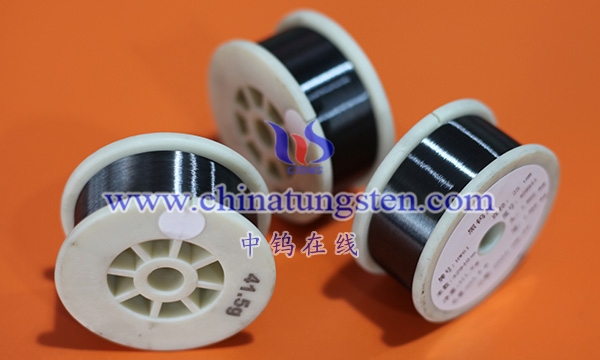

Tungsten wire performs quite well in cutting hard materials, mainly due to its unique physical and chemical properties. The following is a detailed analysis of the performance of tungsten wire in cutting hard materials:

- High strength and wear resistance

High strength: Tungsten wire has high tensile strength and can withstand large mechanical stress during cutting, ensuring cutting stability and precision.

Wear resistance: Tungsten wire has excellent wear resistance and can maintain a low wear rate when cutting hard materials for a long time, extending its service life.

- High melting point and thermal stability

High melting point: The melting point of tungsten wire is as high as 3410℃, which enables it to maintain stable physical and chemical properties in high temperature environments and is not easy to melt or deform.

Thermal stability: Tungsten wire can still maintain good hardness and strength at high temperatures, which is especially important for cutting hard materials that require high temperature treatment.

- Excellent conductivity

In some cutting technologies, such as wire cutting, tungsten wire as an electrode wire needs to transmit current to generate electric sparks for cutting. The good conductivity of tungsten wire ensures the effective transmission of current and improves cutting efficiency and precision.

- Cutting application examples

Electrodischarge wire cutting: Tungsten wire is a key material in electrodischarge wire cutting technology. Through high-speed reciprocating motion, electric spark discharge is generated between the tungsten wire and the workpiece, achieving precise cutting of hard materials. The high strength and wear resistance of tungsten wire enable it to maintain stable performance during this high-load cutting process.

Other cutting technologies: Although the application of tungsten wire in other cutting technologies may not be as extensive as electrodischarge wire cutting, its unique properties still make it an ideal choice for cutting hard materials in certain specific occasions.

- Precautions

Although tungsten wire has many advantages in cutting hard materials, it is brittle and prone to breakage during processing. Therefore, when using tungsten wire for cutting, appropriate measures need to be taken to reduce the risk of breakage, such as controlling the cutting speed and selecting appropriate cutting parameters.

In addition, the price of tungsten wire is relatively high, which may increase the cutting cost. Therefore, when choosing cutting materials, it is necessary to make comprehensive considerations based on specific needs and cost budgets.

More details of tungsten wires, please visit website: http://tungsten.com.cn/tungsten-wires.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595