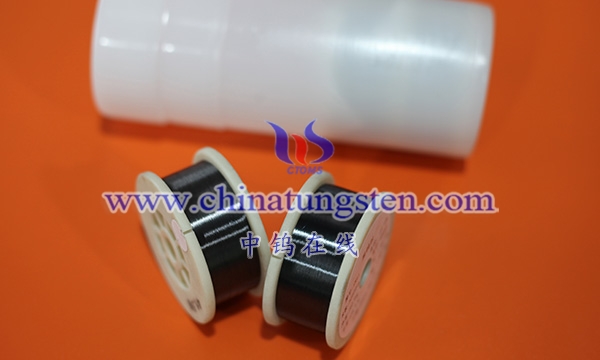

Tungsten wire can indeed be used to enhance the strength of building materials. The following is a detailed explanation of this point of view:

- Physical properties of tungsten wire

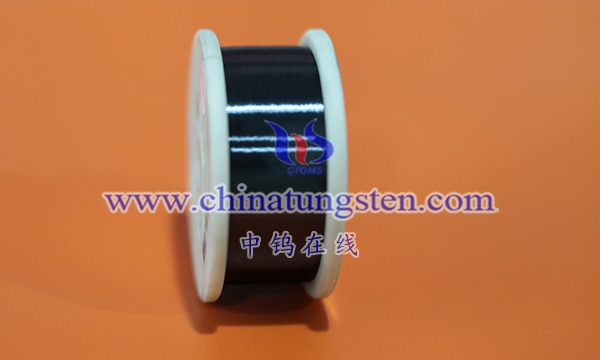

Tungsten is a metal with a high melting point (3422℃), high density and high strength. These characteristics give tungsten wire a unique advantage in the reinforcement of building materials. The strength of tungsten wire is particularly high, thanks to its tightly ordered crystal structure and large tungsten atoms, which are arranged very closely. These characteristics give tungsten wire a greater elastic modulus and yield strength.

- Application of tungsten wire in building materials

Reinforced composite materials:

Tungsten wire can be added to building materials such as concrete, ceramics or metal-based composites as a reinforcing phase. Through reasonable design and preparation process, tungsten wire can effectively improve the strength and toughness of these composite materials.

For example, adding tungsten wire to concrete can form a concrete composite material with high strength and high toughness. When this composite material is subjected to external force, tungsten wire can absorb and disperse energy, thereby improving the crack resistance and durability of concrete.

Manufacture of high-strength structural parts:

Tungsten wire can also be used to manufacture high-strength structural parts, such as load-bearing components in buildings, rigging for bridges, etc. These structural parts need to withstand huge external forces and loads, and the high strength and high density of tungsten wire make it an ideal material choice.

By weaving tungsten wire into a mesh or compounding it with other materials, a structural member with high strength and good toughness can be formed, thereby improving the overall stability and safety of the building.

- Advantages of tungsten wire reinforced building materials

Increase strength:

The high strength characteristics of tungsten wire make it an ideal choice for enhancing the strength of building materials. By adding tungsten wire, the tensile, compressive and shear strength of building materials can be significantly improved.

Improve durability:

Tungsten wire has good corrosion resistance and oxidation resistance, which can effectively extend the service life of building materials. In harsh environments, such as high temperature, humidity or corrosive environments, tungsten wire reinforced building materials can maintain their stability and performance.

Reduce weight:

Although tungsten wire has a high density, due to its high strength characteristics, the overall weight of building materials can be reduced while ensuring strength. This is of great significance for reducing the burden on building structures and improving the earthquake resistance and wind resistance of buildings.

- Practical application cases

In the field of construction, the strength and corrosion resistance of tungsten make it an ideal material for manufacturing special building materials. For example, in buildings that require high safety, such as nuclear power plants, tungsten alloys can be used as a protective layer to effectively resist the damage of nuclear radiation. In addition, tungsten wire can also be used to manufacture high-precision measuring tools, such as vernier calipers, micrometers, etc., which provides strong support for precise construction in the construction industry.

More details of tungsten wires, please visit website: http://tungsten.com.cn/tungsten-wires.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595