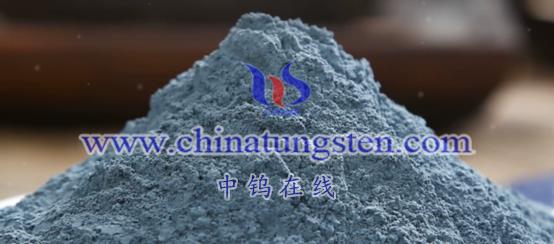

Concept of Tungsten Bronze Compounds

Tungsten bronze (TB) is a typical non-stoichiometric compound, usually exhibiting a cubic or tetragonal crystal structure. It is insoluble in water and all acids except for hydrofluoric acid, but it is soluble in alkaline reagents. The general chemical formula of tungsten bronze can be written as MxWO3 (where x = 0 to 1), with common M elements being those from the first and second main groups, as well as rare earth elements. The variation in the M species and the value of x can impart either conductive or semiconductive properties to the compound. Crystallographic research shows that tungsten bronze is essentially a solid solution formed when alkali metal atoms are inserted into the WO3 lattice. When all the vacancies are filled, the resulting compound is MWO3. The formation of tungsten bronze is related to the variable oxidation states of tungsten. If only part of the vacancies is replaced by alkali metal atoms, some tungsten atoms will change from a +6 oxidation state to a +5 oxidation state.

Classification of Tungsten Bronze Compounds

Tungsten bronze compounds have a unique tunnel structure and are generally classified based on their crystal structure, such as perovskite-type tungsten bronze (PTB), tetragonal tungsten bronze (TTB), hexagonal tungsten bronze (HTB), and intergrowth tungsten bronze (ITB). Because perovskite-type and hexagonal tungsten bronzes are often non-stoichiometric compounds, they can be grouped together as non-stoichiometric compounds. In tungsten bronzes, tungsten exists in mixed oxidation states of W6+, W5+, and W4+, which balances the overall charge of the compound. The tunnel structure and these special oxidation states give tungsten bronze excellent properties, such as electron and ion conductivity, superconductivity, and optical properties. As a result, tungsten bronze has attracted extensive research interest for its potential applications in secondary batteries, electrochromic devices, and chemical sensors.

- Non-Stoichiometric Tungsten Bronze

Perovskite-type tungsten bronze (PTB) and hexagonal tungsten bronze (HTB) are special non-stoichiometric tungsten bronze compounds, with the general formula MxWO3 (0 < x < 1), where M is typically an alkali metal like K or Na, but can also be alkaline earth metals such as Ca, Sr, Ba, as well as rare earth elements and Cu, Ag, H, etc.

These compounds feature vibrant colors, metallic luster, high conductivity, and rapid ion transport properties, with conductivity reaching up to 2.5 × 10^6 S/m, and they also exhibit low-temperature superconductivity.

- Intergrowth Tungsten Bronze (ITB)

Intergrowth tungsten bronze (ITB) is a stoichiometric tungsten bronze compound, generally containing B2O62- anions, and is formed due to oxygen deficiency or the presence of additional B ions or BO groups occupying the largest interstitial sites. It is typically expressed as (AO)m.(B2O5)n or (AO)m.(BO3)n, and is referred to as intergrowth tungsten bronze. Examples include BaO.(Nb2O5)2, BaO.(Ta2O5)2, Nb8W9O47. Recent studies have shown that MxWO3 (M = K, Rb, Cs, x = 0.19–0.33) forms hexagonal tungsten bronze (HTB). However, as x decreases (x < 0.10), hexagonal tungsten bronze becomes unstable and forms intergrowth tungsten bronze, where WO3 layers alternate with hexagonal tungsten bronze, and this structure is now known as quasi-two-dimensional tungsten bronze.

- Tetragonal Tungsten Bronze

Tetragonal tungsten bronze (TTB) is the most common, widely used, and most studied structure. Many orthogonal tungsten bronze structures are superstructures of TTB, so they are usually categorized under TTB. Hence, when referring to tungsten bronze structures, TTB is generally implied.

Methods for Preparing Tungsten Bronze Compounds

- Wet Chemical Method

This method was first applied in the preparation of HxWO3. The typical process involves immersing WO3 crystals in an acidic solution with metallic powders (such as Zn, Pb, Sn, etc.) and reacting in a special container (like a Jones reactor) that isolates the reactants from the air to prepare hydrogen tungsten bronze. During the reaction, hydrogen enters the regular vacancies in WO3.

For example, hexagonal WO3 and hydrochloric acid with Zn can be used to prepare hexagonal H0.3WO3, which has metallic-like conductivity. WO3 in 1 mol/L sulfuric acid with In as a catalyst can be used to prepare tetragonal H0.23WO3.

Wolframite compounds like ammonium tungstate ((NH4)10(W12O41)·5H2O) can be heated in a non-aqueous solution (such as glacial acetic acid, ethylene glycol, or a mixture of both) under pressure at 200°C to produce hexagonal (NH4)xWO3.

Wet chemical methods are popular due to their lower synthesis temperatures and good crystallization, but the types of tungsten bronze compounds produced by this method are still limited.

- Thermal Reduction Method

2.1 Phase-Phase Thermal Reduction Method

This early method for preparing tungsten bronze involves mixing WO3, tungsten powder (or WO2), and metal M tungsten salts in appropriate proportions, then heating them under inert gas or vacuum. The reaction temperature is generally around 1000°C. After the reaction, unreacted impurities are removed to obtain relatively pure MxWO3. The reaction can be represented as:

x/2 M2WO4 + (1-x) WO3 + x/2 WO2 → MxWO3

2.2 Thermal Decomposition Method

In this method, tungsten bronzes are prepared by the thermal decomposition of precursor compounds, such as polyacid complexes or peroxide polyacid compounds. One example is the thermal decomposition of ammonium tungstate (APT) to prepare hydrogen tungsten bronze:

- (NH4)10(H2W12O42)·7H2O decomposes at 100–200°C into (NH4)10(W12O41)·5H2O

- (NH4)10(W12O41)·5H2O decomposes at 200–250°C into (NH4)0.33WO3

- At 250–575°C, (NH4)0.33WO3 becomes relatively stable, and converts into H0.33WO3 and WO3.

Ammonium tungstate can decompose to form HxWO3, with the temperature range generally between 150–350°C. The process is often accompanied by crystal form changes, as represented by the equation:

(NH4)xWO3 → HxWO3 + xNH3(g)

- Electrochemical Method

Electrochemical methods are commonly used to prepare tungsten bronzes, especially hydrogen tungsten bronze and lithium tungsten bronze. This method does not require high temperatures and can yield well-formed crystals.

The electrochemical process typically involves making a WO3 electrode and using it as the cathode, with an inert anode like graphite or Pt, or a lithium foil anode. Electrolysis is conducted in sulfuric acid, nitric acid, or corresponding lithium salts, producing hydrogen tungsten bronze and lithium tungsten bronze. The corresponding cathode reaction is:

xH+ + WO3 + xe = HxWO3

xLi+ + WO3 + xe = LixWO3

Properties and Applications of Tungsten Bronze Compounds

Tungsten bronzes have excellent electronic and ionic conductivity, superconductivity, and optical properties, making them promising for various applications. The study of their superconductivity and conductivity began in the 1960s and 1970s. While there are still reports on their conductivity types and electron conduction mechanisms, conductivity and superconductivity are no longer the main research focus.

Under certain conditions, compensating ions embedded into WO3 form tungsten bronze, and their absorption and scattering of light give the material its color. The intensity of absorption and scattering changes with the value of x, resulting in tungsten bronze exhibiting different colors. H+, Li+, Na+, and Ag+ ions are particularly notable for their optical properties. Among these, HxWO3 absorbs light most strongly, followed by Li+ tungsten bronze. Both lithium and sodium tungsten bronzes reach their maximum light absorption at x ≈ 0.6, while hydrogen tungsten bronze does not show a maximum.

Electrochromic and photochromic devices, which are important applications of tungsten bronze, rely on its optical properties. The electrochromic effect is also related to the reversible electrochemical insertion of ions like H+ and Li+ into WO3 electrodes. Photochromic embedding involves ions such as H+, Li+, and Na+ reversibly entering WO3 under light irradiation, an important property for applications like photochromic color change and photoelectric conversion. Tungsten bronze also has promising applications in humidity sensors, chemical sensors, and other devices due to its sensitivity to moisture and certain chemicals.

More details of tungsten oxide product, please visit website: tungsten-oxide.com

Please contact CHINATUNGSTEN for inquiry and order of tungsten oxide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595