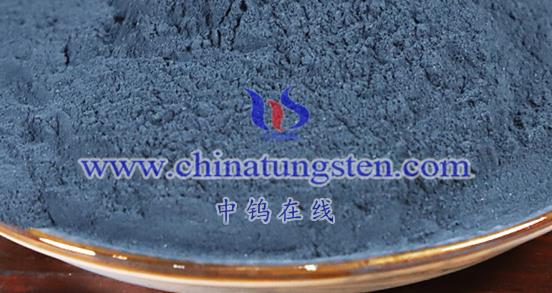

Nano Cesium Tungsten Bronze aqueous dispersion, as a nano material solution with special properties, has a range of significant advantages, but also some drawbacks. Here is a detailed analysis of its advantages and disadvantages:

Advantages:

- Excellent thermal insulation performance: Nano Cesium Tungsten Bronze has strong absorption characteristics in the near-infrared region (especially in the 950-1400nm wavelength range), while maintaining high transmittance in the visible light region (such as at 550nm). This characteristic makes Nano Cesium Tungsten Bronze aqueous dispersion particularly advantageous in the preparation of transparent thermal insulation materials. It effectively blocks heat transfer without affecting lighting conditions. This excellent thermal insulation performance makes it widely applicable in fields such as construction, automotive, and electronic devices.

- Good stability: Nano Cesium Tungsten Bronze particles show good stability in the dispersion liquid, which is not prone to sedimentation or aggregation. This stability ensures that the nanoparticles can maintain an even dispersion state over long periods, improving stability and reliability in various applications. Good stability also means the dispersion liquid is less likely to deteriorate during storage and use, thus extending its shelf life.

- Uniform particle distribution: Nano Cesium Tungsten Bronze particles are evenly dispersed in the liquid, avoiding aggregation between particles. This uniform distribution helps maintain the stability and consistency of the material’s properties. It also improves the flatness and gloss of the coating, enhancing its appearance quality.

- Environmental friendliness and safety: Nano Cesium Tungsten Bronze aqueous dispersion is relatively environmentally friendly and safe during preparation and use. It does not pose significant harm to the environment or human health. This aligns with modern industrial requirements for green and sustainable development.

- Adjustable solid content: The solid content of Nano Cesium Tungsten Bronze aqueous dispersion can be customized according to specific needs, with a maximum content of 50%. This adjustability allows the dispersion liquid to meet different material performance requirements in various application scenarios.

Disadvantages:

- Complex preparation process: The preparation of Nano Cesium Tungsten Bronze aqueous dispersion requires advanced processes and technologies, including raw material preparation, dispersant selection, and dispersion process control. These steps have high requirements for process conditions, which increases the difficulty and cost of preparation.

- High raw material cost: As a high-performance material, Nano Cesium Tungsten Bronze has relatively high raw material costs. This limits the application of Nano Cesium Tungsten Bronze aqueous dispersion in low-cost fields to some extent.

- Non-continuous operation: In certain preparation processes, such as ball milling, due to the limitations of equipment and working principles, continuous operation may not be feasible. This reduces production efficiency and may increase energy consumption and costs.

- Noise pollution: During preparation using processes like ball milling, the collisions between balls and the sound of grinding walls can produce significant noise pollution. Noise reduction measures must be implemented during production.

- Pollution risk: Since the ball milling media and other auxiliary materials might come into contact with the Nano Cesium Tungsten Bronze particles during the preparation process, there is a risk of contamination. Strict process controls and effective pollution control measures are needed during preparation to avoid contamination.

Conclusion:

Nano Cesium Tungsten Bronze aqueous dispersion offers excellent thermal insulation performance, good stability, and uniform particle distribution, among other advantages. However, it also has drawbacks such as a complex preparation process, high raw material costs, and limitations in continuous operation. These factors should be carefully considered when selecting and applying the dispersion in various practical scenarios.

More details of tungsten oxide product, please visit website: tungsten-oxide.com

Please contact CHINATUNGSTEN for inquiry and order of tungsten oxide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595