Tungsten wire is widely used in many fields due to its high melting point, high hardness, good electrical conductivity and thermal conductivity, but in wind power generation equipment, tungsten wire is not directly used as a core component or main material. Wind power generation equipment mainly uses wind energy to generate electricity. Its core components include wind turbines, blades, gearboxes, generators, etc. The material selection of these components is mainly based on strength, corrosion resistance, wear resistance, lightweight and other factors.

Although tungsten wire is not directly used in the main components of wind power generation equipment, tungsten metal and its alloys have important applications in high-temperature alloys, cemented carbides and other fields. These alloys may be indirectly used in certain key components of wind power generation equipment to improve their high temperature resistance, corrosion resistance and wear resistance. For example, some parts of wind turbines that work in high temperature environments may use high temperature alloys containing tungsten.

In addition, it is worth noting that although tungsten wire is not directly used in wind power generation equipment, wind power generation, as an important part of renewable energy, is complementary to the application and development trend of rare metals such as tungsten. With the global attention and investment in renewable energy, clean energy industries such as wind power generation will usher in a broader development prospect, which will also drive the progress of related materials science and technology, including the application and development of rare metals such as tungsten.

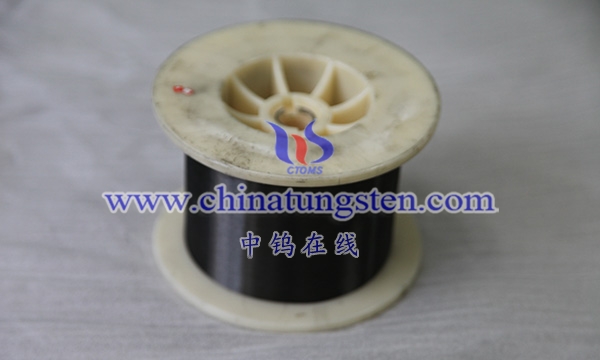

More details of tungsten wires, please visit website: http://tungsten.com.cn/tungsten-wires.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595