Purchasing a molybdenum crucible, you need to pay attention to a series of technical and performance parameters to ensure that it is suitable for specific application requirements. Here are some key parameters:

- Purity

Purity level: The purity of the molybdenum crucible will directly affect its performance and service life. Generally speaking, high-purity (such as 99.95% or higher) molybdenum crucibles have better oxidation resistance, high temperature resistance and chemical stability. If the application requires particularly high purity, it is more appropriate to choose a high-purity molybdenum crucible.

Impurity content: Confirm whether the molybdenum crucible contains other metal impurities or alloy elements, which may affect the chemical stability of the crucible and the smelting process.

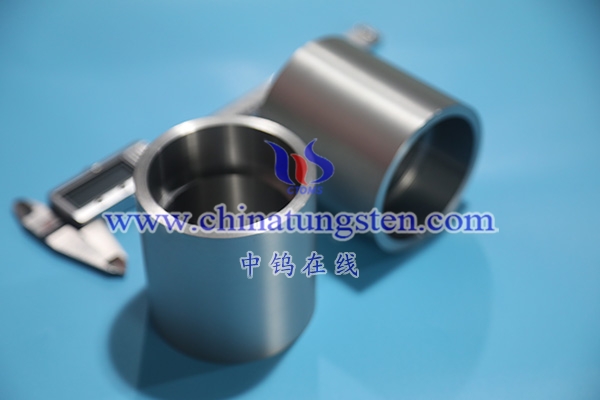

- Size and volume

Size: The diameter, height and volume of the molybdenum crucible should be determined according to actual needs. Before purchasing, make sure that the size of the crucible can meet your experimental or production needs.

Volume: Choosing the right volume is critical for applications such as melting or crystal growth. Typically, larger crucibles are used for larger scale melting processes, while smaller crucibles are suitable for precision experiments.

- Wall thickness

Wall thickness: Wall thickness affects the crucible’s heat transfer efficiency and resistance to deformation. Thicker walls can increase the crucible’s durability, especially in high temperature environments, to avoid deformation or cracking due to thermal expansion. Thinner walls help improve heat transfer efficiency and reduce heat loss.

Uniformity: The wall thickness of the crucible should be uniform to avoid cracking or uneven heating due to thermal stress.

- Antioxidant

Oxidation performance: Molybdenum materials are prone to form molybdenum oxide (MoO₃) in high-temperature oxidizing environments, which will affect its service life. It is necessary to understand the oxidation protection treatment of molybdenum crucibles, such as surface coatings or special heat treatment processes. High-quality molybdenum crucibles usually have strong oxidation resistance, can withstand high temperatures and are not easily oxidized.

Surface treatment: Some molybdenum crucibles may undergo special surface treatments such as molybdenum oxide coating and carbon coating to enhance oxidation resistance.

- High temperature resistance

Maximum operating temperature: It is very important to understand the maximum temperature that the molybdenum crucible can withstand, especially in applications such as high-temperature smelting and crystal growth. Generally, molybdenum crucibles can be used at temperatures exceeding 3000°C, but the specific temperature resistance will vary depending on the purity of the molybdenum and the surface treatment process.

Thermal shock resistance: Check the thermal shock resistance of the crucible to avoid cracking in an environment with rapid changes in high temperature.

- Corrosion resistance

Chemical stability: Molybdenum crucibles need to withstand various chemical corrosion for a long time in a high temperature environment, especially corrosion from molten metals, chemical reagents or other reactive substances. Confirm whether the molybdenum crucible is suitable for a specific chemical reaction or metal smelting to avoid material failure.

Scope of application: Some molybdenum crucibles may have poor corrosion resistance to certain metals or chemicals, so it is necessary to confirm their applicable working environment.

- Processing technology

Manufacturing process: The manufacturing process of molybdenum crucible, such as casting, forging, spinning, etc., will affect its structural strength, dimensional accuracy and surface quality. Select the crucible process that matches the application requirements.

Molybdenum crucibles with higher surface smoothness can not only improve heat conduction efficiency, but also reduce surface defects and extend service life.

- Mechanical strength

Anti-deformation ability: When the molybdenum crucible is used at high temperature, it may be affected by factors such as thermal expansion and pressure. Understand its anti-deformation ability and choose a molybdenum crucible with higher strength and crack resistance.

Impact resistance: The crucible may be subjected to external impact or pressure, so the impact resistance of the molybdenum crucible is also an important consideration.

- Temperature control characteristics

Uniform heating capability: The thermal conductivity of the molybdenum crucible affects the uniformity of heating. Uniform heating can ensure the stability and consistency of the reaction process and reduce damage caused by thermal stress.

Coefficient of Thermal Expansion: Understand the coefficient of thermal expansion of the crucible to avoid cracks or deformation during use.

- Costs and Suppliers

Price and quality: When choosing a molybdenum crucible, you need to weigh the price and quality to ensure that you choose a product with high-cost performance. When purchasing, you need to consider its life cycle cost, including maintenance, use and replacement cycle.

Supplier reputation: Choose suppliers with good reputation and good reputation, ensure that the purchased molybdenum crucibles meet the relevant quality standards, and provide good after-sales service.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595