Although cut-resistant tungsten wire has high corrosion resistance and chemical stability, it does not mean that it can be exposed to strong acid environment without limit.

First of all, tungsten metal itself is an element with relatively stable chemical properties and is not easy to react chemically with most substances. However, the strong acid environment is extremely corrosive and can dissolve or destroy many metals and non-metallic materials. For tungsten wire, although its corrosion resistance is good, it may still be corroded to a certain extent under extreme conditions (such as extremely high concentrations of strong acid, long-term immersion, etc.).

Secondly, the surface of cut-resistant tungsten wire is usually specially treated to improve its cutting performance and corrosion resistance. However, these treatment layers may be damaged in a strong acid environment, causing the tungsten wire matrix to be directly exposed to strong acid, thereby accelerating the corrosion process.

In addition, it is also necessary to consider that even if the tungsten wire is not immediately corroded and damaged in a strong acid environment, a layer of oxides or other compounds may form on its surface. These compounds may affect the cutting performance and surface quality of the tungsten wire, thereby affecting its effect in practical applications.

In practical applications, appropriate materials should be selected according to the specific working environment and requirements, and relevant operating procedures and safety specifications should be followed to ensure the normal operation of the equipment and the safety of personnel.

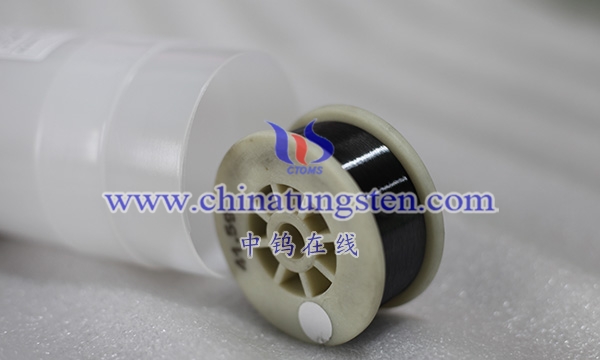

More details of tungsten wires, please visit website: http://tungsten.com.cn/tungsten-wires.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595