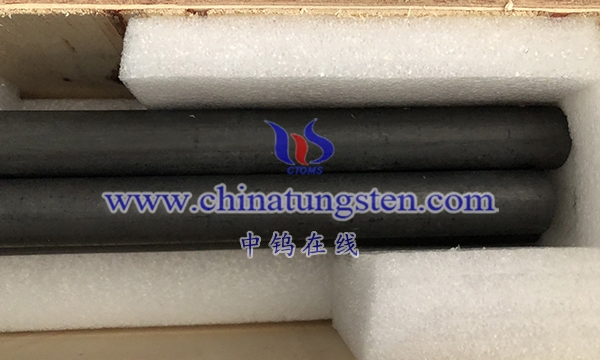

TZM alloy rods are widely used in vacuum furnaces. Due to its excellent high temperature performance and good mechanical properties, TZM alloy rods are commonly used in the following fields and applications in vacuum furnaces:

High-temperature heating element: Due to the high melting point, thermal corrosion resistance and excellent high-temperature resistance of the TZM alloy rod, it can be used as a high-temperature heating element in a vacuum furnace, such as heating wire, heater, heating electrode, etc. It is able to withstand thermal cycling and thermal stress in high temperature environments while providing stable heating.

Internal components of vacuum furnace: TZM alloy rods can be used to make components in vacuum furnaces, such as furnace brackets, fixtures, furnace doors, support rods, etc. It has high mechanical strength and corrosion resistance, and can withstand stress and load under high temperature and vacuum environment in the vacuum furnace.

Vacuum heat treatment process: Vacuum heat treatment is a heat treatment process carried out in an oxygen-free or low-oxygen environment, which can provide a purer, non-oxidative heat treatment environment. TZM alloy rods can be used for heating and protection in vacuum heat treatment processes, such as playing a key role in vacuum annealing, vacuum quenching and vacuum sintering processes.

Vacuum evaporation and deposition: In the vacuum evaporation and deposition process, TZM alloy rods can be used as substrates or support rods to support and fix the growth and deposition process of thin film materials. Its high temperature stability and corrosion resistance make it suitable for the requirements of withstanding high temperature and chemical reaction in vacuum environment.

More details of molybdenum or molybdenum alloy products, please visit website: http://molybdenum-alloy.com/index.html

Please contact CHINATUNGSTEN for inquiry and order of molybdenum alloy products:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595