To determine whether the molybdenum crucible needs to be replaced, a comprehensive assessment is required from four dimensions: appearance inspection, size change, performance test and usage record. The following is a specific judgment method:

- Appearance inspection

| Inspection items | Judgment criteria | Suggestions |

| Cracks and deformation | The surface has cracks, perforations or obvious deformation (such as dents, bulges) | Replace immediately to avoid the risk of cracking at high temperatures |

| Oxidation degree | purple oxide layer (MoO₃) appears on the surface or the thickness exceeds 0.1mm | Replacement, the oxide layer may fall off and contaminate the product |

| Corrosion and contamination | There are metal spots on the surface, slag adheres to the surface, or chemical reactions occur with the crucible material (such as the formation of sulfides). | Replace, corrosion will reduce the service life |

| Coating peeling | Surface protective coatings (such as zirconium oxide coatings) peel off and blister | Replacement, coating failure accelerates crucible oxidation |

- Size Change

| Test items | Eligibility criteria | Abnormal manifestations | Suggestions |

| Inner diameter change | Tolerance range: ± 0.1mm (e.g. original inner diameter 100mm, 99.9-100.1mm is allowed) | The inner diameter is reduced by more than 0.2mm or deformed | Replacement affects evaporation uniformity |

| Height Change | Tolerance range ± 0.5mm | The height is shortened by more than 1mm or tilted | Replacement may cause material leakage |

| Wall thickness variation | The wall thickness reduction does not exceed 20% of the original thickness |

- Performance Test

| Test items | Test Method | Failure criteria | Suggestions |

| Temperature resistance test | Keep at 1800℃ for 2 hours and observe the deformation | Obvious deformation or cracks | Replacement, high temperature performance degradation |

| Thermal shock test | Rapid cooling from 1800℃ to room temperature, repeated 5 times | Cracks or breaks | Replacement, thermal shock resistance failure |

| Metal contamination test | After evaporating high-purity metals, detect the impurity content in the metal | Impurity content exceeds 0.1% | Replacement, crucible material contaminates metal |

- Usage Record Analysis

| Using Parameters | Warning criteria | Suggestions |

| Cumulative usage time | More than 1000 hours (the specific time varies according to the process) | Evaluation and replacement, material performance degradation at high temperature |

| Use times | Evaporation times exceed 50 times (metal evaporation process) or smelting times exceed 30 times (alloy smelting) | Evaluate replacement, repeated thermal cycling accelerates wear |

| Process parameters | use at high temperatures above 2000℃ or under frequent thermal shock conditions | Shorten the replacement cycle to 500 hours |

5.Comprehensive Judgment Process

Check the appearance first: cracks, deformation, and oxidation are the primary indicators of replacement.

Secondary inspection dimensions: inner diameter, height, and wall thickness that are out of tolerance need to be replaced.

Performance test verification: If the high temperature, thermal shock, and contamination tests fail, the unit must be replaced.

Combined with usage records: if the accumulated time, number of times or process parameters exceed the standard, evaluation and replacement are required.

- Replacement suggestions

Safety first: If cracks or deformations are found, stop using and replace immediately to avoid the risk of high-temperature cracking.

Cost optimization: If there is only oxidation or slight wear, surface repair (such as re-spraying the protective layer) can be attempted, but the performance needs to be verified.

Regular maintenance: It is recommended to conduct an appearance inspection every 3 months and a dimensional inspection every six months to extend the service life.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

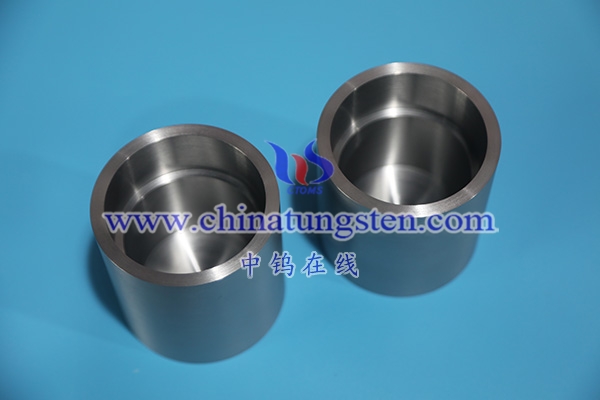

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595