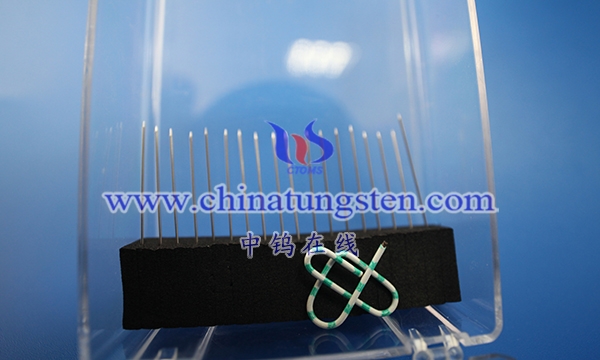

Tungsten carbide needles have excellent properties such as high hardness, high melting point, wear resistance, corrosion resistance and high temperature stability, so they are widely used in some special industrial applications, including:

Manufacture of molds: Due to their high hardness and good wear resistance, tungsten carbide needles are widely used in the manufacture of molds, such as plastic molds, die-casting molds, extrusion molds, hot-pressing molds, etc.

Manufacture of cutting tools: Due to its high hardness, good wear resistance, and good thermal stability, tungsten carbide needles are widely used in the manufacture of cutting tools, such as knives, planers, milling cutters, drills, etc.

Manufacture of thermal resistance wire: Because of its high melting point and high temperature stability, tungsten carbide needles are widely used in the manufacture of thermal resistance wire, such as electric furnace heaters, thermocouples, electric heating tubes, etc.

Manufacture of vacuum electronic devices: Due to the small thermal expansion coefficient and good thermal conductivity of tungsten carbide needles, they are widely used in the manufacture of vacuum electronic devices, such as electron tube cathodes and cathode wires.

Manufacture of aero-engine parts: Tungsten carbide needles are widely used in the manufacture of aero-engine parts, such as turbine blades and combustion chamber parts, due to their high strength, high temperature stability and good corrosion resistance.

More details of tungsten needles, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595