To determine whether the molybdenum crucible contaminates the sample, a comprehensive evaluation is required from multiple dimensions such as component analysis, physical characterization, and experimental comparison. The following are the specific methods and steps:

- Composition analysis: Direct detection of molybdenum in samples

Spectroscopic analysis

Tools: Inductively coupled plasma optical emission spectrometer (ICP -OES) or inductively coupled plasma mass spectrometer (ICP -MS).

standard:

molybdenum content in the sample exceeds the background value (such as 0.01%), contamination may exist.

molybdenum content in a pure aluminum sample should not exceed 0.005%. If 0.02% is detected, it is considered contamination.

X-ray fluorescence spectroscopy (XRF)

Advantages: fast and non-destructive testing.

Application: Suitable for initial screening of large quantities of samples.

- Physical characterization: Observe sample surface and structural abnormalities

Surface morphology analysis

Tools: Scanning electron microscope (SEM) or transmission electron microscope (TEM).

Judgment basis:

Needle-shaped, granular or layered heterogeneous phases appear on the surface of the sample, which may be molybdenum or molybdenum oxides.

Example: In a metal melt, molybdenum contamination may form Carbide particles such as Mo₂C and MoC.

Lattice structure analysis

Tool: X-ray diffractometer (XRD).

standard:

If detected in the sample If the characteristic peaks of molybdenum or molybdenum compounds (such as the (110) crystal plane peak of MoO₂) are detected, it is judged as contamination.

- Experimental comparison: blank experiment and control experiment

Blank experiment

Operation: Without adding samples, use only molybdenum crucibles for the same process (such as melting, sintering).

Judgment basis:

molybdenum is detected in the blank experiment product, it means that the crucible itself is at risk of contamination.

Control experiment

operate:

The same experiment was carried out using a graphite crucible or a quartz crucible to compare the molybdenum content in the samples.

Judgment basis:

If the molybdenum content of the sample in the molybdenum crucible experiment is significantly higher than that in the control experiment, it is judged to be contaminated.

- Process Analysis: Tracing the Source of Pollution

Crucible use conditions

High temperature oxidation: If the crucible is used for a long time at > 800°C, MoO₃ may be generated and volatilize and contaminate the sample.

Reactive melts: Melts that are highly reactive with molybdenum (such as aluminum and titanium) are more likely to cause contamination.

Crucible surface condition

Oxide layer thickness: If the oxide layer on the crucible surface is > 0.1mm, the risk of contamination increases significantly.

Surface cracks: Cracks may become channels for the leakage of molybdenum.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

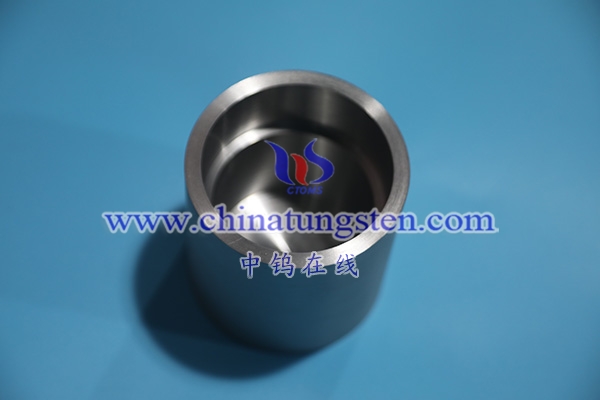

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595