After the molybdenum crucible is used, if it can no longer be used or has reached its service life, it should be discarded in an appropriate manner. As a metal material, molybdenum has a high melting point and stability, so special attention should be paid to its disposal. The following are several methods and precautions for the disposal of molybdenum crucibles:

- Recycling and reuse

Recycling of molybdenum materials: After the molybdenum crucible is used, recycling should be given priority, because molybdenum is a precious metal material, recycling and reuse can not only save resources, but also reduce the environmental burden. The recycling process of molybdenum usually includes melting, purification and reprocessing.

Find a suitable recycling channel: Some specialized metal recycling companies or manufacturers can recycle molybdenum crucibles, melt them and reprocess them. Such companies generally process waste molybdenum materials through high-temperature furnaces and other equipment.

- Molybdenum oxide waste treatment

Dealing with oxide layer: Molybdenum crucibles may form oxides (such as molybdenum trioxide MoO ₃) during high temperature use. Molybdenum oxide is a toxic substance, so appropriate measures should be taken to handle it. Avoid discarding it directly into the environment.

Treatment methods: Molybdenum oxide can be disposed of through specialized waste treatment procedures, such as converting molybdenum oxide into metallic molybdenum through high-temperature reduction treatment, or it can be sent to a hazardous waste treatment plant for treatment.

- Avoid direct disposal

Molybdenum crucibles are usually not discarded directly after being damaged, because the recycling value of molybdenum is high. Especially when the molybdenum crucible is not seriously damaged (such as cracks, broken, etc.), it should be recycled or reused as much as possible.

If the crucible is damaged, contains an oxide layer or other chemical contamination, it should be avoided to discard it directly into the ordinary garbage to prevent environmental pollution.

- Comply with local environmental regulations

disposing of molybdenum crucibles, local environmental regulations and industry standards should be followed. Some areas may have regulations requiring professional treatment of metal waste to avoid contamination of soil and water sources.

Some places may require that waste containing heavy metals such as molybdenum be sent to a designated waste treatment center for treatment.

- Dedicated waste storage containers

If the molybdenum crucible is broken or contains hazardous substances (such as molybdenum oxide), it should be stored in a dedicated waste container. Make sure the container can be effectively sealed to prevent the leakage of hazardous substances.

According to the specific conditions of the molybdenum crucible, choose a suitable storage method, such as a container made of anti-corrosion materials, to ensure that no secondary pollution is caused during the disposal process.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

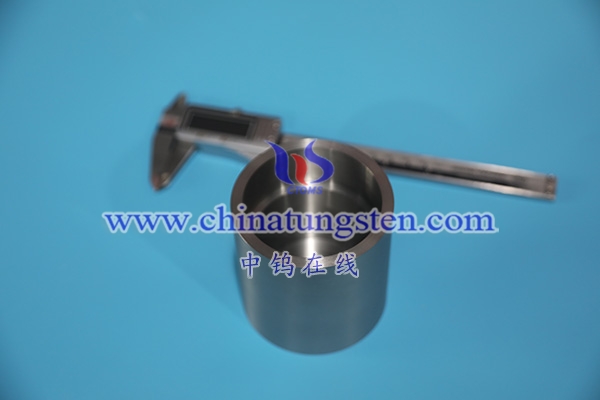

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595