The forming process of cut-resistant tungsten wire does require special equipment, which plays a vital role in the production process of tungsten wire. The following is a detailed explanation of the special equipment required:

- Raw material processing equipment

Screening machine: used to screen and grade tungsten powder to ensure uniform particle size distribution and provide high-quality raw materials for subsequent forming processes.

Mixer: Mix the screened tungsten powder with other alloy elements in a certain proportion, usually using ball milling to ensure the uniformity of the mixing.

- Forming equipment

Pressing machine: used to press the mixed powder into a blank with a certain shape and density. The pressing machine needs to have sufficient pressure and stability to ensure the uniformity and density of the blank.

Mold: The mold used in the pressing process needs to have precise size and shape to ensure that the pressed blank meets the requirements of subsequent processing. The material and surface quality of the mold must also meet the requirements to avoid damage to the tungsten wire.

- Sintering equipment

Sintering furnace: used to sinter the pressed blank under high temperature conditions to transform its loose structure into a dense metal structure. The sintering furnace needs to have a precise temperature control system and a stable heating environment to ensure the uniformity and consistency of the sintering process.

- Wire drawing equipment

Wire drawing machine: Wire drawing machine is one of the core equipment in the production of cut-resistant tungsten wire. It gradually draws the sintered blank into filaments through mechanical force. The wire drawing machine needs to have a stable drawing speed and processing rate control system, as well as a good lubrication and cooling system to ensure that the drawn tungsten wire has a uniform diameter and a smooth surface.

- Auxiliary equipment

Detection equipment: At different stages of tungsten wire production, various detection equipment is required to detect the quality of tungsten wire. These equipment include diameter measuring instruments, tensile strength testers, surface quality testers, etc., which are used to ensure that the various performance indicators of tungsten wire meet the standard requirements.

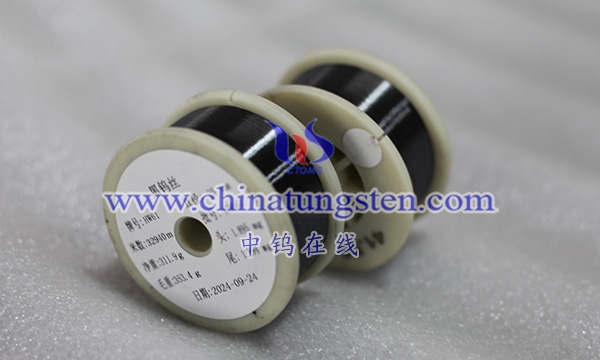

Cleaning and packaging equipment: Cleaning equipment is used to remove dirt and impurities on the surface of tungsten wire to ensure its surface finish and purity. Packaging equipment is used to vacuum pack or seal the cleaned tungsten wire to maintain its quality and long-term preservation.

More details of tungsten wires, please visit website: http://tungsten.com.cn/tungsten-wires.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595