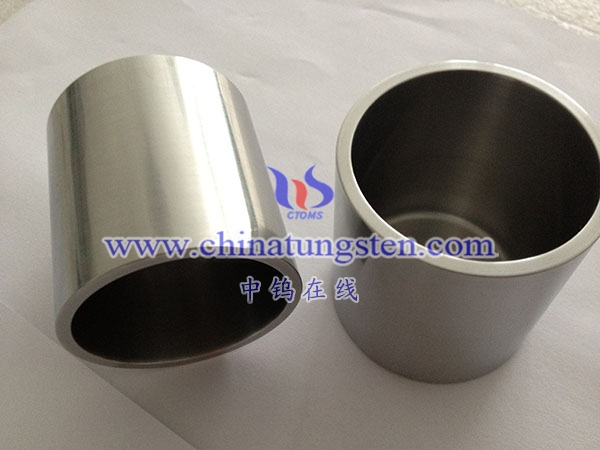

Molybdenum crucibles usually need to undergo heat treatment (especially annealing) to enhance their performance, which is an important link that cannot be ignored in the processing of molybdenum products. Through heat treatment, the organizational structure, mechanical properties, thermal stability and crack resistance of molybdenum crucibles can be significantly improved, thereby extending their service life in high-temperature applications.

- Why does the molybdenum crucible need heat treatment?

- Release machining residual stress

Molybdenum materials will generate a large amount of residual internal stress during forging, spinning, welding, machining and other processes. If they are not heat treated, they may deform or even crack under high temperature thermal shock during use.

- Improve grain structure and toughness

Heat treatment can make the molybdenum grains more uniform and refined, reduce the cold brittleness of the material, and improve its impact resistance under thermal cycling conditions.

- Enhanced high temperature oxidation resistance and creep resistance

Appropriate high-temperature heat treatment can optimize the oxide film structure on the molybdenum surface, form a denser molybdenum oxide layer during use, and improve its thermal stability.

- Common heat treatment methods

High temperature annealing (commonly used)

Temperature range: 1100–1400 ° C

Atmosphere requirements: high vacuum or pure hydrogen environment

Function: Mainly used to eliminate stress, soften materials, and improve tissue

Application stage: usually arranged after machining or welding, or after sintering and before finishing.

High temperature recrystallization annealing (for grain improvement)

Temperature range: 1600–1900 ° C

Atmosphere requirements: vacuum or hydrogen

Function: Used to refine coarse grains and improve high-temperature plasticity; often used for pretreatment of molybdenum plates and billets before forming.

Local heat treatment (for welding or special structures)

Used in welding joints to prevent cracks in the heat-affected zone;

Resistance heating or high frequency heating can be used for local treatment, sometimes supplemented by molybdenum heat sleeves or shielding.

- Performance improvement after heat treatment

| Performance | Before heat treatment | After heat treatment |

| internal stress | High, easy to deform | Low, stable structure |

| toughness | Poor, easy to crack | Significantly improved |

| Thermal shock resistance | medium | Significantly enhanced |

| Microstructure | Coarse/uneven grains | Grain refinement/uniformity |

| Dimensional stability | It is easy to shrink or warp when used at high temperature | More stable |

Especially for molybdenum crucibles used in high temperature and high stress environments such as single crystal growth furnaces, hot isostatic pressing furnaces, and rare earth smelting furnaces, heat treatment is a key process to ensure their performance and life.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595