The fracture toughness of cut-resistant tungsten wire is an important performance indicator, which indicates the ability of the material to resist crack propagation when subjected to external force. Regarding the fracture toughness of cut-resistant tungsten wire, it can be analyzed from the following aspects:

- Definition and importance of fracture toughness

Fracture toughness is an important indicator to measure the toughness of materials, which is directly related to the safety and reliability of materials during use. For cut-resistant tungsten wire, high fracture toughness means that it can better resist the generation and expansion of cracks when subjected to cutting force or other external forces, thereby improving its service life and stability.

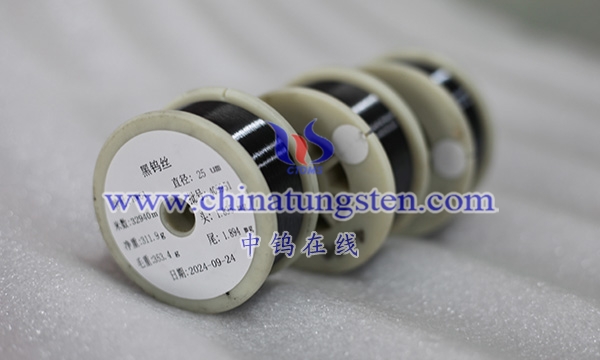

- Fracture toughness performance of cut-resistant tungsten wire

According to publicly released information, there are certain requirements for the fracture toughness of cut-resistant tungsten wire under specific specifications. For example, in the performance requirements of cut-resistant tungsten wire for photovoltaics, tungsten wires of different specifications clearly specify the minimum value of their fracture toughness (such as 9MPa·m1/2 or higher). This shows that the importance of fracture toughness has been fully considered in the design and production of cut-resistant tungsten wire, and it has been guaranteed by technical means.

- Factors affecting the fracture toughness of tungsten wire with cut resistance

Material purity and composition: High-purity tungsten metal and reasonable alloying design can significantly improve the fracture toughness of tungsten wire. Impurities and defects are often the source of crack generation and expansion, so by controlling the purity and composition of the material, the influence of these adverse factors can be effectively reduced.

Preparation process: Heat treatment, drawing, straightening and other processes in the preparation process have an important influence on the microstructure and mechanical properties of tungsten wire. Reasonable preparation process can refine grains, eliminate internal stress, improve the uniformity and density of materials, thereby enhancing the fracture toughness of tungsten wire.

Use environment: Cut-resistant tungsten wire will be affected by various external factors during use, such as temperature, humidity, corrosive media, etc.

These factors may have an adverse effect on the fracture toughness of tungsten wire, so it is necessary to pay attention to controlling these factors when using it to protect the performance of tungsten wire.

More details of tungsten wires, please visit website: http://tungsten.com.cn/tungsten-wires.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595