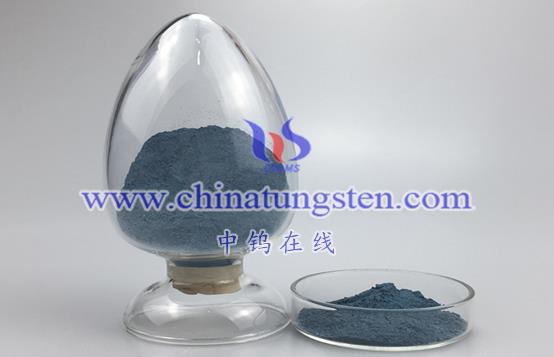

Definition: The bulk density of tungsten oxide refers to the mass of tungsten oxide powder per unit volume in its natural, loose-packed state. It is an important physical property that reflects the degree of packing and void space between the particles.

Factors Affecting Bulk Density: Several factors influence the bulk density of tungsten oxide powder:

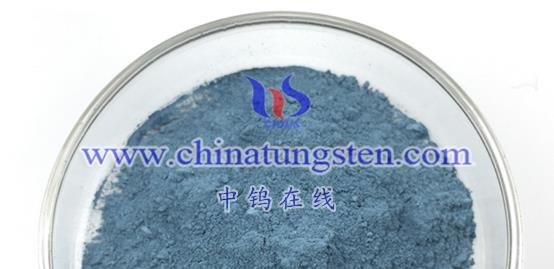

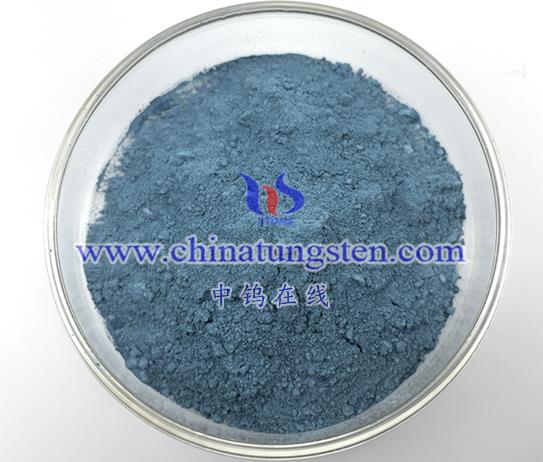

- Particle Shape: Regularly shaped particles generally have a higher bulk density because they pack together more tightly, leaving less void space.

- Particle Size: Uniform particle size can lead to a higher bulk density as the particles fit together more efficiently.

- Surface Roughness: Smoother particles tend to pack more closely, leading to a higher bulk density.

- Particle Interaction: The forces between particles, such as electrostatic or van der Waals forces, can also affect how tightly the particles pack together.

Influences from Production and Properties:

- Production Process: Variations in grinding time, grinding media, and other processing parameters can result in different particle sizes and shapes, thus affecting the bulk density.

- Purity and Crystal Structure: The purity of the tungsten oxide and its crystalline form (e.g., WO3, WO2) can also impact its bulk density.

Significance in Applications: Bulk density is crucial in various applications involving tungsten oxide powder, including:

- Coatings and Thin Films: The bulk density affects how the powder disperses and adheres to surfaces, influencing the quality and performance of coatings and films.

- Catalysts: For catalysts, the bulk density affects the packing of the catalyst material, which in turn impacts the catalytic efficiency and reaction rates.

- Powder Handling: Bulk density affects the flowability and handling of powders, which is important for processes such as mixing, transport, and packing.

In summary, understanding the bulk density of tungsten oxide is essential for optimizing its performance in different applications. It helps ensure proper dispersion, flow, and packing of the powder, which directly influences the final product’s characteristics and effectiveness.

More details of tungsten oxide product, please visit website: tungsten-oxide.com

Please contact CHINATUNGSTEN for inquiry and order of tungsten oxide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595