Tungsten wire can indeed be used as an electrode material for laser cutting. This is mainly based on several key characteristics of tungsten wire:

High melting point: The melting point of tungsten wire is very high, which can withstand the high temperature generated during laser cutting, ensuring that the electrode is not easy to melt or deform during long-term use.

Good conductivity: Tungsten wire has good electrical conductivity, which enables it to effectively transmit current during laser cutting, thereby initiating and maintaining the required arc discharge.

Corrosion resistance: Tungsten wire has good corrosion resistance to a variety of chemicals and can maintain stable performance in harsh cutting environments.

Withstand arc corrosion: Tungsten wire can withstand arc corrosion, which is an important characteristic that electrode materials must have in welding and cutting processes such as laser cutting.

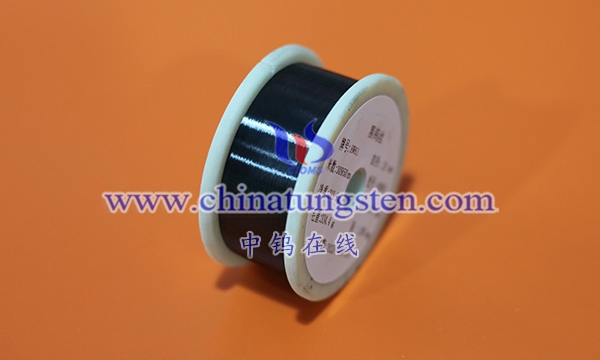

More details of tungsten wires, please visit website: http://tungsten.com.cn/tungsten-wires.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595