The performance of cut-resistant tungsten wire under different stress environments will be affected by many factors, including stress type, stress size, duration, and the material and structure of the tungsten wire itself. The following is an analysis of the possible performance of cut-resistant tungsten wire under different stress environments:

- Tensile stress

Performance: Under tensile stress, cut-resistant tungsten wire will undergo deformation until it breaks. Since tungsten wire has a high tensile strength, it can maintain good shape stability under a small tensile stress. However, when the tensile stress exceeds the tensile strength limit of tungsten wire, the tungsten wire will break.

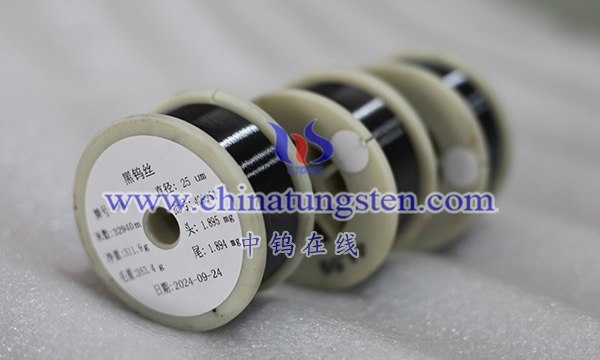

Influencing factors: The tensile strength, diameter, surface quality and other factors of tungsten wire will affect its performance under tensile stress. For example, when a tungsten wire with a smaller diameter is subjected to the same tensile stress, it is easier to reach the strength limit and break due to its smaller cross-sectional area.

- Bending stress

Performance: Under bending stress, cut-resistant tungsten wire may undergo plastic deformation or break. The magnitude and duration of bending stress will affect the degree of deformation of tungsten wire. Smaller bending stress may only cause elastic deformation of tungsten wire, while larger bending stress may cause plastic deformation or even breakage.

Influencing factors: The toughness, bending radius, bending speed and other factors of tungsten wire will affect its performance under bending stress. Tungsten wire with better toughness can absorb more energy and is not easy to break when subjected to bending stress.

- Shear stress

Performance: Under shear stress, the cut-resistant tungsten wire may be sheared and broken. Shear stress usually occurs on the contact surface between the tungsten wire and other objects, such as the contact between the blade and the tungsten wire during the cutting process.

Influencing factors: The shear strength of the tungsten wire, the friction coefficient of the contact surface, the shear speed and other factors will affect its performance under shear stress. Higher shear strength and lower friction coefficient can improve the stability of the tungsten wire under shear stress.

- Complex stress environment

In practical applications, cut-resistant tungsten wire is often in an environment where multiple stresses act simultaneously. At this time, the performance of tungsten wire will be affected by a combination of various stresses. For example, during the cutting process, the tungsten wire is not only affected by tensile stress and shear stress, but may also be affected by bending stress and thermal stress.

In a complex stress environment, the performance stability of tungsten wire will be severely tested. Therefore, when selecting cut-resistant tungsten wire, it is necessary to fully consider its comprehensive performance indicators, such as tensile strength, toughness, wear resistance, corrosion resistance and thermal stability.

- Precautions

It should be noted that the cut-resistant tungsten wires produced by different manufacturers may have differences in material, process and performance. Therefore, in specific applications, it is necessary to select suitable tungsten wire products according to actual conditions.

In addition, when using cut-resistant tungsten wire, it is also necessary to pay attention to controlling the stress size and duration to avoid exceeding the tolerance limit of the tungsten wire and causing breakage or damage.

More details of tungsten wires, please visit website: http://tungsten.com.cn/tungsten-wires.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595