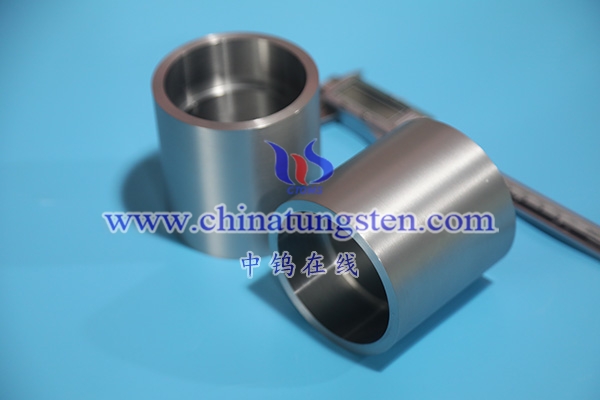

Molybdenum crucibles is a common problem when molybdenum materials are exposed to oxygen or other oxidizing gases under high temperature conditions. Molybdenum oxidation will cause a layer of molybdenum oxide (such as MoO₃) to form on the surface of molybdenum. This oxide layer may affect the performance of the crucible, especially in high temperature, chemical reaction and other environments. If the oxidized molybdenum crucible is not treated, it may lead to a decrease in strength, shortened service life and even cracking. In order to restore its performance, the oxidized surface of the molybdenum crucible can be treated in the following ways:

- Mechanical cleaning

Remove the oxide layer: Use sandpaper, diamond grinding wheel or other grinding tools to remove the oxide layer on the surface of the molybdenum crucible. In this way, the oxide can be removed and the smoothness of the metal surface can be restored. When performing mechanical cleaning, it is necessary to control the pressure and speed to avoid excessive wear or damage to the molybdenum crucible body.

the molybdenum crucible is further processed by using polishing tools and polishing agents to remove tiny oxide layers and wear marks. This not only helps to restore the gloss of the molybdenum surface, but also further reduces the surface roughness.

- Chemical cleaning

Chemical deoxidation: The oxide layer can be removed by using chemicals (such as hydrofluoric acid, sulfuric acid, etc.). This method can effectively remove oxides on the surface of molybdenum, but you need to be very careful because these chemical reagents are highly corrosive. Wear protective equipment when using it to ensure safe operation.

Pickling: Pickling is a common method for removing the molybdenum oxide layer, especially using hydrofluoric acid solution, which can quickly and effectively dissolve the molybdenum oxide. The crucible needs to be thoroughly cleaned after use to ensure that no acid residue remains.

- Heat treatment or reduction treatment

The molybdenum crucible can be heated in an inert gas environment (such as argon) to reduce the molybdenum oxide to metallic molybdenum through a reduction reaction. During the heating process, the oxide is reduced to gas (water vapor or oxygen) and released, thereby restoring the original metal properties of the molybdenum crucible.

High temperature heat treatment: Placing the molybdenum crucible in a high temperature environment (usually between 1200°C and 1600°C) and treating it in an oxygen-deficient or low-oxygen environment can promote the decomposition or reduction of oxides. This method usually requires long-term heating to remove oxides.

- Electrochemical deoxidation

Electrolytic deoxidation: In a suitable electrolytic cell, a molybdenum crucible is used as the cathode and an appropriate electrolyte (such as dilute sulfuric acid solution) is used for electrolytic deoxidation. Under the action of an electric field, molybdenum oxide can be reduced to molybdenum metal. This method is more efficient, but the electrolysis current and solution concentration need to be controlled during operation.

- Apply protective layer

Coating with anti-oxidation coating: If the oxide layer on the surface of the molybdenum crucible has been removed, but you still want to prevent it from being oxidized again, you can consider coating it with an anti-oxidation coating. These coatings (such as carbon coatings, ceramic coatings, etc.) can effectively protect the surface of the molybdenum crucible and prevent oxidation. The coating can not only reduce the oxidation of the molybdenum crucible, but also improve its durability in high temperature and chemical environments.

- Prevent oxidation

Control the working environment: In order to avoid oxidation, you can control the working environment when using the molybdenum crucible, use argon, nitrogen and other inert gases to fill the furnace to ensure that the molybdenum crucible is not exposed to oxygen. During the heating or melting process, maintaining a low oxygen atmosphere helps reduce the occurrence of oxidation.

Use low temperature start-up: Avoid the molybdenum crucible from room temperature directly into a high temperature environment, and slowly increase the temperature to avoid oxidation caused by excessive temperature differences. Gradually increasing the temperature can effectively reduce the oxidation rate and extend the service life of the crucible.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595