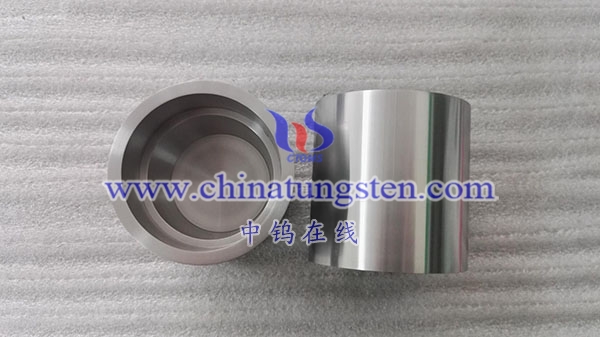

Molybdenum crucibles can be used with platinum metal under certain conditions, but they need to be used with great caution and depend on the use environment (especially temperature and atmosphere). Let’s analyze its compatibility and precautions in detail below:

- Shared Situations

- Use in vacuum or inert gas (such as argon)

In a high-temperature vacuum environment or in an inert atmosphere such as high-purity argon or helium, molybdenum and platinum will not undergo a violent chemical reaction. At this time, platinum metal can be melted or heated in a molybdenum crucible. For example:

platinum metal in a vacuum;

Use molybdenum crucibles to hold platinum alloys for electron beam melting or vacuum melting processes;

Powders for high temperature sintering of platinum-containing materials.

Molybdenum has a higher melting point (3410°C), while the melting point of platinum is 1768°C. The molybdenum crucible can stably load and heat the platinum material.

- Risks and precautions

Although the physical properties are well matched, chemical compatibility still needs attention:

Molybdenum and platinum may form intermetallic compounds at high temperatures

At temperatures above 1200–1400°C, solid solution reaction or formation of intermetallic compounds (e.g. Mo-Pt alloy layers) may occur between Mo and Pt if there is a long contact time and an active interface, especially in the following situations:

High temperature and long-term heat treatment;

Direct metal contact without buffer layer;

The presence of impurities (such as oxygen and sulfur) intensifies the reaction.

This results in:

Platinum metal is contaminated;

The inner wall of the molybdenum crucible is corroded and its life is shortened.

Therefore, for long-term high-temperature contact, direct metal contact should be avoided as much as possible.

- Do not use simultaneously in an oxidizing atmosphere

Molybdenum is very susceptible to oxidation at high temperatures (>400°C, where significant oxidation begins), while platinum exhibits good oxidation resistance. If used in air or an oxygen-containing atmosphere:

Molybdenum will quickly oxidize to form MoO₃ and sublime;

The vapors produced at the same time may contaminate the platinum material;

There is a risk of loss of control and possible damage to the equipment.

Therefore, when molybdenum crucible is used together with platinum, the atmosphere must be strictly controlled to be vacuum or high-purity inert gas.

- Solutions in actual industry

In order to achieve stable sharing of the two, the following methods are often used in industry:

Use an inert barrier

Add a ceramic film (such as aluminum oxide, boron nitride) between platinum and molybdenum as an isolation layer to avoid direct metal contact.

Low temperature short time heat treatment process

Control the temperature of the platinum treatment process to <1200°C and shorten the holding time to reduce the risk of diffusion reactions.

Select nested structure

A ceramic crucible is used to hold platinum, and the ceramic crucible is then nested in a molybdenum crucible to achieve indirect heating.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595