Molybdenum crucible plays a key role in the metal evaporation process. Its excellent high temperature resistance, chemical stability and mechanical properties make it a core tool in the metal evaporation process. The following is a specific analysis:

- Material properties of molybdenum crucible

High temperature resistance

molybdenum is as high as 2610℃, and it can work stably in a high temperature environment above 2000℃, meeting the high temperature environment requirements of the metal evaporation process.

Chemical stability

Molybdenum crucibles are not easy to react chemically with metals at high temperatures, which can effectively avoid impurity contamination and ensure the purity of the evaporated metal.

Mechanical properties

Molybdenum crucible has high strength and creep resistance, and the thin-wall design can withstand thermal stress at high temperatures and extend its service life.

- Application of molybdenum crucible in metal evaporation process

Evaporation source

The molybdenum crucible is used as an evaporation source. The metal is melted and evaporated through resistance heating or electron beam bombardment to form vapor atoms or molecules, which are deposited on the surface of the substrate to form a thin film.

Thin film preparation

In vacuum coating and evaporation coating processes, molybdenum crucibles are used to evaporate metals (such as aluminum, copper, gold, etc.) and compounds to prepare high-purity, uniform thin films, which are widely used in electronics, optics, aviation and other fields.

High temperature alloy preparation

When preparing high-temperature alloys, molybdenum crucibles can withstand high-temperature melting environments, ensure uniform alloy composition, and improve material properties.

- Process advantages of molybdenum crucible

High purity evaporation

the molybdenum crucible prevents contamination during metal evaporation, ensuring the purity and performance of the film.

Efficient evaporation

molybdenum crucibles can achieve fast and uniform metal evaporation and improve production efficiency.

Long life

molybdenum crucible make it have a long service life in high temperature environment and reduce production costs.

- Application Cases

Electronics Industry

In semiconductor manufacturing, molybdenum crucibles are used to evaporate high-purity metals and prepare conductive films and reflective layers.

Optical coating

In the manufacture of optical lenses and filters, molybdenum crucibles are used to evaporate multi-layer dielectric films to improve optical performance.

Aerospace

In the thermal protection systems of aircraft engines and spacecraft, molybdenum crucibles are used to prepare high-temperature resistant ceramic coatings and metal-based composite materials.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

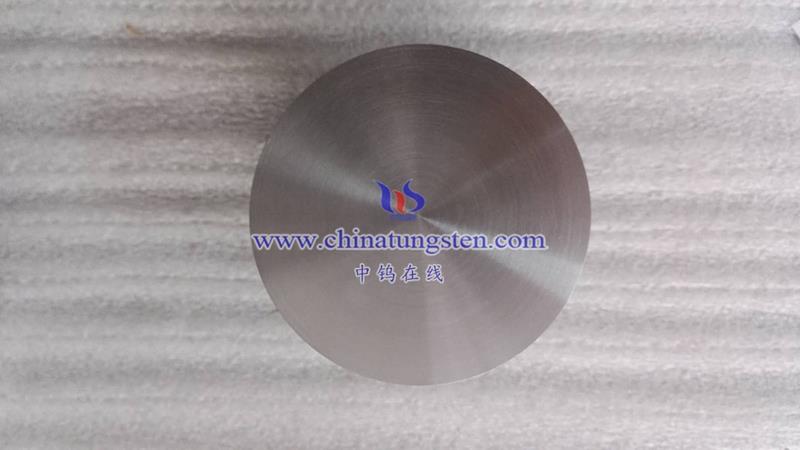

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595