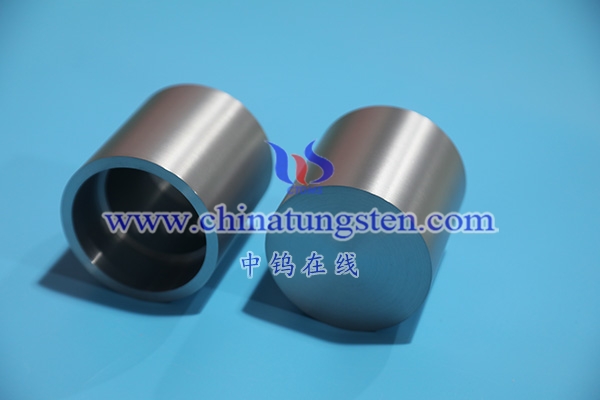

Molybdenum crucible usually needs to be preheated before use, which helps to avoid thermal stress cracking or cracks caused by sudden temperature rise. The preheating process can help the molybdenum crucible gradually adapt to the high temperature environment, thereby extending its service life and maintaining its structural integrity.

Necessity and steps of preheating:

Avoid thermal shock

Molybdenum crucible material has good thermal shock resistance at high temperatures, but if a cold crucible is placed directly in a high temperature environment, excessive thermal stress will be generated due to the rapid temperature change, causing the crucible to crack or break.

Preheating can gradually increase the crucible temperature and avoid damage caused by uneven thermal expansion.

Gradually heating up

It is recommended to adopt a gradual heating strategy, for example: 5–10°C per minute, especially for the first use or after annealing, to ensure that the temperature of the molybdenum crucible gradually approaches the working temperature.

The preheating temperature range is generally from room temperature to 500°C, gradually transitioning to the temperature required for the experiment.

Suitable for different experimental environments

If used in an inert atmosphere such as vacuum or argon, preheating can effectively reduce the moisture or oxidation effects of the gas and prevent the inner wall of the crucible from being corroded by oxides or water vapor.

If you are performing metal melting or crystal growth experiments, preheating allows the crucible to more evenly bear the heat load of the molten metal and avoid cracks caused by local overheating.

Avoid exposure to air

Avoid rapid heating in air, because molybdenum easily reacts with oxygen to form MoO ₃ at high temperatures, especially when it exceeds 600°C. Inert gas protection can be used during preheating to prevent oxidation of the crucible surface.

Preheating suggestions:

Preheating temperature: between room temperature and 500°C, adjusted according to the temperature requirements and atmosphere conditions of the experiment.

Heating rate: 5–10°C per minute is recommended, especially for first-time use of molybdenum crucibles.

Heating method: Use a furnace with high temperature control accuracy to avoid overheating. It is recommended to use inert gas (such as argon, helium) for protection to avoid oxidation.

Maintain uniform temperature: During the heating process, ensure that the crucible is heated evenly to avoid local overheating.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595