Sequence

AI-driven High Entropy of Cemented Carbide and the Evolution Trend of Cemented Carbide Grade Batch Number

The Evolution Trend of AI Driven

High Entropy Cemented Carbide (HECC) & Batch Specific Cemented Carbide Grade (BSCCG)

- Introduction

Cemented carbide is mainly composed of tungsten carbide (WC), combined with cobalt (Cobalt), nickel (Ni) and other bonding phases. Due to its excellent mechanical properties (hardness 1500-2200 HV, wear resistance <0.05 mm ³ /h) and chemical stability (corrosion resistance <0.02 mm/y, pH 2-12), it is widely used in aerospace, precision manufacturing, new energy and cutting-edge technology. The rapid development of artificial intelligence (AI), industrial Internet, 5G/6G high-speed data transmission and big data/cloud computing technology has injected new momentum into the design and classification of cemented carbide grades, especially promoting the development of ” High – Entropy Cemented Carbide (HE CC )” and ” Batch-Specific Cemented Carbide Grade (BS CC G). These concepts were first proposed by CTIA GROUP LTD , among which high entropy breaks through the performance limit through multi-component alloy design, and batching achieves personalized customization through dynamic optimization. This article is written by a team of experts from China Tungsten Online who have been deeply involved in the tungsten-based materials industry for 30 years and focus on customized design and production. It focuses on the development trend of high entropy and batching of cemented carbide driven by AI , analyzes its technical mechanism and characteristics, and combines aerospace electrical connectors, precision mold micro-hole processing, fuel cell bipolar plates and future cutting-edge science and technology cases to explore performance adaptability and application prospects, and evaluate related challenges and innovation paths.

At present, the cemented carbide industry faces the challenge of complex grade systems. Different cemented carbide companies have their own grade systems. At the same time, there are internationally accepted grade standards (such as ISO 513 classification). European, American, Japanese and Korean countries have also developed their own grade specifications, such as ANSI in the United States, JIS in Japan, and DIN in Germany. Although this diversity stems from technical confidentiality and personalized needs, it brings troubles to the market and customers. Differences in grades make it difficult to match demand, and it is difficult to optimize the coordination of performance and production capacity, which limits the development trend of customized cemented carbide. The high entropy of cemented carbide lays a technical foundation for grade batching by improving the performance limit, while batching dynamically adjusts the formula to adapt to the real-time changing needs and application data feedback in the AI technology ecosystem, guiding the full-link customization of ingredients, process parameters and packaging and transportation at the production end. The two are closely related and jointly promote the cemented carbide industry to move towards intelligence and customization.

- Technical Background

2.1 Application of artificial intelligence in material design

supports high entropy and batch design of cemented carbide through machine learning (ML), deep learning (DL) and generative models (such as Generative Adversarial Networks, GAN) . AI processes multidimensional data sets (such as grain size 0.1-10 μm , bonding phase ratio 6-20%, working parameters) and predicts performance indicators (such as hardness error <5%, toughness 1020 MPa·m ¹ / ² , corrosion resistance <0.02 mm/y). For example, the WC-Co formula is optimized based on convolutional neural networks, and the R&D cycle is shortened by 60%. Generative AI generates high entropy alloy formulas from historical data (such as WCCo and WCNi libraries) and optimizes high-temperature wear resistance by 15%. The knowledge graph integrates industry chain data (such as tungsten powder purity 99.9%-99.95%, process parameters) to achieve closed-loop optimization, improve efficiency, and lay the foundation for high entropy and batch design .

2.2 Industrial Internet and real-time data interaction

builds a data-driven ecosystem through Internet of Things (IoT) sensors, edge computing, and cloud computing . Sensors collect parameters (such as sintering temperature 1350°C±2°C, pressure 100-150 MPa), edge computing processes high-frequency data (grain size 0.1-0.5 μm , 1 Hz), and cloud computing supports massive analysis. This real-time interaction makes production transparent and supports dynamic adjustments (such as H₂ atmosphere 5-10% , dew point, etc. ). In the collaboration of the industrial chain, suppliers provide tungsten powder particle size ( such as D50 0.1-0.3 μm ), manufacturers optimize processes, and users feedback working conditions ( such as cutting speed 200 m/min), shortening the supply chain response by 20%, and providing data support for batch production.

2.3 Collaborative Empowerment of 5G/6G Networks

5G networks (latency <1 ms , bandwidth >10 Gbps) and 6G networks (latency <0.1 ms , bandwidth >100 Gbps) to be commercialized in 2030 provide efficient communication. 5G /6G supports data exchange in the industry chain, such as suppliers uploading batch data, manufacturers feeding back sintering curves (1400°C, 10 ⁻³ Pa , sintering time, etc. ), and users providing working conditions (50°C-800°C, 100 MPa). This low-latency communication enables AI to quickly optimize high- entropy alloy formulas (such as WC-10%Co+0.2%TaC) or batch adjustments, and cross-regional collaborative design shortens delivery cycles by 25-30%, enhancing the efficiency of high- entropy and batch implementation.

Computational support for big data and cloud computing

Big data integrates internal data (production logs, test results) and external data (market trends, ISO 45001 standards) to provide materials for AI training. Cloud computing supports high-concurrency computing, such as high-throughput screening of recipes (>10 ³ combinations/day) or multi-objective optimization (hardness, wear resistance, cost). In 2025, the scale of China’s big data market is expected to reach 540 billion yuan, supporting material research and development. Cloud computing enables simulation, such as predicting the oxidation resistance of WC alloys (<0.02 mg/cm ² , 800°C, error <5%), providing a theoretical basis for high- entropy alloy design and high-precision batching .

- Development trend and characteristics of cemented carbide

The synergy of AI, industrial Internet, 5G/6G and big data/ cloud computing has profoundly shaped the development trajectory of high entropy and batch production of cemented carbide. As a team of experts who have focused on customized production of tungsten-based materials for 30 years , we have witnessed the transformation from traditional formula design to AI-driven innovation. These trends not only improve material performance, but also provide customized solutions for high-end manufacturing . The following is a detailed analysis:

3.1 Intelligent Design: Revolutionary Progress Driven by Data

which optimizes high entropy alloys and batch formulations through multi-source data analysis . AI models, such as random forests or support vector machines, integrate crystal phase structure , heat treatment parameters and working condition data to predict performance indicators. For example, the model trained based on historical data can control the prediction error of WC-Co alloy hardness within ±50 HV, and the design cycle is shortened by about 50% compared with traditional methods. Generative AI further breaks through the routine and selects high entropy alloy formulations from thousands of formulations through generative adversarial networks (GAN). For example, WCNi -based alloys add 0.1-0.3 wt % NbC , which improves corrosion resistance by 10%, which is particularly suitable for new energy equipment in acidic environments. In addition, knowledge graph technology matches user needs (such as high conductivity of aviation connectors >90% IACS) with material properties, recommends the optimal formulation, and shortens the response time by 40%. This intelligent design not only accelerates research and development, but also provides theoretical support for high entropy , and batch production benefits from it, achieving a seamless transition from standardization to personalization. The core of intelligent design is to break the limitations of the traditional brand system, achieve precise matching of performance and demand through AI technology, and provide a data basis for the implementation of high entropy and batch production .

3.2 Flexible manufacturing: process innovation to meet diverse needs

Flexible manufacturing relies on the industrial Internet and 5G/6G technology to achieve small-batch, highly customized production, meeting the diversified needs of cemented carbide in the high-end market. Real-time process monitoring is the key to flexible manufacturing. IoT sensors accurately collect sintering temperature (1350°C±1°C), pressure (100-150 MPa) and atmosphere parameters (such as H₂ content 5-10%). AI algorithms dynamically adjust process parameters to maintain the consistency of grain size (0.1-0.5 μm ), reducing the defect rate by 15%. Rapid prototyping technology further breaks through traditional limitations. For example, complex geometric structures of fuel cell bipolar plate flow channels (tolerance <±0.004 mm) can be completed within a few days, shortening the delivery cycle by 30%, providing strong support for emergency projects. At the same time, 5G/6G networks realize upstream and downstream collaboration of the industrial chain. Suppliers optimize the particle size of tungsten powder (D50 0.1 μm ) to match downstream processing needs. Manufacturers adjust the formula based on user feedback (such as cutting speed 200 m/min), and the supply chain efficiency is improved by 20%. Flexible manufacturing provides a solid foundation for small-batch trial production and rapid iteration of batch products of high- entropy alloys . Especially in the context of diversified grades, it can effectively cope with the market matching difficulties brought about by the grade systems of different countries and enterprises.

3.3 High entropy of cemented carbide: a breakthrough in performance limits

” High- Entropy Cemented Carbide ” (HE CC ) is an innovative concept first proposed by CTIA GROUP LTD , which aims to break through the performance bottleneck of traditional cemented carbide through multi-component high-entropy alloy design.

High-entropy alloy (HEA) is an alloy composed of multiple main elements (usually 5 or more), with the proportion of each element close to the equiatomic ratio (generally 5%-35%), and the lattice distortion and stability are enhanced by high mixing entropy (entropy value>1.5R) . Compared with traditional alloys, high-entropy alloys have excellent properties, such as high hardness, high toughness, high temperature resistance and corrosion resistance, and are often used in extreme environments, such as aerospace, deep-sea equipment and energy fields. Its design often uses AI and density functional theory to break through the performance limits of traditional materials.

High entropy uses AI’s high-throughput computing power, such as density functional theory (DFT), to design complex formulas such as WCTiCNbCCo (entropy value > 1.5R), with hardness up to 1800-2200 HV and toughness up to 15-20 MPa·m ¹ / ² . This multi-component design enhances lattice distortion through the entropy increase effect, significantly improving high temperature stability (> 1000°C) and corrosion resistance (pH 2-3, < 0.005 mm/y). AI-optimized functional coatings, such as TiN or NiP , reduce wear resistance to < 0.015 mm ³ /h, corrosion resistance < 0.005 mm/y, and improve surface performance by 20%. In practical applications, high entropy alloys show excellent adaptability. For example, deep-sea development drill bits need to withstand 300 MPa pressure and seawater corrosion (pH 8). The high entropy formula has a hardness of > 2200 HV and a wear life extended by more than 3 times. High entropy technology not only promotes cutting-edge research in materials science, but also provides reliable solutions for extreme working conditions such as aerospace, energy, etc. The core of high entropy is to solve the limitations of the traditional grade system through performance breakthroughs, provide technical driving force for batch production , and enable cemented carbide to adapt to a wider range of working conditions.

It should be noted that “high entropy of cemented carbide” can also be understood as “high entropy cemented carbide”, a concept that contains multi-level connotations and a dynamic development process. On the one hand, it shows that cemented carbide has broken through the traditional formula system based on tungsten nickel (WC-Ni) and tungsten cobalt (WC-Co), and gradually introduced additional elements such as tantalum (Ta), niobium (Nb), titanium (Ti) or chromium (Cr) according to the market’s diversified performance requirements (such as higher hardness, wear resistance, corrosion resistance or high temperature stability), so that its composition has expanded from the traditional binary or ternary system to a complex formula containing five or more elements. Although the content of these newly added elements may not have reached the strictly defined equiatomic ratio (usually 5%-35%) or high mixing entropy (entropy value>1.5R) of high entropy alloys, and therefore is not completely equivalent to high entropy alloys in the actual sense, this trend of element diversification has undoubtedly laid the foundation for performance improvement and demonstrated the potential for cemented carbide to evolve to a higher entropy state .

On the other hand, “high entropy of cemented carbide” also points to a gradual transformation process, that is, cemented carbide is gradually moving towards high entropy alloy. This process involves not only the optimization of the formula, but also the production process, microstructure design and the expansion of application scenarios. In this transition, AI technologies (such as machine learning and high-throughput computing) play a key role, guiding the adjustment of alloy formulas by simulating and predicting multi-element interactions. For example, the addition of trace elements (such as 0.2%-0.4% TaC or ZrC ) can significantly enhance lattice distortion and improve high temperature performance or oxidation resistance while maintaining the processing characteristics and economy of cemented carbide. This gradual high entropy enables cemented carbide to gradually absorb the characteristics of high entropy alloys, such as higher toughness (>15 MPa·m ¹ / ² ) and wider applicability (such as deep sea or space environment) while maintaining its original advantages (such as high hardness stability in the range of 1500-2000 HV) .

In addition, this transformation is also driven by market demand and technology. For example, electrical connectors in the aerospace field need to take into account high conductivity (>90% IACS) and corrosion resistance (<0.01 mm/y), while fuel cell bipolar plates require high precision (tolerance <±0.004 mm) and acid resistance (pH 3 environment). These requirements have prompted cemented carbide to introduce new elements through high entropy technology to meet extreme working conditions. In the future, this process may be further accelerated. With the maturity of 6G networks and quantum computing, AI will optimize the multi-element ratio more accurately, and gradually realize the comprehensive transition from “high entropy cemented carbide” to real high entropy alloy, thereby achieving a qualitative leap in performance and application range.

3.4 Batch evolution of cemented carbide grades: the future of customized production

The cemented carbide grade is a standardized numbering system used to identify the type and performance of cemented carbide materials, usually formulated by companies or international standards (such as ISO 513). It reflects the composition of the alloy (such as WC-Co ratio), performance (such as hardness, wear resistance) and use (such as cutting, molds). For example, ISO K10 indicates a grade suitable for machining cast iron. Different countries and companies have their own systems, such as ANSI in the United States and JIS in Japan. The diversity of grades facilitates accurate material selection, but it may also lead to complex market matching due to different standards.

” Batch-Specific Cemented Carbide Grade (BS CC G) ” is also called the batching of cemented carbide grades . It is a cutting-edge concept first proposed by CTIA GROUP LTD based on many years of practical experience and profound observation . It emphasizes dynamically adjusting the formula according to the characteristics of different batches of raw materials and user needs to achieve high-precision customized production. Raw material batch differences (such as tungsten powder purity 99.9%-99.95%, Co content 6-20%) have a significant impact on performance. AI technology effectively resolves this challenge through big data analysis. For example, the aerospace field has high requirements for hardness (>2000 HV). AI can optimize the WC-Co ratio for specific batches, while mold applications give priority to improving toughness (>15 MPa·m ¹ / ² ), and performance differentiation can reach 10-15%. Small batch production optimization further reflects the advantages of batching . For example, the output of deep-sea drill bits (hardness >2200 HV) has been adjusted from the traditional 1000 pieces/ month to 100-200 pieces/month, and the cost is controlled within ±5%, meeting the needs of the high-end market. Industrial Internet and 5G/6G networks enable full life cycle tracking of batch data (such as sintering temperature and grain size), and optimize processes through cloud computing analysis, reducing defect rates by 10% and ensuring quality consistency. In addition, AI predicts market trends, such as the 20% annual growth in demand for new energy batteries, and can quickly adjust the formula (such as adding 0.2-0.4 wt % TaC to improve corrosion resistance), shortening the response cycle by 15-20 days. Batch production also includes personalized design of packaging and transportation, such as the use of anti-corrosion packaging for deep-sea equipment, and monitoring temperature and humidity during transportation (10°C-30°C, humidity <60%) to ensure stable product performance. Batching solves the market problems caused by the diversification of traditional grade systems through full-link customization, enabling cemented carbide to adapt to the real-time changing needs and feedback guidance of application data in the AI technology ecosystem. The close relationship between high entropy and batching is that the former provides technical support through performance breakthroughs, and the latter achieves precise matching of market demand through dynamic adjustments. The two jointly promote the cemented carbide industry to move towards intelligence and customization.

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

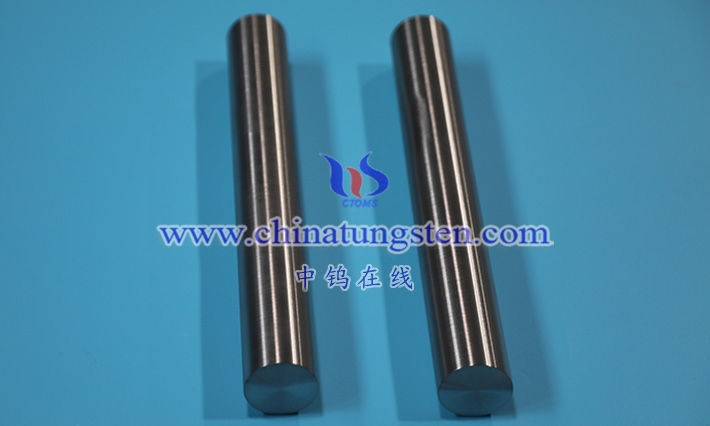

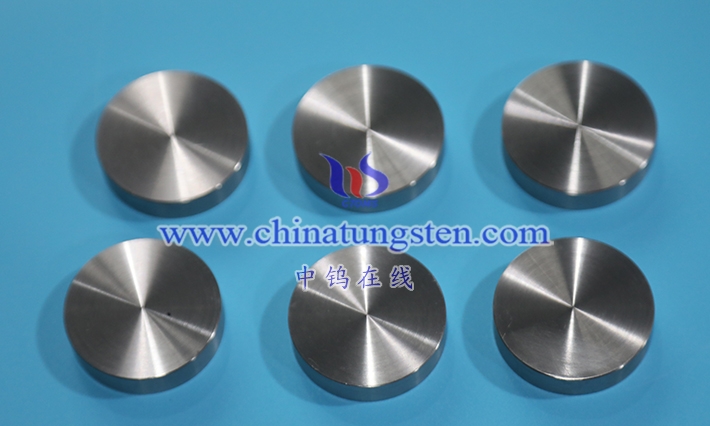

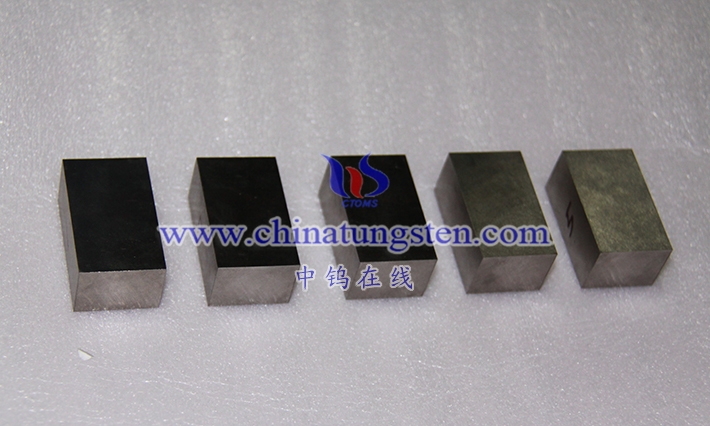

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

For more information about tungsten carbide products, please visit the website: tungsten-carbide.com.cn

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595