Molybdenum crucible plays an extremely critical role in the thermal field system. It is not only a high-temperature container, but also one of the core components of the thermal field system design and performance control. Especially in heat treatment systems such as single crystal growth, sapphire crystal growth, rare metal purification, and precision ceramic sintering, the molybdenum crucible is not only a part of the heat source structure, but also participates in the entire thermal distribution, heat conduction and temperature balance control.

- The core role of molybdenum crucible in thermal field system

- Primary Crucible

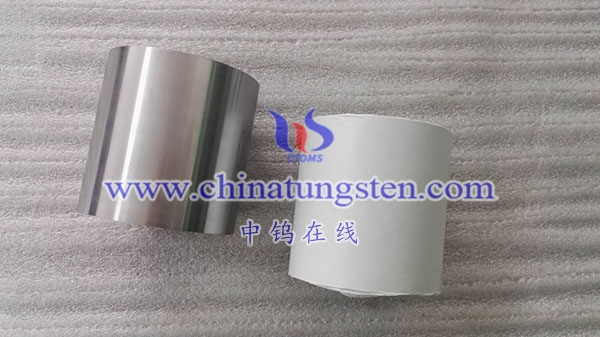

Molybdenum crucible is the main container for loading raw materials and melting or sintering in high temperature thermal field. Its high melting point (3410℃), stability and thermal shock resistance ensure that it will not deform or react in the thermal field for a long time.

- Heat conductor near the heat source

Due to the high thermal conductivity of molybdenum (about 138 W/m·K), it can quickly and evenly transfer the heat energy generated by external heating devices (such as resistance furnaces, induction coils, electron beams) to the raw material area, making the melt temperature field more balanced.

- An important part of temperature gradient control

Temperature gradient control is crucial in single crystal growth or directional solidification processes. The geometry, wall thickness, and coupling mode of the molybdenum crucible with the insulation layer directly affect the thermal field structure and thus the crystal quality (such as defect rate and dislocation density).

- Typical roles in thermal field systems

Molybdenum crucibles generally do not exist alone, but work together with other thermal field components:

| Thermal field components | with molybdenum crucible |

| Heater (resistance or induction) | The molybdenum crucible is close to the heat source and acts as a direct receiver of heat energy. |

| Reflective screen (molybdenum or tantalum) | with the molybdenum crucible, it creates a thermal enclosure to improve thermal efficiency and reduce heat loss. |

| Insulation layer (graphite felt, alumina felt) | Wrap the outer surface of the molybdenum crucible to limit heat diffusion and help maintain the high temperature core area |

| Support structure (molybdenum bracket or graphite table) | The molybdenum crucible is placed in the bracket to keep the structure stable and avoid deformation |

| Observation window and thermocouple system | the molybdenum crucible provides a melt environment for temperature sampling and image monitoring |

- The influence of molybdenum crucible material on thermal field system

Material purity

High purity molybdenum (>99.95%) has higher creep resistance and anti-pollution ability, which is particularly important for high-precision crystal growth.

Processing method

Different manufacturing processes (forging, spinning, welding, powder metallurgy) will affect the crucible’s thermal field symmetry, thermal stress response, residual stress distribution, etc., and indirectly affect the crystal growth quality.

Dimensional accuracy

The molybdenum crucible (such as coaxiality and wall thickness uniformity) will directly affect the thermal convection flow pattern and solidification interface morphology.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595