The manufacturing process of tungsten copper probe can be divided into the following steps:

1. Batching: Select appropriate tungsten copper alloy materials according to needs and batch them according to a certain proportion.

2. Melting: Put the ingredients into a high-temperature melting furnace and melt them at high temperature to form a tungsten copper alloy.

3. Casting: Pour the smelted tungsten copper alloy into a mold and form a casting after cooling.

4. Heat treatment: Heat treatment is performed on the casting to eliminate stress, improve strength and stability.

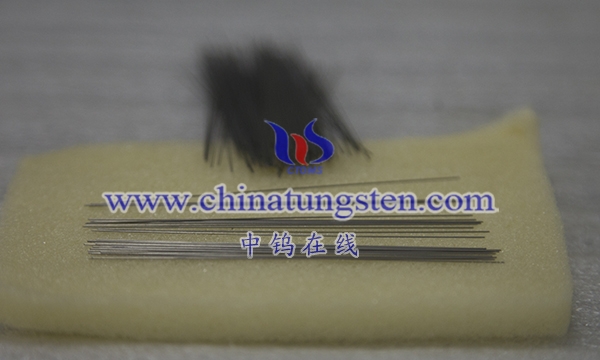

5. Machining: Machining is performed on the casting, such as turning, milling, drilling, etc., to obtain a probe of the required shape and size.

6. Surface treatment: Polishing, gold plating, etc. are performed on the probe surface to improve conductivity and corrosion resistance.

7. Detection: The probe is inspected to ensure that it meets the design requirements and quality standards.

The manufacturing process of tungsten copper probe requires strict quality control and environmental control to ensure the accuracy and stability of the probe. At the same time, safety issues need to be paid attention to during the manufacturing process, such as wearing protective clothing and avoiding the use of hazardous chemicals.

More details of tungsten needles, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595