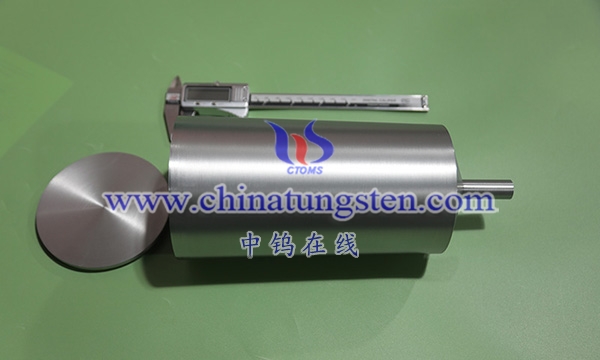

Molybdenum crucible can be made into lidded structure and is widely used in high temperature experiments, crystal growth, semiconductor manufacturing and other fields. The following is a detailed description:

- Feasibility of molybdenum crucible with cover

Material properties support

Molybdenum (Mo) has a melting point of up to 2623°C and has excellent high-temperature strength, making it suitable for making sealing structures.

The cover and the crucible can be connected by welding, riveting or screwing to ensure sealing.

- Design points of molybdenum crucible with cover

| Design elements | Key points |

|–||

| Connection method| – Welding: Electron beam welding (EBW) or laser welding, suitable for high temperature sealing.

– Thread: Precision turned thread, requires sealing ring (such as graphite, zirconium oxide).

– Riveting: suitable for low temperature or non-vacuum environment. |

| Sealing structure | – Plane seal: The cover is flush with the crucible mouth and requires high-precision processing (Ra0.4 μm).

-Boss seal: The cover is designed with a boss that is inserted into the crucible mouth to enhance sealing. |

| Exhaust hole| – A tiny exhaust hole (0.1-0.5 mm in diameter) needs to be designed to prevent excessive pressure during heating. |

| Material Matching| – The cover and crucible must be made of the same material (pure molybdenum or molybdenum alloy) to avoid cracking due to differences in thermal expansion coefficients. |

- Application scenarios of molybdenum crucible with cover

Crystal Growth

Requirements: Sealed environment to prevent contamination by impurities and controlled atmosphere (such as vacuum, inert gas).

Typical structure: diameter 100-300 mm, height 150-400 mm, with threaded cover.

Semiconductor Manufacturing

Requirements: High vacuum environment (≤10^-6 Pa), electron beam welding sealing is required.

Typical structure: diameter 50-100 mm, height 50-150 mm, with flat sealing cover.

High temperature experiment

Requirements: Quick opening and closing for easy sampling.

Typical structure: diameter 20-50 mm, height 30-80 mm, with riveted cover.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595