Customers usually have high quality requirements for tungsten wire for textiles weaving gloves, especially when it comes to high performance, precision manufacturing and specific application areas. The following are the main quality requirements of customers for tungsten wire for textiles weaving gloves:

- Purity and composition

Requirement: The chemical purity of tungsten wire usually needs to reach more than 99.95% to ensure the stability of material performance.

Reason: High-purity tungsten wire can maintain its performance under high temperature and corrosive environment, and will not cause performance degradation due to impurities. ’

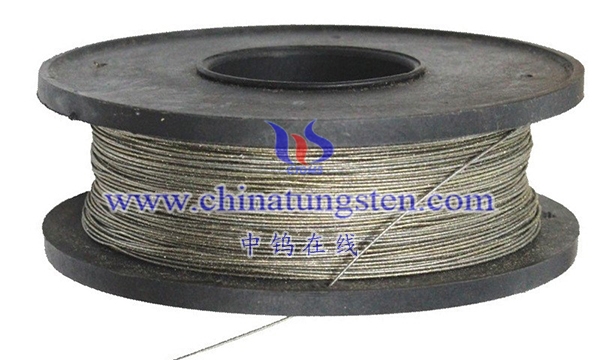

- Diameter accuracy

Requirement: The diameter of tungsten wire needs to be within a strict tolerance range, usually ±0.001 mm or less.

Reason: Diameter consistency is critical to braiding accuracy, material strength and performance of the final product.

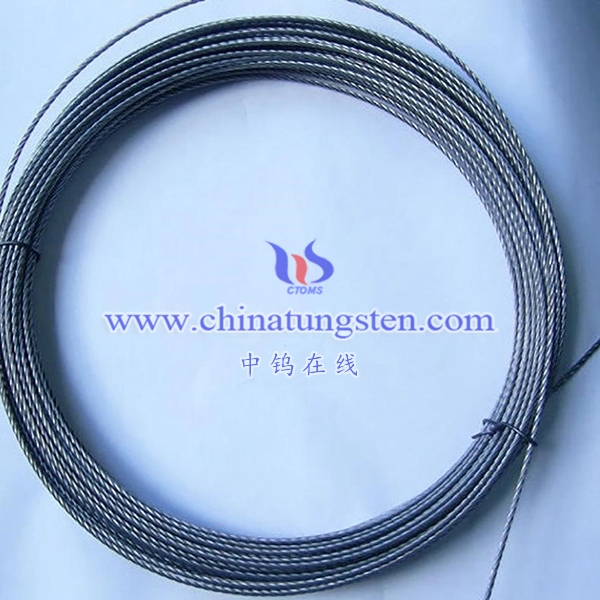

- Surface finish

Requirement: The surface must be smooth and flawless, without cracks, scratches, oxide scale or other surface defects.

Reason: Surface finish directly affects the braiding performance of tungsten wire and the appearance and durability of the final product.

- Mechanical properties

Requirements: include high tensile strength, high fracture toughness and appropriate ductility. Customers usually require a tensile strength greater than 2000 MPa and sufficient flexibility.

Reason: These properties determine the durability of the tungsten wire during the weaving process and the durability of the final product, especially in high temperature or high stress environments.

- High temperature resistance

Requirements: Tungsten wire needs to maintain its mechanical strength and physical properties at high temperatures, and the melting point should be over 3400°C.

Reason: In high temperature applications, such as aerospace or electrothermal equipment, tungsten wire needs to maintain its structural and functional integrity.

- Electrical conductivity

Requirements: Good electrical conductivity, usually requiring stable electrical conductivity at high temperatures.

Reason: In electrical and electronic applications, the conductivity of tungsten wire directly affects the efficiency and reliability of the equipment.

- Corrosion resistance

Requirements: Tungsten wire needs to maintain stability in corrosive environments and will not easily oxidize or corrode.

Reason: Many tungsten wires are used in harsh environments such as chemicals and energy, so corrosion resistance is a key quality indicator.

- Uniformity

Requirement: Tungsten wire should have consistent chemical composition, structure and properties throughout its length, and should not have obvious local weaknesses or defects.

Reason: Uniformity ensures consistency and reliability during weaving and application.

- Toughness and fatigue resistance

Requirement: Tungsten wire must maintain good toughness and fatigue resistance during repeated bending or high-frequency use.

Reason: For applications that require repeated bending or work in a vibrating environment, the fatigue resistance of tungsten wire is very important.

- Wear resistance

Requirement: High wear resistance to ensure long-term use without loss in a friction or contact environment.

Reason: During the weaving process or in use, the wear resistance of tungsten wire affects its life and performance.

- Oxidation resistance

Requirement: Tungsten wire should maintain its physical and chemical stability when exposed to air or an oxidizing environment.

Reason: Oxidation resistance extends the service life of tungsten wire in high temperature or high stress environments.

- Consistency and traceability

Requirement: Each batch of tungsten wire must be consistent in quality, and detailed quality inspection records and traceability must be available.

Reason: Customers need to ensure that the performance of tungsten wire is stable between batches, and traceable records help quality management and problem tracking.

More details of tungsten wires, please visit website: http://tungsten.com.cn/tungsten-wires.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595