There are significant differences between cut-resistant tungsten wire and titanium wire in many aspects. The following is a detailed analysis of the main differences between the two materials:

- Material properties and composition

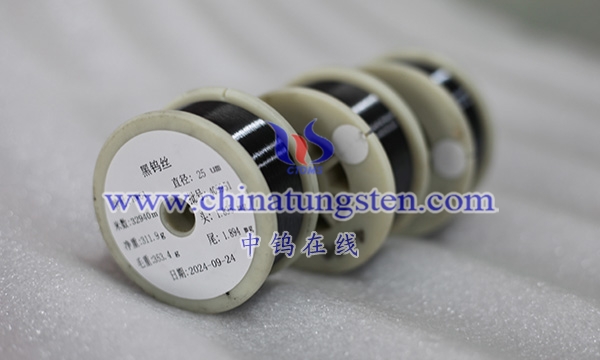

Cut-resistant tungsten wire: mainly made of high-purity tungsten metal. Tungsten is a metal with a high melting point (3410℃) and high hardness, which makes the cut-resistant tungsten wire have extremely high wear resistance and cutting resistance.

Titanium wire: made of titanium metal or titanium alloy. Titanium is a lightweight (density is about 4.5g/cm³), high-strength metal, and has good corrosion resistance and biocompatibility.

- Physical properties

- Corrosion resistance

Cut-resistant tungsten wire: It has good chemical stability and can maintain its performance in a variety of environments, but it may be affected under certain specific conditions (such as oxidizing environments).

Titanium wire: It has excellent corrosion resistance, especially excellent resistance to corrosion by seawater, chlorine and various acids. This makes titanium wire have broad application prospects in marine engineering and chemical industry.

- Application fields

Cut-resistant tungsten wire: Due to its high hardness, high wear resistance and high melting point, cut-resistant tungsten wire is widely used in photovoltaic silicon cutting, metal processing and other occasions that require high strength and high precision cutting.

Titanium wire: Titanium wire is widely used in aerospace, medical, chemical and other fields due to its light weight, high strength, corrosion resistance and biocompatibility. For example, in the aerospace field, titanium wire is used to manufacture key components of aircraft and rockets; in the medical field, titanium wire is often used to manufacture implants such as artificial joints and dental implants.

- Price and cost

Generally speaking, due to the rarity and high purity requirements of tungsten, the price of cut-resistant tungsten wire is relatively high. The price of titanium wire is affected by many factors, including raw material prices, processing technology, etc.

More details of tungsten wires, please visit website: http://tungsten.com.cn/tungsten-wires.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595