The production process of cut-resistant tungsten wire is a complex and delicate process, which mainly includes raw material selection and preparation, mixing, forming, sintering, wire drawing, post-processing and testing. The following is a detailed introduction to the production process:

- Raw material selection and preparation

Raw material selection: The main raw material of cut-resistant tungsten wire is high-purity tungsten powder, and its purity has an important influence on the performance of the final product.

Preparation process: Tungsten powder can be prepared by a variety of methods, such as heating and decomposing ammonium paratungstate (APT) in a roasting furnace to produce blue crystalline tungsten oxide, and then reducing it to tungsten powder in a hydrogen reduction furnace. In order to improve the performance of tungsten wire, other alloy elements may also need to be added for doping.

- Mixing

Mix the sieve-graded tungsten powder with other alloying elements in a specific proportion. The mixing process usually uses ball milling to ensure mixing uniformity.

- Forming

Pressing: Put the mixed powder into the mold and use an isostatic press

Pressing is performed to form a tungsten billet with certain specifications and density. The grain size, density and performance of the tungsten billet made by isostatic pressing are uniform, and the billet strength is high.

- Sintering

Put the pressed tungsten billet into a sintering furnace for sintering. During the sintering process, a solid phase reaction occurs between the tungsten powder particles to form a dense tungsten bar. The sintering temperature is usually above the melting point of tungsten, and the sintering time is determined according to the process requirements. The density of the sintered tungsten bar increases, usually reaching more than 17.7g/cm³, and has good mechanical properties and processing properties.

- Wire drawing

Wire drawing: Put the sintered tungsten bar into a wire drawing machine for wire drawing. The cross-sectional area is gradually reduced by mechanical force, and the tungsten bar is drawn into a wire. Lubricants (such as graphite) are added during the wire drawing process to reduce friction and wear. After multiple wire drawing passes, the tungsten wire is drawn to the required diameter (usually between 20 microns and 1 mm).

- Post-processing and testing

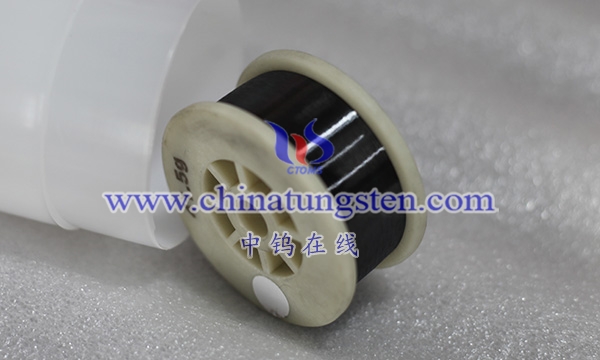

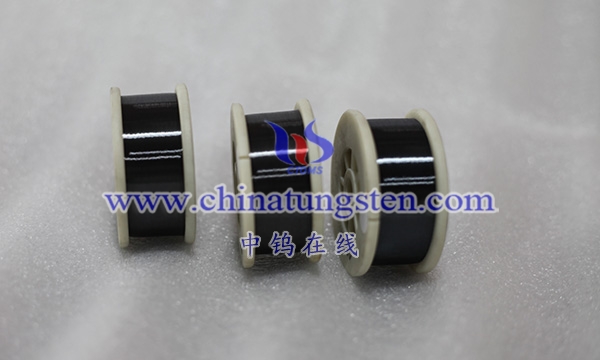

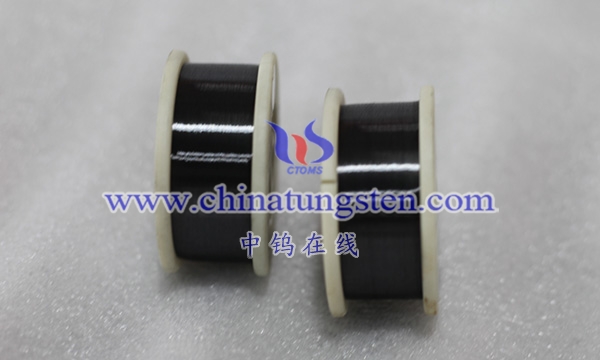

Post-processing: The drawn tungsten wire may need post-processing, such as cleaning, drying, winding and winding, etc., to ensure that its surface is clean, free of impurities, and easy to store and transport.

Testing: The quality of the produced cut-resistant tungsten wire is tested, including diameter measurement, tensile strength test, anti-sagging performance test, etc., to ensure that it meets the relevant standards and requirements.

- Special process (such as doping treatment)

In order to improve the performance of tungsten wire, such as anti-sagging and enhanced toughness, it may be necessary to dope during the raw material preparation or forming process. Doping elements may include potassium, rhenium, etc., which can be evenly mixed into tungsten powder by solution spraying, stirring, etc.

- Precautions

Safety: Safety operating procedures must be strictly followed during the production process to avoid accidents. Such as wearing protective equipment (gloves, goggles, etc.), ensuring that the work area is clean and tidy, etc.

Quality control: Each production link needs to strictly control quality to ensure that the purity of raw materials, process parameters, equipment status, etc. meet the requirements to improve the quality and performance of cut-resistant tungsten wire.

Environmental protection: Waste and exhaust gas generated during the production process need to be properly handled to meet environmental protection requirements.

More details of tungsten wires, please visit website: http://tungsten.com.cn/tungsten-wires.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595