Calibrate the temperature measurement in molybdenum crucibles, because accurate temperature control is critical to the performance and life of the molybdenum crucible. Errors in temperature measurement may result in damage to the crucible or incomplete reactions. Here are some common steps and methods to calibrate the temperature measurement in a molybdenum crucible:

- Choose the right temperature sensor

Thermocouple: Commonly used for high temperature measurement, especially in molybdenum crucibles. Thermocouple materials (such as platinum-rhodium alloys) can withstand high temperatures and are suitable for the temperature range of molybdenum crucibles. Choose a thermocouple type that matches the temperature range of the molybdenum crucible (such as K-type, S-type, etc.) to ensure that it can accurately measure the required temperature.

Infrared thermometer: can be used to measure surface temperature non-contactly, but in high temperature environments, it may be affected by changes in the atmosphere, so calibration is required to ensure accuracy.

- Select the calibration standard

Standard temperature sources: Standard temperature sources with known temperature values are used to calibrate measurement equipment, such as a high-temperature furnace, a standard temperature source (such as a black body radiation source), or a material with a known melting point. These standard temperature sources provide accurate and stable temperature values as a reference.

Substances with known melting points: Substances with well-defined melting points (such as aluminum, copper, or silver) can be used, and their melting points can be used as calibration standards. For example, the melting point of aluminum is 660°C and the melting point of copper is 1085°C.

- Perform temperature measurement calibration

Multi-point calibration method: In order to improve the measurement accuracy, a multi-point calibration method is used. This method involves measuring the temperature at different temperature points (such as 100°C, 500°C, 1000°C, etc.) and comparing the measured value with the actual value of the standard temperature source. Through multi-point calibration, a more accurate temperature measurement curve can be established to correct the nonlinear error of the temperature sensor.

Place the sensor at a standard position in the crucible: During calibration, ensure that the temperature sensor (such as a thermocouple) is aligned with a standard position inside the molybdenum crucible. This is usually the middle or melting area of the crucible, as this is the area where heat is most evenly distributed.

Calibration by adjusting the temperature control system: After comparing the sensor with a standard temperature source, check the settings of the temperature control system (such as a PID controller). If the measured value does not match the standard value, you can adjust the parameters of the temperature control system or the position of the temperature sensor.

- Regular calibration and maintenance

Regular calibration: Since temperature sensors drift over time, regular calibration is very important. The calibration cycle can be adjusted according to the frequency of use and device performance. It is generally recommended to calibrate once every six months or once a year.

Check the sensor and connection wires: During the calibration process, check whether the connection wires of the temperature sensor are intact, not worn or aged . Contact problems with the sensor wires may affect the accuracy of the temperature measurement.

- Compensation and correction

Temperature compensation: In high temperature environments, temperature deviations may occur due to factors such as atmosphere changes, thermal radiation, etc. The temperature compensation function can help correct these deviations and ensure accurate temperature measurement in the molybdenum crucible.

Use correction coefficients: If the errors measured at multiple temperature points are inconsistent, you can use correction coefficients to make adjustments. By determining the error curve, you can make corrections in actual use to make temperature measurement more accurate.

- Calibration Records and Verification

Record calibration data: After each calibration, keep a calibration record, including the temperature value of the standard temperature source, the measured temperature value and the details of any adjustments or compensation. This allows the calibration to be traced and verified at any time.

Verify calibration accuracy: In actual operation, the accuracy of temperature measurements should be verified regularly. Comparisons can be made with molten material of known temperature or other standard temperature sources to ensure that the temperature control system continues to work accurately.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

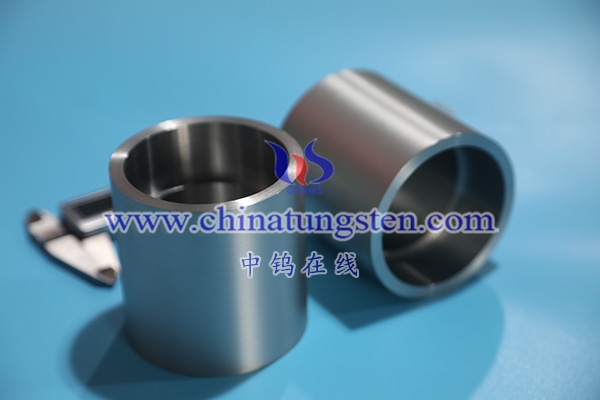

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595