In the production of molybdenum crucible, oxygen content is a key factor affecting material properties (such as ductility and corrosion resistance). Controlling oxygen content requires starting from multiple links such as raw materials, processes, and equipment. The following are specific control methods:

- Raw material control

Select high purity molybdenum powder

Standard: Oxygen content ≤ 0.01wt % (such as Mo-1 grade molybdenum powder).

Measures: Prioritize the purchase of molybdenum powder produced by gas atomization or plasma rotating electrode method, which has lower oxygen content and uniform particle size.

Avoid raw material contamination

Storage: Molybdenum powder needs to be stored in a vacuum or inert gas (such as argon) environment.

Mixing: Use vacuum mixing equipment to prevent contact with air.

- Process Optimization

Sintering process

Vacuum sintering: Sintering at 1800-2200℃ and vacuum degree ≤1×10 ⁻³ Pa can effectively remove oxygen.

Hydrogen protection sintering: Sintering in a hydrogen atmosphere, hydrogen reacts with oxygen to generate water vapor and is discharged, and the oxygen content can be reduced to ≤ 0.005wt %.

Isostatic Pressing

Cold Isostatic Pressing (CIP): Pressurization in an inert gas environment to avoid oxidation.

Hot Isostatic Pressing (HIP): High temperature and high-pressure act simultaneously to further densify and reduce oxygen content.

Machining

Cutting fluid selection: Use cutting fluid containing extreme pressure additives to reduce oxidation caused by high temperature during processing.

Tool material: Use carbide or diamond tools to reduce friction heat.

- Equipment and Operation Control

Sintering equipment

Vacuum furnace: Check the sealing of the furnace body regularly to ensure that the vacuum degree meets the standard.

Hydrogen furnace: Control the hydrogen flow rate (e.g. 5-10 L/min) to ensure a reducing atmosphere.

Operation Specifications

Loading: Load and seal quickly to reduce contact time with air.

Heating rate: Control the heating rate (e.g. ≤5°C/min) to avoid local overheating and oxidation.

- Detection and Monitoring

Oxygen content detection

Method: The inert gas melting infrared absorption method is used, and the detection accuracy can reach 0.0001wt %.

Frequency: Each batch of raw materials and finished products needs to be tested.

Process Monitoring

Install oxygen sensors to monitor the oxygen content in the furnace in real time and adjust process parameters in time.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

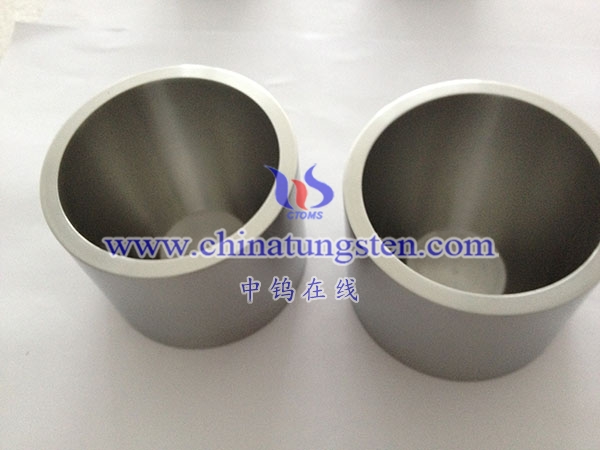

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595