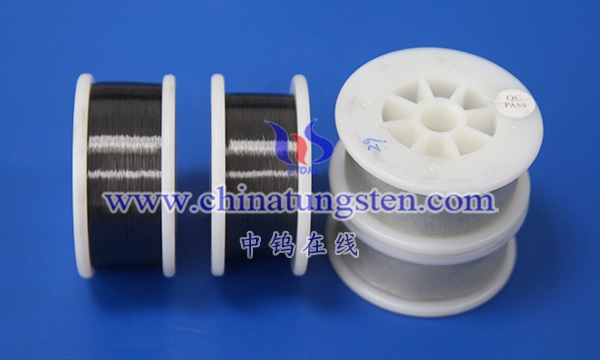

Tungsten wire is very suitable for electrolytic polishing process. The following is a detailed explanation of this point of view:

- Characteristics of tungsten wire

Tungsten is a rare metal with high melting point, high boiling point, high hardness and high strength. These characteristics make tungsten wire have significant advantages in electrolytic polishing process. In particular, its high hardness and high strength enable tungsten wire to maintain good shape stability and wear resistance during polishing.

- Principles and advantages of electrolytic polishing process

Electrolytic polishing is a method of polishing the surface of a workpiece using electrochemical principles. During the electrolytic polishing process, the workpiece is used as an anode, immersed in an electrolyte, and a certain voltage is applied. When the current passes through, the oxides and impurities on the surface of the workpiece undergo an electrochemical reduction reaction and are gradually dissolved, thereby achieving the polishing effect.

The electrolytic polishing process has the advantages of high production efficiency, simple and convenient operation, low material loss, and the ability to process workpieces of complex shapes. These advantages make electrolytic polishing an important process method in metal surface treatment.

- Application of tungsten wire in electrolytic polishing

Due to the above excellent characteristics of tungsten wire, it is very suitable for electrolytic polishing process. In practical applications, tungsten wire can be used as an anode material to remove oxides and impurities on its surface through electrolytic polishing to improve the surface finish and quality.

Especially in the manufacture of some precision devices, such as the cathode ray tube (CRT) in the picture tube of a TV, tungsten wire electrolytic polishing can effectively improve the sensitivity and stability of tungsten wire, thereby improving the display quality of CRT. In addition, tungsten wire electrolytic polishing is also widely used in the manufacture of high-end consumer goods such as jewelry, watches, and knives. It has good polishing effect, high surface flatness, and high brightness, which can add added value to the product.

- Selection of electrolytic polishing process parameters

When performing tungsten wire electrolytic polishing, it is necessary to select appropriate process parameters, such as polishing voltage, temperature, time, and composition of the electrolyte. The selection of these parameters should be determined according to the specific polishing requirements and the characteristics of the tungsten wire. By optimizing the process parameters, the best polishing effect can be obtained.

More details of tungsten wires, please visit website: http://tungsten.com.cn/tungsten-wires.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595