Molybdenum crucible mainly includes the following, and the specific choice depends on the size, shape, performance requirements and application scenarios of the crucible. The following are common molding methods and their characteristics:

- Sintering

Process Description:

High-purity molybdenum powder (purity is usually ≥99.95%) is mixed with a small amount of binder, pressed into a crucible green body through a mold, and then sintered at high temperature (~1800-2200°C) in vacuum or hydrogen atmosphere.

Features:

Suitable for mass production with low cost.

The crucible has a slightly lower density (~90-95% theoretical density) and is slightly less mechanically strong and durable than a forged crucible.

The surface is rough and requires subsequent polishing or processing to improve the finish.

Applicable scenarios:

Industrial applications with low to medium precision requirements, such as general metal melting and sintering processes.

Production of large or complex shaped crucibles.

- Forging

Process Description:

from high-purity molybdenum billets (bars or plates) through mechanical processing such as forging, turning, milling, etc. It is usually forged at high temperature to increase the material density, and then finely machined into shape.

Features:

The crucible has high density (close to 100% theoretical density) and excellent mechanical strength and high temperature resistance.

High surface finish and dimensional accuracy, suitable for demanding processes.

The cost is high, the processing cycle is long, and there is a lot of material waste.

Applicable scenarios:

High-precision applications, such as semiconductor crystal growth (sapphire, single crystal silicon), precious metal melting.

Small to medium sized crucibles requiring high strength and corrosion resistance.

- Spinning

Process Description:

Molybdenum sheets or flakes are placed on a spinning machine, which shapes the molybdenum sheet into a crucible shape by rotating dies and tools, usually at high temperatures to improve ductility.

Features:

The wall thickness is uniform, suitable for producing thin-wall crucibles.

The cost is moderate and the production efficiency is high, but the size and shape are limited by the mold.

The strength and density are slightly lower than those of forged crucibles, but better than those of sintered crucibles.

Applicable scenarios:

Small to medium sized cylindrical or conical crucibles suitable for laboratory or industrial heat treatment.

A process with high requirements on wall thickness uniformity.

- Welding

Process Description:

Molybdenum plates or sheets are cut into the required shape and assembled into crucibles by welding (usually tungsten inert gas welding or electron beam welding). Welding is usually carried out under vacuum or inert atmosphere to avoid oxidation.

Features:

Suitable for producing large or complex shaped crucibles with high flexibility.

Welds may become weak points at high temperatures and require high-quality welding technology.

The cost is high and additional testing of weld quality is required.

Applicable scenarios:

Large crucibles or crucibles of non-standard shapes are used in metallurgy or special industrial processes.

Scenarios that require flexibility in size but high weld performance.

- Isostatic pressing (cold isostatic pressing or hot isostatic pressing)

Process Description:

Molybdenum powder is loaded into a flexible mold and formed by cold isostatic pressing (CIP) or hot isostatic pressing (HIP) equipment with uniform high pressure, followed by sintering or further processing. Hot isostatic pressing can directly increase density under high temperature and pressure.

Features:

The crucible has high density, close to the theoretical value, and its performance is close to that of a forged crucible.

Suitable for complex shapes and high-quality crucibles, but the equipment and process costs are high.

The production cycle is long and the process parameters need to be precisely controlled.

Applicable scenarios:

High-end applications such as aerospace, semiconductors or high-precision scientific research experiments.

Crucibles with high density and uniformity are required.

- Other special molding methods

Chemical vapor deposition (CVD) or deposition modeling (less common):

molybdenum layer on the mold by CVD, which is suitable for ultra-thin or special structure crucibles.

Features: high purity, ultra-thin wall, but extremely high cost and low yield.

Application: Special scientific research or micro crucible.

3D Printing (Emerging Technology):

The crucible prototype is printed using molybdenum powder through additive manufacturing techniques such as selective laser melting (SLM), and then sintered or processed.

Features: suitable for complex shapes, the technology is not yet mature, and the cost is high.

Usage: Custom or experimental applications.

- Comparison of molding methods

| Forming method | density | strength | cost | Applicable scenarios | limitation |

| Sintering | Moderate (90-95%) | medium | Lower | General industry, mass production | Low strength, rough surface |

| Forging | High (~100%) | high | high | High precision, semiconductor, precious metal melting | Complex processing, waste of materials |

| Spinning | Medium to high | Medium to high | medium | Small and medium thin wall crucible | Size limited, mold dependent |

| Welding Forming | Medium to high | Medium (weak weld) | high | Large or complex shape crucibles | Limited high temperature performance of welds |

| Isostatic Pressing | High (~100%) | high | Very high | High-end applications, aerospace | Expensive equipment and long cycle |

======================================================================

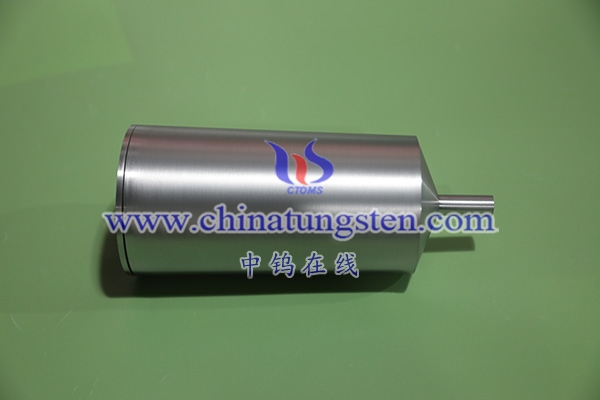

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595