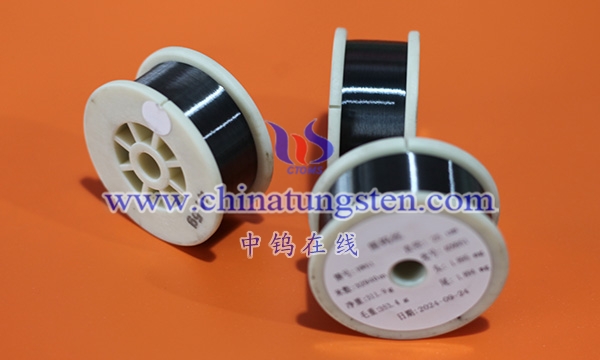

Tungsten wire is suitable for cutting tools, especially in occasions requiring high temperature, high strength and wear resistance. The following is a specific analysis of the application of tungsten wire in cutting tools:

Features and advantages

High temperature stability: Tungsten wire has an extremely high melting point (up to 3410℃), which means that it can maintain stable physical and chemical properties in high temperature environments and is not easy to melt or deform. This feature makes tungsten wire perform well in situations where high temperature cutting is required.

High strength and hardness: Tungsten wire has high tensile strength and hardness, which allows it to maintain a sharp edge during the cutting process and is not easy to wear, thereby improving cutting efficiency and precision.

Wear resistance: Due to its high hardness and good wear resistance, tungsten wire can maintain good cutting performance during long-term cutting, reduce the number of times the cutting tool is replaced, and reduce production costs.

Heat resistance: Tungsten wire can withstand high temperatures and will not deform, which allows it to remain stable during high-speed cutting and will not fail due to high temperatures.

Application examples

Metal cutting: Tungsten wire cutting machines can cut various metal materials, including steel, copper, aluminum, etc. Due to the high temperature stability and high strength of tungsten wire, it can easily cope with the cutting needs of these materials.

Precision machining: In situations where high-precision machining is required, such as semiconductors, LEDs, gemstone processing, etc., tungsten diamond wire has been widely used as a cutting tool with high hardness, high toughness and high wear resistance. It can achieve more delicate cutting cuts and improve machining quality.

Special material cutting: In addition to common metal materials, tungsten wire can also be used to cut some special materials, such as ceramics, glass, etc. These materials usually have high hardness and brittleness, and the high hardness and wear resistance of tungsten wire enable it to maintain stable cutting performance during the cutting process of these materials.

Precautions

Although tungsten wire has many advantages in cutting tools, there are also some issues that need to be noted:

Brittleness: Tungsten wire is more likely to break during machining and is difficult to weld. Therefore, when designing and using tungsten wire cutting tools, its brittle characteristics need to be considered to avoid excessive stress concentration and impact.

Cost: Compared with other cutting tool materials, tungsten wire is more expensive. Therefore, when selecting cutting tool materials, it is necessary to make comprehensive considerations based on actual needs and cost budgets.

More details of tungsten wires, please visit website: http://tungsten.com.cn/tungsten-wires.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595