Molybdenum crucibles can be machined, but due to the high melting point, high hardness, low plasticity and high brittleness of molybdenum, its machining process requires special attention to cutting conditions, tool selection and cooling methods. Reasonable processing technology can ensure the dimensional accuracy and surface quality of the crucible and avoid cracking or breaking.

- molybdenum:

| characteristic | describe |

| High melting point | 2623 ° C, it will not melt during processing, but the heat affected zone will change its structure |

| High hardness | The tool wear is large, so you need to choose a tool made of high hardness material |

| Very brittle | Prone to micro cracks or edge collapse due to mechanical impact |

| Good thermal conductivity | Heat is quickly conducted, and the local temperature rise is small during processing, but it is easy to deform. |

| Small work hardening | Suitable for turning and milling, but prone to cracking after deformation during processing |

- Common machining processes for molybdenum crucibles:

| Processing method | illustrate | Recommended Uses |

| Turning | Mainly used for appearance finishing and bottom processing | Making the outer wall and bottom of cylindrical crucible |

| Milling | Can be used to cut complex planes or grooves | Flange crucible edge or interface |

| drilling | Make air holes, temperature probe ports, bracket holes, etc. | Special purpose crucible |

| Planing/grinding | Used for end surface finishing when high precision is required | High-precision crucible cover or connection parts |

| Wire cutting | Fine grooves or complex geometries | Mould crucible or connection structure |

| Electrical Discharge Machining (EDM) | For micromachining of thin-walled structures or small features | Special crucibles or test models |

- Precautions for Molybdenum Processing

Tool material: It is recommended to use carbide (such as YG8, PVD coated tools)** or diamond tools;

Cutting speed: should be low (20–40 is recommended for turning m/min) to prevent chipping or burning of the knife;

Feed rate/depth: Small feed and small knife are suitable (0.05–0.2 mm/rev), avoid severe load;

Cooling and lubrication: It is recommended to use emulsion or oil mist cooling to prevent heating and tool wear;

Clamping method: Avoid strong clamping, and it is recommended to use flexible claws or wrapped clamps;

Post-processing: Annealing or polishing is often performed after processing to eliminate residual stress and improve surface quality.

- Common machine tools suitable for processing molybdenum crucibles

Precision CNC lathe (CNC)

Horizontal milling machine (with slow speed function)

Electric discharge machine (EDM)

Internal grinding machine (for high-precision sealing parts)

======================================================================

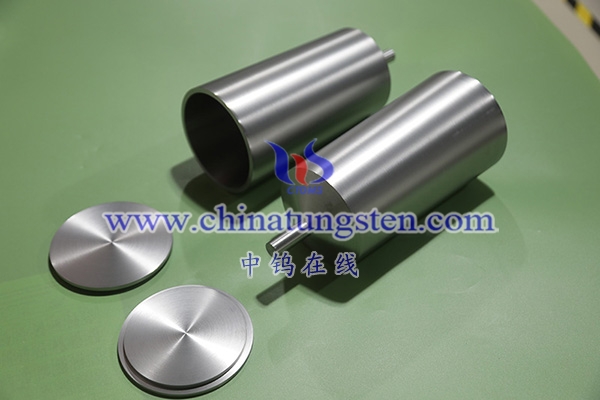

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595