Molybdenum crucibles can be manufactured entirely by powder metallurgy, which is a very common and efficient method in industrial production, especially suitable for manufacturing high-purity, large-size or special-structured molybdenum crucibles. Compared with traditional melting or forging processes, powder metallurgy has unique advantages, but it also has certain technical challenges.

- The basic process of powder metallurgy to manufacture molybdenum crucible:

Molybdenum powder preparation

High purity molybdenum powder is obtained by reduction method (such as molybdenum oxide hydrogen reduction).

The particle size is usually controlled at 1~5 μm and can be adjusted according to application needs.

Forming

The molybdenum powder is pressed into a blank body similar to the shape of a crucible by cold isostatic pressing (CIP) or mold pressing.

The pressure is generally 150–300 MPa, forming a preformed block with good density.

sintering

High temperature sintering (usually at 1800–2100 °C) is performed in vacuum or hydrogen atmosphere. ° C).

Sintering time depends on size and density requirements and is generally 2–5 hours.

molybdenum blank with certain strength and density is formed , and the density can reach more than 98%.

Post-processing (optional)

Machining: finishing the internal and external shapes and dimensions, removing sintering defects;

Annealing treatment: eliminate residual stress;

Welding/Assembly: For crucibles of large size or composite structure.

- Advantages of powder metallurgy molybdenum crucible:

High purity and strong control capability

The raw material powder can precisely control the impurity elements and is suitable for fields such as semiconductors and crystal growth that have extremely high purity requirements.

Can form complex structures

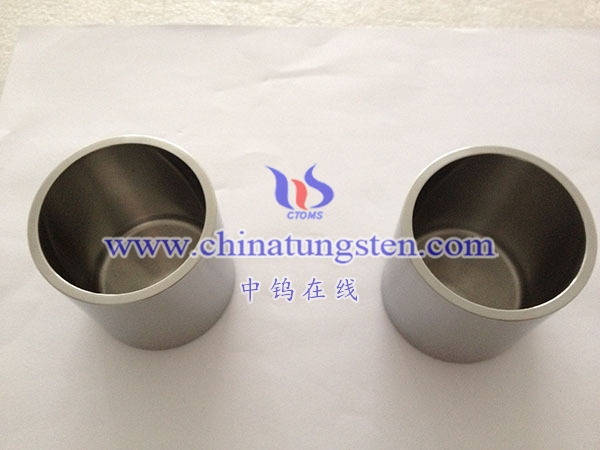

Such as thickened bottom, thin-walled cylinder, special-shaped crucible, etc., with high flexibility.

More controllable costs

It is especially suitable for batch production of small and medium-sized molybdenum crucibles, with high material utilization rate and saving of raw materials.

Uniform tissue structure

The grains inside the sintered body are fine, which is suitable for scenarios that require high temperature resistance and thermal shock resistance.

- Challenges or limitations:

Density is slightly lower than wrought molybdenum (but can be improved by secondary hot isostatic pressing or heat treatment);

The larger the size, the more difficult it is to control the sintering deformation, and warping or uneven shrinkage is more likely to occur;

After sintering, machining is still required to adjust the size and surface, especially for precision applications;

The sintering process has high requirements on furnace body and atmosphere control, otherwise it is easy to introduce impurities or cause loose structure.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595