungsten needles usually need to be carried or transported to different locations for use, so the portability of the packaging needs to be considered. During the packaging process, you can choose a lightweight and compact packaging box for easy carrying and transportation. At the same time, you can also add a protective layer to the outside of the packaging box, such as foam pads, bubble bags, etc., to avoid the impact or vibration during transportation.

4. Identification: The packaging box of the sharpened tungsten needle should be affixed with a corresponding logo for easy distinction and identification. The logo should include information such as product name, specifications, production date, instructions for use, etc. At the same time, personalized logos can also be customized according to customer requirements to improve product recognition and brand image.

Based on the above factors, the following are specific steps and suggestions for packaging sharpened tungsten needles:

1. Choose appropriate packaging materials: Choose appropriate packaging materials according to product characteristics and customer requirements. Commonly used packaging materials include cardboard boxes, wooden boxes, plastic boxes, metal boxes, etc. Choosing appropriate packaging materials can ensure the safety and moisture resistance of the product.

2. Design a reasonable packaging structure: Design a reasonable packaging structure to ensure the stability and portability of the product. In the design of packaging structure, the size and shape of the product, as well as the design of the lining and protective layer should be taken into account. At the same time, it should be ensured that the box is easy to open and close for easy use and storage.

3. Adding logos and instructions: Adding logos and instructions on the box can facilitate customers to use and understand the product. The logo should include information such as product name, specifications, production date, instructions for use, etc. At the same time, personalized logos can also be customized according to customer requirements to improve product recognition and brand image.

4. Lining and protection: Adding appropriate lining and protective layers to the inner packaging can prevent the product from being affected by impact or vibration during transportation. Commonly used linings and protective layers include foam pads, bubble bags, paper, etc. At the same time, special linings and protective layers can also be designed according to the shape and characteristics of the product.

5. Sealing the box: After completing the lining and protection, the box should be sealed to ensure the safety and moisture resistance of the product. Commonly used sealing methods include adhesives, sealing tapes, etc. At the same time, attention should also be paid to the tightness and uniformity of the seal to avoid gaps or looseness.

6. Storage and transportation: After packaging, the product should be stored and transported to the designated location. During storage and transportation, care should be taken to maintain a dry, ventilated and light-proof environment to prevent the product from getting damp or deteriorating. At the same time, care should be taken to avoid excessive stacking or squeezing to avoid damage to the product.

In short, reasonable packaging of sharpened tungsten needles needs to consider factors such as safety, moisture resistance, portability, identification and protection. By selecting appropriate packaging materials and structural designs, adding logos and instructions, lining and protecting, and sealing packaging boxes, the quality and brand image of the product can be improved, providing customers with better user experience and services.

More details of tungsten needles, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595