- Nano tungsten oxide – tungsten yellow (VK-WO3, 50nm)

Tungsten trioxide, yellow powder. Insoluble in water, soluble in alkali, slightly soluble in acid. It is used for making high melting point alloy and cemented carbide, tungsten wire and fireproof material. It can be obtained by co-melting tungsten ore with soda ash and then adding acid.

Tungsten trioxide is light yellow rhombohedral crystal system crystalline powder. The color changes from light to dark when heated. The specific gravity is 7.16 g/cm3, the melting point is 1473℃, the boiling point is 1750℃, it sublimates significantly at 850℃, and it is green when melting. Stable in air, insoluble in water and inorganic acids except hydrofluoric acid, can slowly dissolve in ammonia and concentrated hot sodium hydroxide solution. Tungsten trioxide is easily reduced by various reducing agents. At room temperature, even a small amount of organic matter can reduce it and change its color. But when heated in the air, it returns to its original color. At 700~900℃, tungsten trioxide is easily reduced to tungsten metal by hydrogen, carbon monoxide and carbon.

Main applications:

- Part of yellow tungsten oxide is used in the production of chemical products, such as paints and coatings, catalysts for the petroleum industry, etc.; however, the oxide is an intermediate product, and part of it is used in the production of metallic tungsten powder and tungsten carbide powder, which in turn is used in the production of metallic tungsten products and is used in a large number of applications with the production of tungsten alloy products, such as tungsten copper, tungsten nickel, tungsten nickel-iron, tungsten silver, tungsten rhenium, tungsten thorium and so on.

- Yellow tungsten oxide is used for many purposes in daily life. Such as industrial X-ray screen phosphor production of fireproof fabrics and gas sensors, tungstate.

- Due to its rich yellow color, tungsten oxide is also used as a pigment in ceramics and paints.

- Currently, nano yellow tungsten oxide (VK-WO3 50nm) is used more in lithium battery anode materials and in new energy vehicles.

Nano yellow tungsten oxide (VK-WO3 50nm) for lithium battery anode

In the field of energy storage research, tungsten oxide has become the focus of research in recent years due to its advantages of good chemical stability, high chemical activity, large theoretical specific capacity, and strong electrical conductivity. Tungsten oxide is a defective state material, and the oxygen holes on the surface can become electron-donating bodies in the conduction band, thus making the material an n-type semiconductor. Therefore, in practical applications, the adsorption capacity of tungsten oxide nanomaterials can be significantly improved by increasing their specific surface area and surface defects.

Currently, researchers have prepared many kinds of crystalline structures of tungsten oxide nanomaterials, such as hollow nanospheres, sea urchin-like nanoparticles, nanowires, mesoporous nanomaterials, etc., all of which have large specific surface area or surface defects, and can enhance the physicochemical adsorption performance of lithium battery anode materials.

Second, nanometer tungsten oxide–Violet tungsten (VK-WO2.7, 80-100nm)

The phase composition of tungsten oxide is WO2.72 (or W18O49). Due to its unique crystal structure, tungsten oxide is used to produce fine tungsten powder and fine tungsten carbide powder with superior performance, and it is soon applied in production.

Wolfram is a different form of tungsten oxide, which has a unique crystal structure with other tungsten oxides (wolfram), and its performance is also very different. The large particles of wolfram are all with sharp angles, aggregated by a small cube, the surface are broken to different degrees, and covered with cracks; the morphology of wolfram is significantly different from the other three, each large particle is a loose cluster of particles composed of needle-like or rod-like grains. All tungsten oxide clusters.

All tungsten oxide grains are rich in internal cracks, and among them, tungsten oxide grains are not only rich in cracks, but also have needle-like or rod-like grains. This structure of tungsten oxide particles has a lot of voids, which makes its bulk density lower, and is conducive to the infiltration of hydrogen and the escape of water vapor during the reduction process, so that the reduction not only begins on the surface, but also in the interior at the same time. The particle morphology of wolfram is rod-like, while the rest of tungsten oxide particles are nearly spherical; the particle size of wolfram is larger than that of tungsten oxide particles.

The phase composition of wolfram is WO2.72 ( or W18 O49 ), tungsten violet (TVO) powder has large mesopore volume, small microporous volume, narrow pore size distribution, small fractional dimension and large average pore size, which is favorable for hydrogen reduction to produce ultrafine tungsten powder and unfavorable for doping process, and it is a kind of unique crystal structure, so it is used to produce fine tungsten powder and fine tungsten carbide powder.

Main applications:

Purple tungsten oxide (VTO) is also known as tungsten violet oxide (TVO). Purple tungsten oxide is produced in the process of calcining ammonia metatungstate, and different producers produce purple tungsten oxide with different contents. It is not a compound in the chemical sense, but is composed of different components such as arsenic trioxide, copper tungsten, and low levels of tungsten trioxide. The relative content of these compounds in purple tungsten oxide depends on the calcination parameters.

Purple tungsten oxide is a finely ground purple powdery crystal. It is produced during the production of ammonium paratungstate in reduced form at accurately controlled temperatures. Xiamen Chinatungsten Online Technology Co., Ltd. produces two kinds of purple tungsten oxide with standard oxygen content. Purple tungsten oxide is mainly used to produce tungsten metal powder and tungsten carbide. Purple tungsten oxide can also be used to manufacture ultra-fine tungsten powder and nano tungsten powder.

Nano tungsten oxide – purple tungsten used in lithium batteries (VK-WO27 , 80-100nm)

Nano tungsten violet oxide is not only a multifunctional inorganic oxide material, but also one of the materials with excellent lithium storage performance, which has large application value in the field of lithium battery cell.

Compared with ordinary batteries, lithium batteries containing ultrafine particles of purple tungsten oxide have the following advantages:

- higher energy-to-weight ratio;

- higher safety coefficient

- long cycle life

- good charging and discharging multiplier performance;

- good high and low temperature resistance.

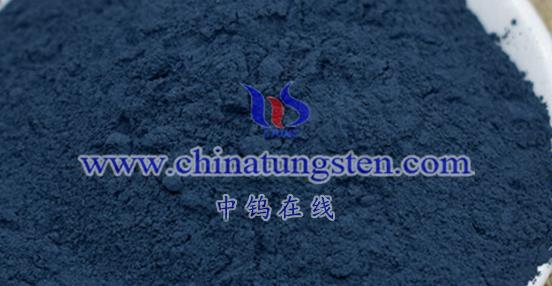

III. Nano tungsten oxide–Bluetungsten (VK-WO29 , 80-100nm)

Bluetungsten refers to a class of dark blue compounds containing tungsten(VI) and tungsten(V) in mixed valence. It is generally formed in solution. Pure tungsten compounds are produced from ammonium paratungstate, tungsten trioxide and sodium tungstate solution.

Bluish tungsten refers to a class of dark blue compounds containing a mixture of tungsten(VI) and tungsten(V) valence states. It is generally formed in solution. A suspension of tungsten oxide in hydrochloric acid is reduced by zinc metal to obtain tungsten blue.

In addition, moist tungsten oxide produces a blue color by ultraviolet light and white colloidal tungstic acid in indirect sunlight.

How to prepare wolfram blue?

The preparation of wolfram is a method of producing pure tungsten compounds by using ammonium paratungstate, tungsten trioxide and sodium tungstate solution as raw materials. Industrially speaking, wolfram is a mixture of WO2.72, WO2.90, W20O58 and (NH4)х-WO3. The latter is ammonium tungsten bronze (ATB), which is a non-stoichiometric compound. With ATB as the main phase and WO2.90 as the main phase of wolfram is an excellent raw material for the production of tungsten, wolfram is also an excellent raw material for tungsten-based cemented carbide and other tungsten products.

There are two types of production methods of wolfram: fire method and wet method.

Fire method

Fire method is a common method in industry. Generally, ammonium paratungstate (APT) is used as raw material, and it is produced by thermal decomposition or mild reduction with hydrogen. It can also be produced by mild reduction of WO3 with hydrogen, but the quality is not as good as that of APT as raw material.

Industrial production of doped wolfram is usually in four-tube or eleven-tube electric furnace with hydrogen mild reduction of APT and get. The chemical composition of wolfram is WO2.88~WO2.92, containing NH3 0.3%~0.8%.

Wet method

Wet method is a new method developed by research. With hydrogen reduced ammonium tungstate solution can be produced composition of 3.5 (NH4)2O-5WO2-13WO3-4.5H2O bluetungsten. The organic phase of tungsten can also be produced by using hydrogen reduced tungsten solvent Senlution tungsten O: W = 2.82 blue tungsten. Internal reduction method can produce wolfram with WO2.90 as the main phase.

Main applications:

- materials for gas sensors

- solar photographic film

- Pigment

- Catalysts

- X-ray shielding and fireproof fabrics

More details of tungsten oxide product, please visit website: tungsten-oxide.com

Please contact CHINATUNGSTEN for inquiry and order of tungsten oxide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595