Cut-resistant tungsten wire has many important uses in protective equipment, mainly due to its high strength, fatigue resistance, corrosion resistance and great potential for thinning. The following are the specific uses of cut-resistant tungsten wire in protective equipment:

- Cut-resistant gloves

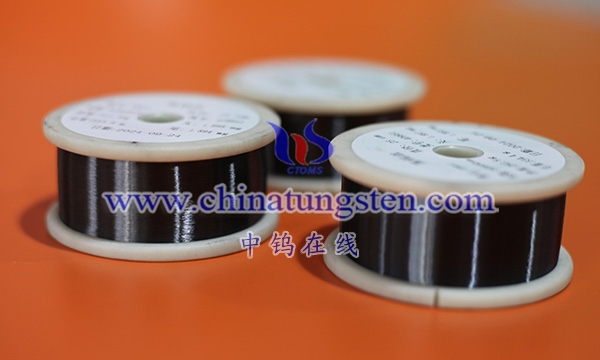

Manufacturing cut-resistant protective gloves: Tungsten wire can be processed into extremely fine specifications, and its strength and hardness have been greatly improved compared to stainless steel of similar specifications. Therefore, cut-resistant gloves made of tungsten wire can be thinner, softer and more comfortable to wear while meeting the same level of cut resistance. This kind of gloves is suitable for a variety of hand protection occasions, such as mechanical processing, glass manufacturing, food processing and other industries.

Improve the protection level: Through excellent design, tungsten wire gloves are expected to increase the cut resistance level of gloves by more than 2 levels, providing users with a higher level of hand protection.

- Other protective equipment

Although the main use of cut-resistant tungsten wire in protective equipment is to make cut-resistant gloves, its excellent physical and chemical properties also provide the possibility of its application in other protective equipment. For example, in protective scenarios that require high strength, corrosion resistance and wear resistance, tungsten wire or its composite materials can be considered to enhance the strength and durability of protective equipment. However, it should be noted that there may be relatively few cases of the application of cut-resistant tungsten wire in other specific protective equipment, which requires further research and development based on specific protection needs and product design.

- Advantages Summary

High strength and fatigue resistance: The high strength and fatigue resistance of tungsten wire enable the protective equipment made of it to withstand greater external forces and longer use, thereby extending the service life of the equipment.

Lightweight and comfort: Tungsten wire with great potential for thinning enables protective equipment to be lightweight while maintaining high strength, improving wearing comfort.

Corrosion resistance and wear resistance: The corrosion resistance and wear resistance of tungsten wire enable protective equipment to maintain stable performance in harsh working environments, reducing damage and replacement costs caused by environmental factors.

More details of tungsten wires, please visit website: http://tungsten.com.cn/tungsten-wires.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595