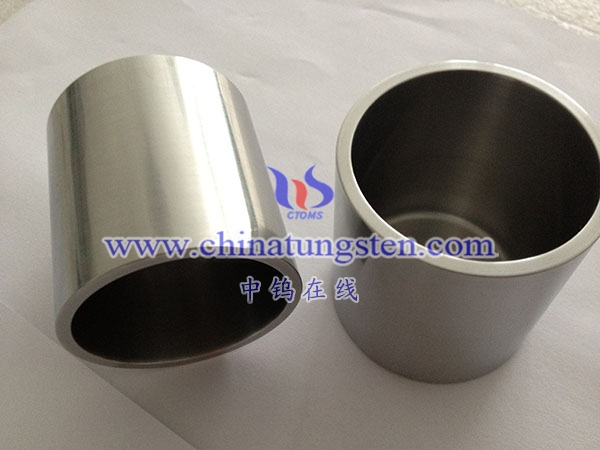

Molybdenum crucibles can be finely processed using CNC machine tools, and have significant advantages in high-end applications. The following is a detailed description of technical feasibility, process points, application cases and precautions:

- Technical feasibility

Material property adaptation

molybdenum has high hardness (HV200-300) and melting point (2620℃), CNC can achieve stable processing by properly selecting tools and parameters.

Ductility: Molybdenum’s ductility increases at high temperatures, which reduces the risk of machining cracks.

Processing accuracy

CNC can achieve a dimensional accuracy of ± 0.01mm, meeting the high-precision requirements of sapphire single crystal growth furnaces.

Ra0.4 μm or less can be achieved by optimizing cutting parameters.

- Key process parameters

| parameter | Recommended value | illustrate |

| Tool material | Carbide (such as K10 / K20 ) or CBN | Avoid high temperature softening to ensure cutting edge life |

| Cutting speed | 20-50 m/min | High-speed cutting can reduce cutting forces and deformation |

| Feed | 0.05-0.2 mm/rev | Small feed rate reduces surface roughness |

| Cutting depth | 0.1-0.5 mm | Avoid excessive cutting force causing cracks |

| Cooling method | Emulsion or oil-based cutting fluid | Prevent high temperature oxidation and lubricate the cutting area |

- Comparison with traditional technology

| index | CNC machining | Traditional machining (such as lathe/milling machine) |

| Dimensional accuracy | ± 0.01mm | ± 0.05mm |

| Surface roughness | Ra0.4 μm | Ra1.6 μm |

| Processing efficiency | Medium (limited by tool life) | high |

| applicability | Complex shapes and high precision requirements | Simple shape, low precision requirements |

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595