In the process of molybdenum crucible welding, it is very important to choose the right filling material, because the filling material not only needs to have similar physical and chemical properties to molybdenum, but also needs to meet the requirements of high temperature, oxidation resistance, mechanical strength, etc. The following are commonly used molybdenum crucible welding filling materials and their characteristics:

- Common molybdenum crucible welding filling materials

- Molybdenum filling material

Applicable situations: When the welding requirements of molybdenum crucible are high, the most commonly used filler material is molybdenum, which is the same as the base material . This ensures that the chemical composition and physical properties of the welded joint are consistent with those of the base material.

Features:

It has excellent thermal stability and can adapt to high temperature environment;

It has good strength and plasticity, which can ensure the reliability of welding joints;

Mainly used for high temperature welding of molybdenum-based materials, such as welding of molybdenum crucibles.

- Tungsten filling material

Applicable situations: Molybdenum and tungsten have similar high melting points and high temperature oxidation resistance, so tungsten filling materials can be used as welding fillers for molybdenum crucibles, especially in situations where high temperature strength and corrosion resistance are required.

Features:

Its high melting point (tungsten melts at about 3422°C) makes it stable even at extremely high temperatures;

Tungsten has similar chemical properties to molybdenum and is suitable for welding molybdenum crucibles.

- Molybdenum -Tungsten Alloy filling material

Applicable situations: Molybdenum -tungsten alloy filler materials are suitable for high temperature environments, especially in welding applications that require improved temperature resistance and mechanical strength.

Features:

Better high temperature resistance and oxidation resistance;

Can improve the strength and toughness of welded joints;

Suitable for thermal cycle applications with high requirements.

- Molybdenum-Chromium alloy filling material

Applicable situations: In some special high-temperature applications, molybdenum-chromium alloy filler materials can provide better oxidation resistance than pure molybdenum or tungsten, and are suitable for high-temperature working conditions with oxidizing environments.

Features:

Improved oxidation resistance by adding chromium;

Maintain strong structural stability in high temperature environment.

- Matching welding method and filling material

molybdenum crucibles:

Gas tungsten arc welding (TIG welding):

Commonly used for high temperature welding of molybdenum and molybdenum alloys, it can provide fine weld joints and low heat affected zones;

Molybdenum or molybdenum- tungsten alloy can be used as filler material to ensure chemical compatibility of the weld and the base material.

Laser welding:

Used for high-precision and high-strength welding, especially for welding thin-walled molybdenum crucibles;

Metals such as molybdenum and tungsten can be used as fillers during laser welding.

Electron beam welding:

Suitable for precision welding of molybdenum crucibles, especially under high vacuum conditions;

In the electron beam welding process, molybdenum, tungsten and molybdenum- tungsten alloys are often used as filler materials.

- Precautions during welding

Welding environment: Molybdenum and tungsten are highly sensitive to oxygen, so welding needs to be carried out in a vacuum or a protective atmosphere (such as hydrogen, argon) to avoid the formation of oxides.

Welding temperature: Ensure that the temperature is properly controlled during welding to avoid excessively high temperatures that may cause deterioration of the base material or filler material.

Treatment of welded joints: Appropriate annealing treatment should be carried out after welding to eliminate residual stress and improve the strength and stability of the joints.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

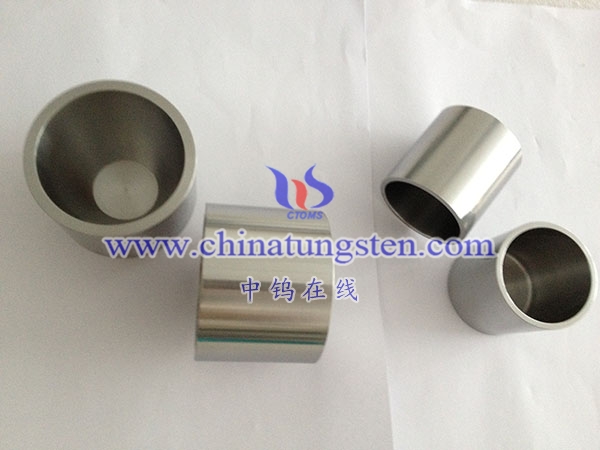

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595