Preface

Blue tungsten oxide (Blue Tungsten Oxide, referred to as blue tungsten, the chemical formula is usually WO₂.₉ or W₂₀O₅₈ ), as a non-stoichiometric oxide, occupies an important position in materials science, chemical engineering and industrial production due to its unique oxygen defect structure, optical properties and electrochemical properties. Since its first industrial application as an intermediate in the tungsten industry chain, blue tungsten has evolved from a simple tungsten powder preparation raw material to a multifunctional material, which is widely used in photocatalysis, energy storage, electrochromic devices and gas sensors. With the rapid development of nanotechnology and green chemistry, the research and application of blue tungsten has shown unprecedented breadth and depth, and its potential is being jointly explored by academia and industry. It is based on this background that the expert team of CTIA GROUP wrote this book, aiming to provide scholars, R&D personnel and producers with a systematic, authoritative and practical reference guide.

Purpose and Readership

The primary goal of this book is to build a bridge for the relevant research and application of blue tungsten oxide, connecting academic theory with industrial practice. We hope to provide targeted support for readers from different backgrounds by deeply analyzing the properties, preparation processes and multi- field applications of blue tungsten. For academic researchers, this book provides a detailed analysis of the physical and chemical properties, detection methods and cutting-edge technological challenges of blue tungsten, supplemented by a wealth of references and standards to help deepen theoretical exploration and experimental design. For industry R&D personnel, this book systematically sorts out the production process optimization, application expansion direction and technical bottleneck solutions of blue tungsten, providing guidance for the development of new materials and performance improvement. For producers, this book introduces in detail the equipment selection, process parameters and environmental protection measures for industrial production, and is equipped with operational experimental plans and quality control standards to ensure a smooth transition from laboratory to factory. Whether it is a student who is first exposed to blue tungsten, an expert in the field of tungsten materials, or an engineer seeking technological breakthroughs, this book strives to become a must-have tool book on their desks.

The Importance of Blue Tungsten

The importance of blue tungsten oxide stems from its unique physical and chemical properties and broad application prospects. Its value is not only reflected in the scientific field, but also has a profound impact on industrial production, environmental protection, economic benefits and social development. As a non-stoichiometric compound between tungsten trioxide (WO₃ ) and tungsten dioxide (WO₂ ), blue tungsten has a narrow band gap (2.4-2.8 eV) and high conductivity due to the presence of oxygen defects, which makes it perform better than traditional tungsten oxide in visible light catalysis, electrochromic modulation and electrochemical energy storage.

Compared with fully oxidized WO₃, the oxygen vacancies of blue tungsten give it stronger light absorption ability and charge separation efficiency, which makes it have significant advantages in applications such as photocatalytic degradation of organic pollutants or photocatalytic water splitting to produce hydrogen. At the same time, its partially reduced structure enables it to achieve faster response speed and higher optical modulation rate in electrochromic devices, providing an ideal material for smart windows and display technologies.

In the industrial field, the importance of blue tungsten is particularly prominent. As a key intermediate for the production of ultrafine tungsten powder and cemented carbide, the preparation process of blue tungsten directly determines the particle size distribution, purity and performance of downstream products. For example, by precisely controlling the conditions of hydrogen reduction, blue tungsten can generate tungsten powder with a particle size of less than 1 micron, which is widely used in aerospace, electronic devices and cutting tool manufacturing. The global tungsten resource reserves are limited (China accounts for about 60%), and the efficient production process of blue tungsten can significantly improve the utilization rate of tungsten, reduce energy consumption (about 1-2 kWh/kg), and reduce waste liquid emissions in traditional hydrometallurgy. This high efficiency and sustainability make it an indispensable link in the tungsten industry chain. In addition, the production technology of blue tungsten has also promoted the development of tungsten-based catalysts , such as its application in ammonia synthesis and petrochemicals, reflecting its potential value in the field of industrial catalysis.

From the perspective of environmental benefits, the role of blue tungsten in green technology is becoming increasingly prominent. With the global emphasis on carbon neutrality goals, photocatalytic technology has become an important means to control environmental pollution and develop clean energy. With its visible light response characteristics, blue tungsten can efficiently degrade organic dyes in industrial wastewater (such as methylene blue, degradation rate > 95%), and exhibits excellent stability and hydrogen production efficiency in photolysis of water to produce hydrogen . This ability not only helps to reduce the emission of chemical pollutants, but also provides a new path for the development of renewable energy. In addition, the application of blue tungsten in electrochromic smart windows can significantly reduce building energy consumption (modulation rate > 80%), reduce the use of air conditioning by dynamically adjusting the indoor light and heat environment, and indirectly reduce carbon footprint. These environmental benefits make it one of the material science solutions to climate change.

Economic potential is another key manifestation of the importance of blue tungsten. The global tungsten market is expected to exceed US$5 billion in 2025, and as a high value-added material, the production and application of blue tungsten directly promote the upgrading of related industrial chains. Taking nano blue tungsten as an example, its excellent performance in supercapacitors (specific capacity>200 mAh /g) and lithium battery electrodes makes it an important part of the new energy industry. Compared with traditional materials, the high cycle stability and energy density of blue tungsten can significantly improve the life and efficiency of energy storage equipment, meeting the rapidly growing demand for electric vehicles and renewable energy storage. At the same time, the high sensitivity of blue tungsten in gas sensors (response rate>20%) gives it broad market prospects in the fields of industrial safety monitoring and medical diagnosis. These emerging applications not only enhance the economic value of blue tungsten, but also inject new impetus into the diversified development of the tungsten industry .

The social impact of blue tungsten cannot be ignored either. In the context of smart manufacturing and smart city construction, the versatility of blue tungsten provides support for technological innovation. For example, its application in electrochromic displays has promoted the development of flexible electronic devices and may give rise to a new generation of wearable devices and smart glass. In addition, the antibacterial properties of blue tungsten (derived from its photocatalytic activity) make it show potential in the field of medical materials, such as the development of antibacterial coatings or air purification materials. These applications directly improve the quality of life and health of human beings, reflecting the profound contribution of materials science to social progress.

The importance of blue tungsten also lies in its connection with the dual needs of basic research and industrial practice. At the academic level, the oxygen defect mechanism, morphology regulation and performance optimization of blue tungsten provide rich experimental models for solid-state chemistry, surface science and nanotechnology. For example, studying the formation and migration rules of its oxygen vacancies not only deepens the theory of oxide semiconductors, but also provides inspiration for the design of other non-stoichiometric materials (such as TiO ₂₋ₓ and MoO ₃₋ₓ ). At the industrial level, the optimization of blue tungsten production processes (such as tail gas recovery rate > 90%) and green preparation technology (such as recycling of waste tungsten) are the key to achieving sustainable development. Especially in the context of global resource shortages and increasing environmental pressures, the low-cost and high-efficiency production path of blue tungsten is becoming the focus of industry competition. Based on this dual value, this book strives to provide comprehensive support for the full life cycle research and application of blue tungsten.

Overview of the book structure

This book is divided into eight chapters and five appendices. The structure design follows the logical progression from foundation to application, from theory to practice. Chapter 1 “Introduction” reviews the history and current status of blue tungsten, laying a research background for readers. Chapter 2 “Basic properties of blue tungsten oxide” explores its chemical structure, photoelectric properties and stability in depth, providing a theoretical basis for subsequent chapters. Chapter 3 “Production process of blue tungsten oxide” introduces a variety of preparation methods such as hydrogen reduction, hydrothermal, supercritical and vapor deposition in detail, taking into account laboratory and industrial needs. Chapter 4 “Detection and characterization of blue tungsten oxide” systematically explains the chemical composition, phase composition and performance testing technology to guide precise analysis. Chapter 5 “Application fields of blue tungsten oxide” covers applications such as photocatalysis, energy storage, and electrochromism, showing its versatility. Chapter 6 “Industrial production and optimization” focuses on equipment design, quality control and energy efficiency improvement, providing a practical guide for producers. Chapter 7 “Technical challenges and future development” analyzes current bottlenecks and looks forward to emerging technologies and sustainable development directions. Chapter 8 “Conclusion and Prospect” summarizes the book and puts forward future suggestions.

To enhance practicality, the book’s appendix provides comprehensive supplements: Appendix A includes a multilingual glossary to facilitate international communication; Appendix B provides laboratory and industrial preparation plans with specific parameters; Appendix C lists relevant patents to facilitate technological innovation; Appendix D compares national standards to standardize quality control; Appendix E brings together 50 references, covering academic papers, patents, standards and books to ensure the authority of the source of knowledge.

Blue tungsten oxide is not only a branch of tungsten chemistry, but also a model of the integration of materials science and industrial technology. This book hopes to promote the dual breakthroughs of blue tungsten in academic research and industrial applications through systematic knowledge organization and practical guidance. We hope that readers can draw inspiration from it, whether it is to explore its microscopic mechanism, optimize its production process, or develop its new application, and jointly promote the future development of this material. Thanks to all the scholars, engineers and producers who have contributed their wisdom to this field. It is their efforts that have laid a solid foundation for this book.

Table of contents

Preface

The Importance of Blue Tungsten: The Unique Status and Multifunctionality of Non-Stoichiometric Tungsten Oxide

Book Structure Overview: Full Chain Coverage from Basics to Applications

Purpose and Readership: To Provide a Comprehensive Reference for Academic Research, Industrial R&D, and Production Practice

Chapter 1 Introduction

1.1 Discovery of Blue Tungsten

1.2 Classification of Non-Stoichiometric Tungsten Oxides (WO₃, WO₂.₉, WO₂.₇₂, WO₂)

1.3 The Status of Blue Tungsten in the Tungsten Industry Chain

1.4 Current Status and Trends of Research and Application

Chapter 2 Basic Properties of Blue Tungsten Oxide

2.1 Chemical Composition and Structure

2.1.1 Chemical Formula (WO₂.₉ or W₂₀O₅₈)

2.1.2 Crystal Structure and Oxygen Defects

2.2 Physical Properties

2.2.1 Color and Appearance (Blue Powder)

2.2.2 Density, Melting Point, and Thermal Stability

2.3 Optical and Electrical Properties

2.3.1 Bandgap Energy (2.4–2.8 eV)

2.3.2 Electrical Conductivity and Oxygen Vacancy Effect

2.4 Chemical Stability and Reactivity

2.4.1 Oxidation and Reduction Behavior

2.4.2 Stability Under Environmental Conditions

Chapter 3 Production Process of Blue Tungsten Oxide

3.1 Raw Material Selection and Pretreatment

3.1.1 Ammonium Paratungstate (APT)

3.1.2 Tungsten Acid and Tungsten Concentrate

3.2 Main Preparation Methods

3.2.1 Hydrogen Reduction Method

Process Parameters (Temperature 500–800°C, H₂ Flow Rate)

Equipment (Tube Furnace, Rotary Kiln)

3.2.2 Hydrothermal and Solvothermal Methods

Reaction Conditions (High Pressure, 180–250°C)

Nanostructure Control

3.2.3 Supercritical Fluid Method

Applications of Supercritical Alcohol

3.2.4 Vapor Deposition Method

Chemical Vapor Deposition (CVD) and Physical Vapor Deposition (PVD)

3.3 Process Optimization and Morphology Control

3.3.1 Nanoparticles, Nanorods, and Nanowires

3.3.2 Temperature, Atmosphere, and Catalyst Effects

3.4 Challenges of Industrial Production

3.4.1 Consistency and Productivity

3.4.2 Energy Consumption and Cost Control

Chapter 4 Detection and Characterization of Blue Tungsten Oxide

4.1 Chemical Composition Analysis

4.1.1 ICP-OES and ICP-MS (Impurity Detection)

4.1.2 Oxygen Content Determination

4.2 Phase Composition and Structure Analysis

4.2.1 X-Ray Diffraction (XRD)

4.2.2 Raman Spectroscopy and Infrared Spectroscopy

4.3 Morphology and Particle Size Analysis

4.3.1 Scanning Electron Microscope (SEM) and Transmission Electron Microscope (TEM)

4.3.2 Laser Particle Size Analysis

4.4 Performance Test

4.4.1 Photocatalytic Efficiency (Dye Degradation Rate)

4.4.2 Electrochromic Performance (Modulation Rate)

4.4.3 Electrochemical Performance (Specific Capacity, Cycle Stability)

Chapter 5 Application Fields of Blue Tungsten Oxide

5.1 Photocatalysis and Environmental Applications

5.1.1 Degradation of Organic Pollutants

5.1.2 Photocatalytic Hydrogen Production from Water

5.2 Electrochromic Devices

5.2.1 Smart Windows

5.2.2 Displays and Optical Modulation

5.3 Energy Storage Materials

5.3.1 Supercapacitor

5.3.2 Lithium-Ion Battery Electrodes

5.4 Gas Sensors

5.4.1 NO₂, CO, and Other Gas Detection

5.4.2 Sensitivity and Selectivity Optimization

5.5 Tungsten Powder and Cemented Carbide Production

5.5.1 Blue Tungsten as an Intermediate

5.5.2 Preparation of Ultrafine Tungsten Powder

Chapter 6 Industrial Production and Optimization

6.1 Industrial Equipment and Process Design

6.1.1 Rotary Kiln and Fluidized Bed

6.1.2 Continuous Production Process

6.2 Quality Control and Standards

6.2.1 Purity (>99.95%) and Impurities (Fe, Mo <10 ppm)

6.2.2 Particle Size Distribution and Morphology Consistency

6.3 Energy Efficiency and Environmental Protection Measures

6.3.1 Energy Consumption Optimization (1–2 kWh/kg)

6.3.2 Tail Gas Recovery (H₂O >90%)

6.4 Production Case Analysis

6.4.1 Small-Scale Test (10 kg/batch)

6.4.2 Large-Scale Production (1000 kg/batch)

Chapter 7 Technical Challenges and Future Development

7.1 Current Technical Bottlenecks

7.1.1 Precise Control of Morphology and Performance

7.1.2 Stability of Large-Scale Production

7.2 Emerging Preparation Technologies

7.2.1 Electrochemical Reduction Method

7.2.2 Plasma Enhanced Method

7.3 Application Development Direction

7.3.1 Flexible Electronic Devices

7.3.2 Biomedical Applications (Such as Antibacterial Materials)

7.4 Sustainable Development and Circular Economy

7.4.1 Recycling of Waste Tungsten to Produce Blue Tungsten

7.4.2 Green Production Path

Chapter 8 Conclusion and Outlook

8.1 Research and Application of Blue Tungsten

8.2 Directions for Future Research and Technological Breakthroughs

Appendix

Appendix: Glossary of Blue Tungsten Oxide Related Terms

Multi-Language References Include Chinese, English, Japanese, Korean, and German, Covering Production, Testing, and Application Terms (Such as “Hydrogen Reduction”, “Nanorods”, and “Photocatalytic Efficiency”)

Appendix: Experimental Protocol for Preparation of Blue Tungsten Oxide

Laboratory (5 g Scale, Tube Furnace) and Industrial (100 kg/batch, Rotary Kiln) Procedures with Parameters and Considerations

Appendix: List of Patents Related to Blue Tungsten Oxide

Patent Numbers, Titles, Abstracts, Covering Chinese, American, Japanese, Korean, European, and International Patents

Appendix: List of Blue Tungsten Oxide Standards

Comparison with Chinese, Japanese, German, Russian, Korean, and International Standards (Such as GB/T 4324-2012, ISO 10397:1993)

Appendix: Blue Tungsten Oxide References

Academic Papers (20), Patents (15), Standards (10), and Books (5), with Detailed Sources and Descriptions

Appendix: List of Equipment and Instruments Required for the Production of Blue Tungsten Oxide

READ MORE:Blue Tungsten Oxide Physical and Chemical Properties, Preparation and Applications

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

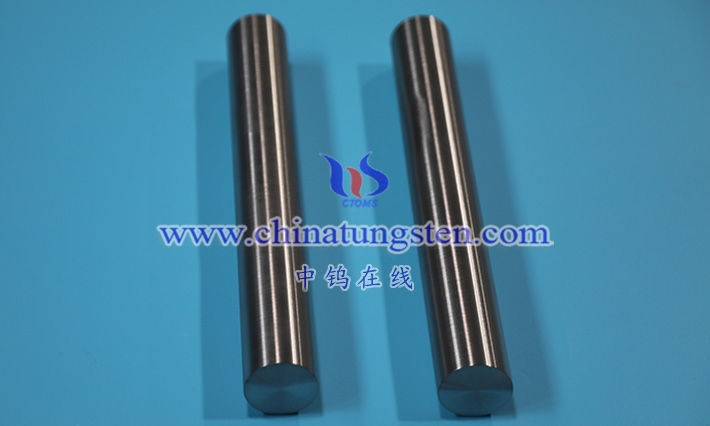

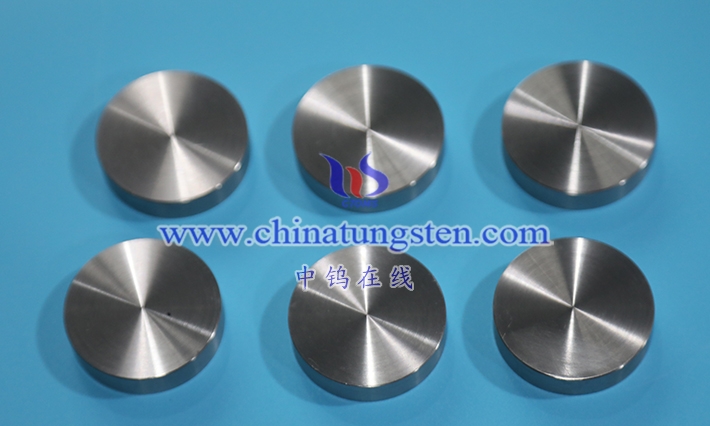

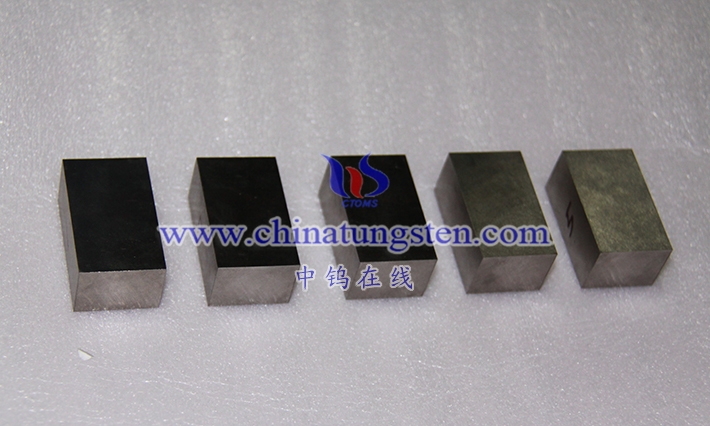

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

For more information about tungsten chemical products please visit the website: tungsten-powder.com

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595