Using molybdenum crucible on product purity mainly depends on its chemical stability, high temperature performance and processing technology. The following is a detailed analysis:

- The positive influence of molybdenum crucible on product purity

Chemical inertness

Does not react with most materials at high temperatures: Molybdenum does not react chemically with metals such as silicon, germanium, iron, nickel and their oxides below 1600°C, avoiding the introduction of impurities.

Low Solubility: The solubility of molybdenum in molten silicon is extremely low (<1 ppm), significantly reducing the risk of contamination.

Application scenarios:

Single crystal silicon growth: Molybdenum crucibles can maintain the purity of silicon and avoid impurity doping in the Czochralski method.

Rare earth metal smelting: In the preparation of rare earth permanent magnet materials such as NdFeB, molybdenum crucible can prevent the oxidation or volatilization of rare earth elements.

High temperature resistance

High melting point (2610℃): Molybdenum crucible can work stably above 2000℃, meeting the needs of smelting high-purity materials (such as the melting point of silicon is 1414℃).

Thermal shock resistance: Low thermal expansion coefficient (5.5×10 ⁻⁶ / ℃ ) reduces cracking caused by thermal stress and avoids the mixing of impurities.

High purity molybdenum material

Purity ≥99.95%: High-purity molybdenum crucibles have extremely low impurity content, further reducing the risk of contamination.

- Potential risks of molybdenum crucible to product purity

Oxidation Problem

High temperature oxidation: In air or oxygen environment, molybdenum is easily oxidized to form volatile MoO₃ (boiling point about 1155°C), resulting in material loss and introduction of impurities.

Solution:

Vacuum or inert gas protection: Use in vacuum or argon (Ar) atmosphere to avoid oxidation.

Surface coating: Use Mo₂C, ZrO₂ and other coatings to delay oxidation.

Processing pollution

Machining residue: Metal particles or lubricants may remain during the machining of the molybdenum crucible, which need to be removed by precision machining and cleaning.

Surface roughness: Surface defects may absorb impurities, so the surface finish must be ensured (Ra≤0.8 μm).

Impurity Diffusion

Molybdenum crucibles may slowly release trace impurities at high temperatures and need to be inspected and replaced regularly.

- Purity performance in different application scenarios

| Application Scenario | Purity Impact | Typical Cases |

| Single crystal silicon growth | Positive: Maintain high purity of silicon (> 9N) | Molybdenum crucible replaces quartz crucible in Czochralski single crystal silicon growth furnace |

| Rare earth metal smelting | Active: Prevent rare earth oxidation and volatilization | Preparation of NdFeB Permanent Magnet Materials |

| High temperature alloy melting | Neutral: need to pay attention to impurity diffusion | Nickel-based high-temperature alloy melting |

| Glass melting | Negative: Glass components may corrode molybdenum crucibles | Borosilicate glass melting (avoid using molybdenum crucibles) |

- Key measures to improve purity

Choose high-purity molybdenum material: ensure Mo ≥ 99.95% and reduce its own impurities.

Optimize processing technology: use precision processing technology (such as spinning and sintering) to control surface roughness.

Strict cleaning process: Use ultrasonic cleaning and high temperature degreasing to remove processing residues.

Environmental control: Use under vacuum or inert gas protection to avoid oxidation.

Regular inspection and replacement: Detect impurity content through ICP -MS and other means, and replace aging crucibles in time.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

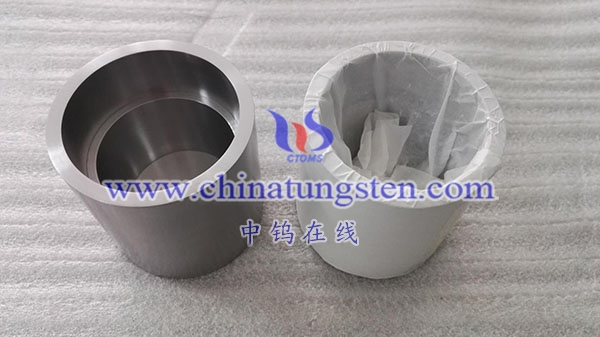

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595