To verify the quality of molybdenum crucibles, a comprehensive evaluation is required from four dimensions: raw material purity, production process, performance testing, and appearance and size. The following are the specific methods:

- Raw material purity verification

Chemical composition analysis

Method: Molybdenum content is measured by spectroscopic analysis (such as ICP -OES) or X-ray fluorescence spectroscopy (XRF).

Standard: The molybdenum content of high-purity molybdenum crucible must be ≥99.95%, and the impurity content (such as iron, nickel, carbon, etc.) must be less than 0.05%.

Case: If the molybdenum content is lower than 99.9%, it may cause oxidation at high temperatures or a decrease in melting point, thus shortening the service life.

Metallographic structure inspection

Method: Observe the internal structure of the material through a metallographic microscope to confirm that there are no defects such as inclusions and holes.

Significance: Uniform and dense metallographic structure can improve high temperature resistance and thermal shock resistance.

- Production process verification

Density test

Method: Density is measured by Archimedes drainage method, or internal density is tested non-destructively by ultrasonic wave.

Standard: The density of sintered molybdenum crucible must be ≥9.8 g/cm³. Porosity may exist below this value, affecting thermal conductivity and mechanical strength.

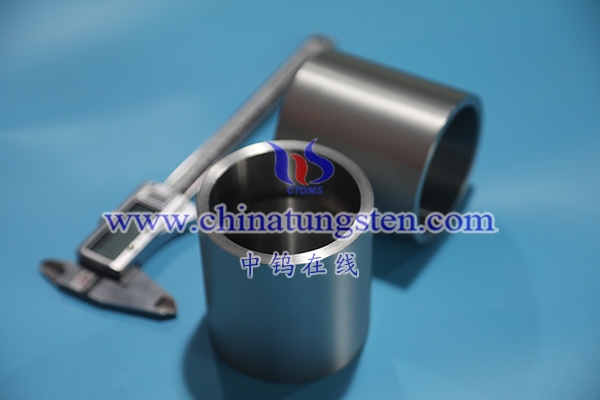

Dimensional accuracy inspection

Method: Use a three-coordinate measuring machine or caliper to measure the inner diameter, outer diameter, height and wall thickness of the crucible. The tolerance must be controlled within ± 0.1mm.

Significance: Dimensional deviation may cause the crucible to not match the heating equipment, affecting thermal efficiency.

Surface treatment evaluation

Method: Visually check whether the surface is smooth, without cracks, scratches or oxide layer; check the corrosion resistance by salt spray test.

Standard: Surface roughness Ra≤1.6μm, no visible defects.

- Performance Test Verification

High temperature performance test

Method: Place the crucible in a high-temperature furnace, raise the temperature to above 2000℃, keep it warm for 2 hours, then cool it naturally and observe whether it is deformed or cracked.

Standard: No obvious deformation at high temperature and no cracks after cooling.

Antioxidant Test

Method: Heat in air at 1200℃ for 100 hours and weigh to detect oxidation weight gain.

Standard: Oxidation weight gain rate ≤ 0.5mg /cm²·h, high-quality molybdenum crucible can be as low as 0.1mg /cm²·h.

Thermal shock test

Method: Rapidly cool the crucible from 2000°C to room temperature (such as water quenching), repeat 10 times, and check whether it cracks.

Significance: To simulate the sudden temperature change in actual use and verify the thermal shock resistance.

- Appearance and size verification

Appearance inspection

Method: Check visually or with a magnifying glass whether the surface is smooth and free of pores, cracks, inclusions or oxidation spots.

Standard: Surface defect area ≤ 1% of the total area, no obvious scratches.

Dimensional tolerance

Method: Use a vernier caliper or a three-coordinate measuring machine to check the inner diameter, outer diameter, height and wall thickness.

Standard: The tolerance range depends on the application scenario. For example, precision casting needs to be controlled within ± 0.05mm.

- Other Verification Methods

Ultrasonic flaw detection

Method: Use ultrasonic detection to detect whether there are internal defects such as delamination and cracks.

Significance: Ensure the integrity of the internal structure of the crucible to avoid failure at high temperatures.

X-ray Inspection

Method: Use X-ray fluoroscopy to check internal defects such as pores, inclusions, etc.

Application: Suitable for scenarios with extremely high requirements on internal quality.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595