Molybdenum crucible is affected by multiple factors such as raw material cost, production process, market supply and demand, product specifications and brand. The specific analysis is as follows:

- Raw material cost

Molybdenum metal price fluctuations

molybdenum directly affects the cost of molybdenum crucibles. For example, in March 2025, the price of molybdenum concentrate dropped from about 3,530 yuan/ ton at the beginning of the month to 3,330 yuan/ton on the 20th, a decrease of 5.67%, resulting in a decrease in the price of molybdenum products.

molybdenum metal, international market prices, exchange rate fluctuations and other factors will all be transmitted to the price of molybdenum crucibles.

Auxiliary material cost

Changes in the costs of additives, coating materials, etc. used in the production process will also affect the final price.

- Production technology and quality

Manufacturing process complexity

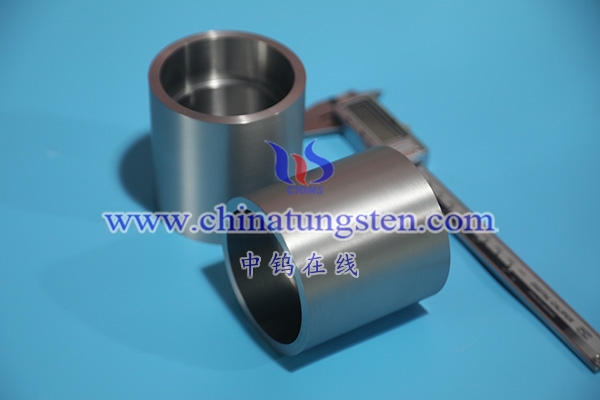

There are significant cost differences between sintered, stamped and welded processes. For example, welded crucibles are slightly more expensive, but they last longer and cost less in the long run.

Optimization of the production process (such as adjustment of sintering parameters) can improve material utilization, reduce energy consumption, and thus affect prices.

Quality Standards

Molybdenum crucibles with high purity (≥99.95%) and high density (≥9.8g / cm³) have higher prices due to their superior performance.

Quality indicators such as surface finish and dimensional accuracy will also affect the price.

- Market supply and demand relationship

Supply Side

The output of molybdenum ore and the mining of copper-molybdenum associated minerals directly affect the supply of molybdenum metal. For example, the world’s largest single molybdenum mine is expected to be completed and put into production in mid-2027, with an average annual output of about 27,200 tons of molybdenum , but the future supply increase will be limited.

Rising production costs (such as increased environmental protection requirements) may lead to reduced supply and push up prices.

Demand side

molybdenum crucibles in high-growth areas such as military aerospace, automobiles, new energy equipment (such as lithium carbonate, lithium hydroxide reactors), and wind power castings, and the growth in demand will support prices.

Seasonal demand changes, such as increased demand in the steel industry during winter, can also affect price fluctuations.

- Product Specifications and Customization

Size and Capacity

molybdenum crucibles with diameters ranging from Φ 10mm to Φ 400mm and heights from 10mm to 500mm vary significantly. For example, a crucible with a diameter of 30-50mm and a wall thickness of 0.3-10mm will have a different price than a crucible with a diameter of 50-100mm and a wall thickness of 0.5-15mm.

Customization requirements (e.g. special sizes, coatings) will increase production costs and thus affect prices.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595