Molybdenum crucibles can be heated at atmospheric pressure, but the temperature must be strictly limited and the environmental conditions must be controlled.

- Feasibility analysis of heating molybdenum crucible under normal pressure

Material properties

molybdenum is 2623℃. When heated to below 1800℃ under normal pressure, the molybdenum crucible can work stably without melting or structural failure.

High temperature oxidation risk: Molybdenum begins to react with oxygen above 400°C to generate volatile MoO₃, which causes the crucible to fail due to oxidation.

- Temperature Limitation

the molybdenum crucible under normal pressure, the temperature should be strictly controlled below 1800℃ to avoid accelerated oxidation.

Relationship between temperature and oxidation rate: For every 100°C increase in temperature, the oxidation rate increases by about 10 times.

Environmental Control

Inert atmosphere: Heating under vacuum or inert gas (such as argon) protection can effectively inhibit oxidation.

Reducing atmosphere: Hydrogen or carbon monoxide can be used to reduce the generated oxide layer, but the gas purity needs to be strictly monitored.

- Typical applications of atmospheric pressure heating molybdenum crucible

Metal evaporation

Used to evaporate high-purity metals (such as gold and silver), the temperature is controlled at 1500-1800℃ and must be carried out under the protection of inert gas.

Alloy Melting

For melting low melting point alloys (such as copper-based alloys), the temperature does not exceed 1200°C and can be operated for a short time in an air environment.

Ceramic sintering

Used for sintering ceramic materials such as zirconia, the temperature should be controlled below 1500℃, and chemical reaction with molybdenum should be avoided.

- Key Recommendations

the molybdenum crucible under normal pressure, the temperature must be strictly limited to below 1800°C, otherwise the risk of oxidation will increase dramatically.

Atmosphere protection: vacuum or inert gas protection is preferred to avoid oxidation and metal contamination.

Regular inspection: After heating, the crucible needs to be inspected for oxidation degree and size changes to ensure safety.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

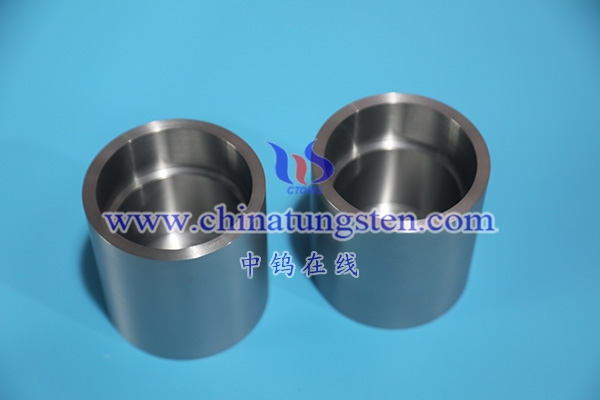

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595