The benefits of nanonization of negative electrode materials are:

(1) The electrochemical performance can be improved. It reduces the migration path of lithium ions, helps maximize the reaction of lithium ions, and improves the cycleability of materials; (2) The large specific surface area and small size of nanomaterials contribute to the excellent reversible cycle capacity of lithium-ion batteries; (3) Controlling the reaction time and the morphology of nano-products can effectively improve the electrochemical performance of the reversible capacity. Lithium battery anode materials are roughly divided into the following categories:

1.Carbon Anode Material

Most of the anode materials actually used in lithium-ion batteries are carbon materials. At present, commercial lithium-ion batteries mainly use graphite as the anode material. The theoretical specific capacity of graphite is 372 mA·h/g, while the high-end graphite on the market Materials can reach 360-365 mA·h/g, so the space for improving the energy density of the corresponding lithium-ion battery is quite limited, and it is increasingly unable to meet the needs of the next generation of high-capacity and high-power batteries.

2.Nano-Silicon Anode Material

Nano-silicon is also one of the research directions. The theoretical specific capacity of Si material reaches 3572mAh/g, which is much higher than that of graphite material, so it has attracted extensive attention. However, Si will produce a volume expansion of up to 300% during the process of lithium intercalation and delithiation. , resulting in particle breakage and active material falling off, in order to overcome this shortcoming, Si materials are made into nanoparticles to relieve the mechanical stress caused by the expansion of Si particles. At present, other Si nanostructures include 1D nanowires, which can form good contact with the current collector and electrolyte, and leave enough space for Si expansion, so the reversible specific capacity of this material is as high as 2000mAh/ g, and has good cycle performance.

Silicon has a large specific capacity, but it is prone to huge deformation during charging and discharging, which leads to the failure of the level sheet, so the general research direction now is silicon composite materials.

At present, the common silicon-carbon anode materials mainly include carbon-coated nano-silicon and silicon nanowires.

3.Nano Oxide Material

Including nano titanium dioxide, nano tungsten oxide, nano iron oxide, etc.

Nano-iron oxide FE2O3 has the following characteristics as the negative electrode material of lithium-ion batteries:

- High capacity. The theoretical capacity of iron oxide is 1007mAh/g

- Good security. Due to the high discharge voltage of iron oxide, it can prevent the growth of lithium dendrites and thus avoid the dendrite growth caused by discharge, resulting in a short circuit inside the battery.

- Abundant resources, low price, environment-friendly, non-toxic and harmless.

4.Tin-Based Anode Material

Tin-based negative electrode materials can be divided into two types: tin oxides and tin-based composite oxides.

The theoretical capacity of tin oxide is 875mAh/g, and nano-tin oxide, as the anode material of lithium-ion batteries, has the characteristics of high capacity and excellent price.

5.Alloy Anode Material:

Including tin-based alloys, silicon-based alloys, germanium-based alloys, aluminum-based alloys, antimony-based alloys, magnesium-based alloys and other alloys.

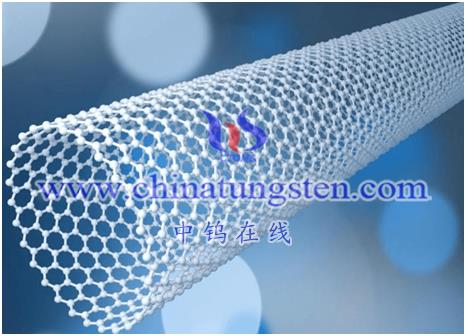

6.Nano Carbon Material

At present, more studies are made on the composite material composed of nano-iron oxide and graphite, which is of great significance when applied to the negative electrode of the electrode. Nano-titanium dioxide (anatase/rutile) has excellent high rate performance and cycle stability, fast charge and discharge performance and high capacity, good reversibility of lithium deintercalation, can effectively reduce the capacity decay of lithium batteries, and increase the stability of lithium batteries and improve electrochemical performance. Improve the first discharge specific capacity of battery materials.

More details of tungsten oxide product, please visit website: tungsten-oxide.com

Please contact CHINATUNGSTEN for inquiry and order of tungsten oxide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595