To avoid the reaction between the molybdenum crucible and the melt, comprehensive measures should be taken from four dimensions: material selection, process control, environmental management, and surface treatment. The following are specific measures:

- Material selection

Matching melt material

do not react or react very little with molybdenum are preferred, such as gold, silver, copper, nickel and other low-melting-point metals.

Avoid highly active metals: Materials such as aluminum, titanium, and zirconium that easily form intermetallic compounds with molybdenum (such as MoAl ₂ and MoTi ₂) are prohibited.

Alloy selection: When melting alloys, it is necessary to ensure that there are no highly active elements in the alloy composition, or to inhibit the reaction by adding stabilizers (such as chromium).

Crucible purity control

Use high-purity molybdenum crucibles (purity ≥ 99.95%) to reduce the risk of impurities (such as iron, carbon) reacting with the melt.

- Process Control

Temperature Management

Upper temperature limit: The heating temperature should be strictly controlled below the temperature limit of the molybdenum crucible (usually ≤ 1800°C) to avoid the reaction rate increasing at high temperature.

Temperature gradient: Use slow heating/cooling process to reduce structural damage caused by thermal stress.

Time Control

Shorten the melting time: reduce the contact time between the melt and the crucible and reduce the probability of reaction.

Intermittent use: Avoid long-term continuous heating and cool the crucible periodically to restore surface stability.

Melt volume control

Filling rate limit: The melt volume shall not exceed 70% of the crucible volume to prevent the melt from expanding and overflowing or excessively contacting the crucible wall.

- Environmental Management

Atmosphere protection

Inert gas: Heating in an inert atmosphere such as argon or nitrogen to isolate oxygen and prevent oxidation reactions.

Vacuum environment: Use vacuum furnace for heating to completely eliminate the possibility of gas participating in the reaction.

Humidity Control

Dry environment: Ensure that the humidity in the furnace is ≤ 10% RH to prevent water vapor from reacting with the melt or crucible.

- Surface treatment

Coating protection

Zirconia coating: Spray zirconium oxide (ZrO ₂) coating on the inner wall of the crucible to form a physical barrier to isolate the melt from the molybdenum matrix.

Silicon carbide coating: suitable for high temperature environments, with a temperature resistance of up to 2000°C, but it is necessary to ensure that the coating is firmly bonded to the molybdenum substrate.

Pre-oxidation treatment

Surface passivation: Before the crucible is used, a dense MoO₂ layer is generated by low -temperature oxidation to slow down the oxidation rate at high temperatures.

- Operation Specifications

Preheating

Slow heating: It takes ≥ 2 hours from room temperature to working temperature to avoid thermal shock causing coating peeling or crucible cracking.

Cleaning and maintenance

Cleaning of melt residue: After each use, thoroughly clean the melt residue on the inner wall of the crucible to prevent reaction during the next heating.

Regular inspection: After every 50 uses, check the oxidation degree and coating integrity of the crucible inner wall.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

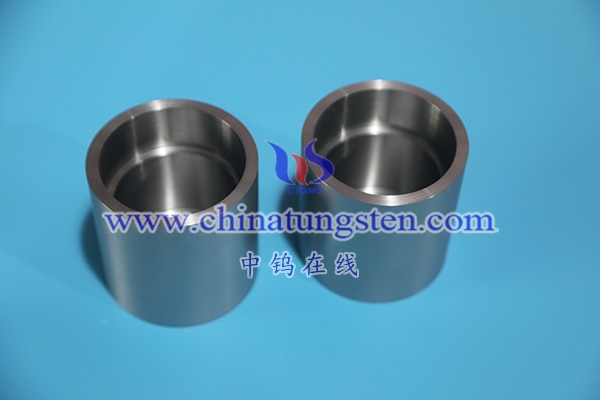

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595