Preface

The purpose and significance of writing the book “High Purity Tungsten Oxide: Physical and Chemical Science, Production and Application”

The purpose of writing this book, “High-Purity Tungsten Oxide: Science and Applications”, is to systematically sort out the scientific basis, technological progress and wide application of high-purity tungsten oxide (WO₃ ) in many fields, and to provide a comprehensive and authoritative reference guide for researchers, engineers and industry practitioners. As a functional material with unique physical and chemical properties, high-purity tungsten oxide has become a star material in the field of materials science and nanotechnology due to its high purity (usually >99.95%), adjustable band gap (2.2-2.8 eV), excellent electrical and optical properties, and special effects at the nanoscale. Whether it is traditional tungsten material production or emerging photocatalytic, electrochromic, sensor and biomedical applications, high-purity WO₃ has demonstrated irreplaceable value.

The purpose of writing this book is not only to summarize the existing knowledge, but also to fill the gap between the research and application of high-purity tungsten oxide . At present, despite the surge in the number of research literature and patents related to WO₃ , there is still a lack of monographs that systematically integrate its basic theories, preparation techniques, characterization methods and application scenarios. This book strives to provide readers with a complete knowledge framework from theory to practice through an in-depth analysis of the structure and properties of high-purity WO₃ , the preparation of variants (such as yellow, blue, purple and orange tungsten oxide), and industrial challenges . In addition, this book pays special attention to the effect of high purity on the improvement of material performance, exploring its potential in future technologies such as quantum optics, space applications and smart materials, aiming to promote WO₃ from the laboratory to a wider industrialization.

The significance of this book is also reflected in its interdisciplinary nature. The application of high-purity tungsten oxide spans the fields of materials science, chemical engineering, energy technology, environmental science, electronic engineering and biomedicine. Its research is not only a breakthrough in a single discipline, but also a model of collaborative innovation in multiple fields. Through this book, we hope to stimulate readers’ interest in high-purity WO₃ , promote in-depth cooperation between academia and industry, and jointly promote the further development of this material.

Research Background and Development History of High Purity Tungsten Oxide

The history of research and application of high-purity tungsten oxide can be traced back to the beginning of the industrialization of tungsten materials in the late 19th century. Tungsten element (W, atomic number 74) was used to make filaments and alloys as early as the early 1900s due to its high melting point (3422°C) and excellent mechanical properties. However, tungsten oxide (WO₃ ), as a precursor of tungsten materials , was initially regarded only as an intermediate product in the metallurgical process, and its own functional properties did not attract widespread attention. It was not until the mid-20th century, with the rise of semiconductor technology and photochemical research, that the optical and electrical properties of WO₃ began to be explored in depth. In the 1950s, scientists discovered that WO₃ has wide-bandgap semiconductor properties (about 2.6-2.8 eV) and exhibits certain catalytic activity under light. This discovery laid the foundation for its subsequent applications.

The real rise of high-purity tungsten oxide is closely related to the development of nanotechnology. In the 1990s, the upsurge of nanomaterial research promoted the refined preparation and performance optimization of WO₃ . Through hydrothermal method, vapor deposition method and other techniques, researchers successfully prepared high-purity WO₃ nanoparticles with a particle size of less than 100 nm, and their specific surface area (20-60 m ² /g), photocatalytic efficiency and conductivity were significantly improved. At the same time, the advancement of oxygen vacancy regulation technology has spawned a variety of variants of WO₃ , such as blue tungsten oxide (WO ₂ .₉ ), purple tungsten oxide (WO ₂.₇₂ ) and orange tungsten oxide (WO ₂.₉₀ ). These non-stoichiometric materials have broadened the application scenarios of WO₃ due to differences in color, band gap and electrical properties. For example, blue and purple WO₃ are favored in tungsten powder production due to their fast reduction rates, while yellow WO₃ is the first choice in photocatalytic research due to its high stability.

Entering the 21st century, the research on high-purity WO₃ entered a period of rapid development. After 2000, with the intensification of the energy crisis and environmental problems, the application of WO₃ in photocatalytic water decomposition, pollutant degradation and electrochromic smart windows has received widespread attention. Since 2010, further breakthroughs in nanotechnology have made the functions of WO₃ more diversified. For example, its applications in supercapacitors, gas sensors and biomedical fields have gradually emerged. At the same time, advances in high-purity preparation technology (such as impurity control to the ppm level) have significantly improved the performance stability of WO₃ , promoting it from laboratory research to industrial production. In recent years, the potential of WO₃ in cutting-edge fields such as quantum optics, space thermal control and smart textiles has also been initially explored, heralding its unlimited possibilities in the future.

Looking at the development history of high-purity tungsten oxide, its evolution from a single metallurgical raw material to a multifunctional nanomaterial reflects the co-evolution of science and technology. Based on this historical background, this book attempts to present the full picture of high-purity WO₃ to readers and look forward to its role in future technological innovation.

Target Audience and User Guide

This book is broad, covering professionals and learners in a variety of fields:

Researchers

engaged in materials science, chemistry, physics and nanotechnology research, this book provides detailed information on the structure and properties of high-purity WO₃ ( Chapter 2), preparation methods (Chapter 3) and characterization techniques (Chapter 4), which can be used as a reference for theoretical research and experimental design. At the same time, the systematic comparison of WO₃ variants in Chapter 5 and the application discussion in Chapter 6 help inspire new research directions.

Engineers and technicians

For engineers and technicians engaged in the production of tungsten materials, photocatalytic equipment, sensor design or energy storage device development, the industrialization technology in Chapter 7 and the specific application scenarios in Chapter 6 (such as tungsten powder production and gas sensors) provide practical guidance. In addition, the standards and specifications in Chapter 8 can help ensure that products meet international and local requirements.

Students and Educators

For senior undergraduates, graduate students, and educators in materials science, chemical engineering, or related fields, this book’s progressive structure from basic knowledge to cutting-edge applications is suitable for teaching and learning. The first five chapters can be used as an introductory textbook, and the application part of Chapter 6 can be used for case teaching or reference for paper topic selection.

Industry decision makers and investors

For investors or business managers who are interested in the new materials industry, this book provides an analysis of the technical potential, market applications, and future trends of high-purity WO₃ (Chapters 6 and 7), which helps to assess its commercial value and technical risks.

CONTENT

Preface

Research Background and Development History of High Purity Tungsten Oxide

Target Audience and User Guide

Chapter 1: Overview of High Purity Tungsten Oxide

1.1 Definition and classification of high purity tungsten oxide

1.1.1 Chemical composition and purity standards

1.1.2 Non-stoichiometric variants of tungsten oxide (WO₃₋ₓ )

1.1.3 The difference between high purity and ordinary tungsten oxide

1.2 History and Development of High Purity Tungsten Oxide

1.2.1 Early Discovery and Industrial Application

1.2.2 Breakthroughs in the Nanotechnology Era

1.3 The Importance of High Purity Tungsten Oxide

1.3.1 Status in Materials Science

1.3.2 Driving factors of industrial and technological applications

Chapter 2: Structure and Properties of High Purity Tungsten Oxide

2.1 Crystal structure

2.1.1 Monoclinic, orthorhombic and cubic phases

2.1.2 Effect of oxygen vacancies on structure

2.1.3 XRD characterization and lattice parameters

2.2 Physical properties

2.2.1 Density and thermodynamic properties

2.2.2 Optical properties (band gap, absorption spectrum)

2.2.3 Electrical properties (conductivity, carrier concentration)

2.3 Chemical properties

2.3.1 Redox characteristics

2.3.2 Surface chemistry and adsorption behavior

2.3.3 Effect of high purity on chemical stability

2.4 Nanoscale properties

2.4.1 Specific surface area and pore structure

2.4.2 Quantum Effects and Size Dependence

Chapter 3: Preparation Method of High Purity Tungsten Oxide

3.1 Chemical Vapor Deposition (CVD)

3.1.1 Process principle and equipment

3.1.2 Parameter optimization and purity control

3.1.3 Film and powder preparation cases

3.2 Hydrothermal and solvothermal methods

3.2.1 Reaction mechanism and conditions

3.2.2 Morphology Control of Nanostructures

3.2.3 Key technologies for achieving high purity

3.3 Precipitation method

3.3.1 Raw material selection and reaction process

3.3.2 Impurity separation and purification

3.3.3 Feasibility of industrial production

3.4 High temperature solid phase method

3.4.1 Calcination and reduction process

3.4.2 Atmosphere Control and Purity Assurance

3.4.3 Preparation of blue, purple and orange tungsten oxide

3.5 Other emerging methods

3.5.1 Plasma treatment

3.5.2 Sol-gel method

3.5.3 Microwave-assisted synthesis

3.6 Comparison of preparation methods

3.6.1 Trade-off between purity and yield

3.6.2 Cost and scalability analysis

Chapter 4: Characterization Technology of High Purity Tungsten Oxide

4.1 Structural characterization

4.1.1 X-ray diffraction (XRD)

4.1.2 Raman spectroscopy

4.1.3 Transmission Electron Microscope (TEM) and Scanning Electron Microscope (SEM)

4.2 Chemical composition analysis

4.2.1 X-ray Photoelectron Spectroscopy (XPS)

4.2.2 Inductively coupled plasma optical emission spectroscopy (ICP-OES)

4.2.3 Fourier Transform Infrared Spectroscopy (FTIR)

4.3 Physical performance test

4.3.1 Specific surface area and pore analysis (BET)

4.3.2 Ultraviolet-visible spectroscopy (UV-Vis)

4.3.3 Four-probe method and conductivity measurement

4.4 Nano-characteristic analysis

4.4.1 Dynamic Light Scattering (DLS) and Particle Size Distribution

4.4.2 Thermogravimetric analysis (TGA) and differential scanning calorimetry (DSC)

4.5 Interpretation and application of characterization results

4.5.1 Quantitative analysis of oxygen vacancies and defects

4.5.2 High Purity Verification Method

Chapter 5: Variants of High Purity Tungsten Oxide

5.1 Yellow Tungsten Oxide (YTO)

5.1.1 Structure and properties

5.1.2 Preparation method

5.1.3 Application areas

5.2 Blue Tungsten Oxide (BTO)

5.2.1 Structure and properties

5.2.2 Preparation method

5.2.3 Application areas

5.3 Violet Tungsten Oxide (VTO)

5.3.1 Structure and properties

5.3.2 Preparation method

5.3.3 Application areas

5.4 Orange Tungsten Oxide (OTO)

5.4.1 Structure and properties

5.4.2 Preparation method

5.4.3 Application areas

5.5 Comparison between variants

5.5.1 Effect of oxygen vacancy concentration

5.5.2 Differences in optical and electrical properties

5.5.3 Applicability of application scenarios

Chapter 6: Application of High Purity Tungsten Oxide

6.1 Tungsten Material Production

6.1.1 Preparation of high purity tungsten powder

6.1.1.1 Electron emission materials

6.1.1.2 Tungsten target production

6.1.1.3 Tungsten wire and filament manufacturing

6.1.2 Cemented Carbide and High-temperature Alloys

6.1.2.1 Cutting tools

6.1.2.2 Aerospace components

6.1.2.3 Wear-resistant coating

6.1.2.4 Military materials

6.1.3 Future Potential

6.1.3.1 Ultrafine tungsten powder and 3D printing

6.1.3.2 High Entropy Alloys

6.1.3.3 Tungsten-based composite materials

6.1.3.4 Green Metallurgical Technology

6.2 Photocatalysis and environmental applications

6.2.1 Photocatalytic water splitting and hydrogen production

6.2.1.1 Hydrogen fuel production

6.2.1.2 Portable energy devices

6.2.1.3 Industrial by-product hydrogen recovery

6.2.2 Pollutant degradation and air purification

6.2.2.1 Wastewater treatment

6.2.2.2 Air purification equipment

6.2.2.3 Industrial waste gas treatment

6.2.2.4 Degradation of agricultural residues

6.2.3 Future Potential

6.2.3.1 CO₂ conversion

6.2.3.2 Self-cleaning surfaces

6.2.3.3 Antimicrobial purification

6.2.3.4 Photocatalytic fuel cells

6.2.3.5 Environmental monitoring and remediation

6.3 Electrochromic and Smart Materials

6.3.1 Smart windows and display devices

6.3.1.1 Building Energy-Saving Windows

6.3.1.2 Car rearview mirror

6.3.1.3 Flexible Display Screen

6.3.1.4 Aviation windows

6.3.2 Electrochromic performance optimization

6.3.2.1 Electronic tags

6.3.2.2 Smart glasses

6.3.2.3 Dynamic billboards

6.3.2.4 Military camouflage

6.3.3 Future Potential

6.3.3.1 Multicolor color change

6.3.3.2 Flexible smart materials

6.3.3.3 Coordinated control of heat and electricity

6.3.3.4 Adaptive optics

6.3.3.5 Neural Interface Visualization

6.4 Sensor Technology

6.4.1 Gas Sensor

6.4.1.1 Environmental monitoring

6.4.1.2 Industrial safety

6.4.1.3 Automobile exhaust gas detection

6.4.1.4 Indoor air testing

6.4.2 Electrochemical Sensors

6.4.2.1 Water quality monitoring

6.4.2.2 Food safety testing

6.4.2.3 Medical diagnosis

6.4.2.4 Industrial process control

6.4.3 Future Potential

6.4.3.1 Multifunctional Sensor

6.4.3.2 Wearable Sensors

6.4.3.3 Self-powered sensors

6.4.3.4 Neural Sensors

6.4.3.5 Miniaturization and Integration

6.5 Energy Storage and Energy Conversion

6.5.1 Supercapacitors and Batteries

6.5.1.1 Portable electronic devices

6.5.1.2 Electric vehicle energy storage

6.5.1.3 Renewable energy storage

6.5.1.4 Microbattery Improvement

6.5.2 Photothermal conversion and solar energy utilization

6.5.2.1 Solar water heaters

6.5.2.2 Building Heating

6.5.2.3 Solar thermal power generation

6.5.2.4 Textile heating

6.5.3 Future Potential

6.5.3.1 Solid-state batteries

6.5.3.2 Thermoelectric materials

6.5.3.3 Photovoltaic and storage integration

6.5.3.4 Flexible energy storage

6.5.3.5 Nuclear Assisted Heat Transfer

6.6 Optical and Electronic Applications

6.6.1 Optical coatings and filters

6.6.1.1 Laser protection

6.6.1.2 Photographic Filters

6.6.1.3 Anti-reflective coating

6.6.1.4 Thermal Mirror Applications

6.6.2 Semiconductor devices

6.6.2.1 Photodetector

6.6.2.2 Field Effect Transistor

6.6.2.3 Flexible Circuits

6.6.2.4 Memory Manufacturing

6.6.3 Future Potential

6.6.3.1 Quantum Optics

6.6.3.2 Transparent Conductive Film

6.6.3.3 Photonic Crystals

6.6.3.4 Nonlinear optics

6.6.3.5 Holographic Storage

6.7 Biomedical and Health Applications

6.7.1 Antibacterial and Disinfection

6.7.1.1 Medical device coatings

6.7.1.2 Water purification and disinfection

6.7.1.3 Air disinfection

6.7.1.4 Food packaging

6.7.2 Drug delivery and imaging

6.7.2.1 Targeted cancer therapy

6.7.2.2 Bioimaging probes

6.7.2.3 Gene delivery

6.7.2.4 Wound healing

6.7.3 Future Potential

6.7.3.1 Photodynamic therapy

6.7.3.2 Biosensors

6.7.3.3 Tissue engineering

6.7.3.4 Neural repair

6.7.3.5 Materials for implantation

6.8 Other Emerging Applications

6.8.1 Catalyst carrier

6.8.1.1 Exhaust gas purification

6.8.1.2 Chemical synthesis

6.8.1.3 Fuel cells

6.8.1.4 Photocatalytic synergy

6.8.2 Radiation shielding

6.8.2.1 Medical protection

6.8.2.2 Nuclear industry shielding

6.8.2.3 Space Detection

6.8.2.4 Industrial testing

6.8.3 Future Potential

6.8.3.1 Space thermal control coatings

6.8.3.2 Smart Textiles

6.8.3.3 Quantum Storage

6.8.3.4 Acoustic materials

6.8.3.5 Energy harvesting

6.9 Application Summary and Outlook

6.9.1 Overview of existing applications

6.9.2 Future Trends

6.9.2.1 Multifunctional Integration

6.9.2.2 Green Technology

6.9.2.3 Nanotechnology and Intelligence

6.9.2.4 Cross-domain expansion

6.9.3 Technical Challenges and Countermeasures

Chapter 7: Industrialization and Technical Challenges of High-Purity Tungsten Oxide

7.1 Industrial production process

7.1.1 Raw material purification and processing

7.1.2 Large-scale preparation technology

7.2 Purity Control and Quality Assurance

7.2.1 Impurity detection and removal

7.2.2 Quality certification and standards

7.3 Technical Challenges and Solutions

7.3.1 Thermal stability and oxidation issues

7.3.2 Nanoscale dispersion and agglomeration control

7.3.3 Cost optimization and environmental protection requirements

7.4 Future Development Direction

7.4.1 New Technology and Intelligent Production

7.4.2 Exploration of the high purity limit

Chapter 8: Standards and Specifications for High Purity Tungsten Oxide

8.1 Chinese Standards

8.1.1 GB/T 32698-2016 Nano-tungsten oxide powder

8.1.2 GB/T 42272-2022 Evaluation of photocatalytic performance of nanomaterials

8.2 International Standards

8.2.1 ISO 9277:2022 BET surface area determination

8.2.2 ISO/TS 80004-1:2015 Nanotechnology Terminology

8.3 Standards Application and Compliance

8.3.1 Selection of detection methods

8.3.2 Coordination between international standards and localization

Appendix

Appendix A: Glossary of terms related to high purity tungsten oxide

Chinese, English, Japanese and Korean multi-language comparison

Appendix B: Experimental plan for the preparation of high purity tungsten oxide

Examples of laboratory and industrial processes

Appendix C: List of patents related to high purity tungsten oxide

Patent number, title and abstract

Appendix D: List of Standards for High Purity Tungsten Oxide

Comparison with Chinese, Japanese, German, Russian, Korean and international standards

Appendix E: High Purity Tungsten Oxide References

Academic papers, patents, standards and books

READ MORE: High Purity Tungsten Oxide Physical, Chemical, Processing & Application

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

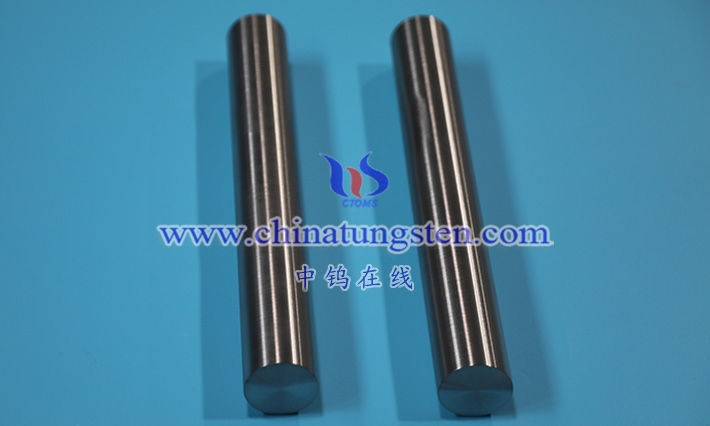

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

For more information about tungsten chemical products please visit the website: tungsten-powder.com

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595