Chapter 2: Microstructure and Phase State of Cemented Carbide

Microstructure & Phase States of Tungsten Cemented Carbide

With its unique microstructure and phase characteristics, cemented carbide has become the core of high-performance materials in modern industry. Its microstructure is composed of hard carbide particles, tough bonding phase and complex interface system, while the phase characteristics involve the distribution of crystal structure, solid solution, defects and amorphous phase. These microscopic characteristics determine the performance of cemented carbide at the atomic and crystal levels, such as wear resistance, toughness and processing reliability. This chapter focuses on the microstructure and phase of cemented carbide, systematically analyzing the characteristics of carbide particles, the distribution and role of bonding phase, the formation mechanism of interface and defects, and advanced characterization technology. Through theoretical analysis, experimental data and actual cases, this chapter aims to reveal the regulation mechanism of microstructure on performance, provide a scientific basis for process optimization and application of cemented carbide, and provide a reference for cross-disciplinary research in the field of materials science and engineering.

2.1 Microscopic characteristics of carbide particles

Carbide particles are the hard skeleton of cemented carbide, mainly composed of tungsten carbide (WC), supplemented by titanium carbide ( TiC ), tantalum carbide ( TaC ), etc., which jointly determine the mechanical properties and environmental adaptability of the material. This section discusses the microscopic characteristics of carbide particles from the perspective of grain size, morphology and multiphase synergy.

2.1.1 WC grain size and morphology

Tungsten carbide (WC) grains are the main hard phase of cemented carbide, and their size (0.110μm) and morphology directly affect the performance of the material. WC has a hexagonal crystal structure (P6m2 space group, lattice constant a=2.906 Å , c=2.837 Å ), and the covalent bond energy of WC is about 6 eV±0.2 eV, which gives it high hardness and wear resistance. The regulation of grain size is the core of cemented carbide performance optimization. For example, when the grain size is reduced from 5μm to 0.5μm, the grain boundary density increases, the hardness is significantly improved, and the toughness decreases slightly.

Scanning Electron Microscope ( SEM) analysis shows that the WC grain size in conventional cemented carbide is 12μm±0.2μm, with a prismatic morphology (angles 60°90°), mainly exposing the (0001) and (1010) crystal planes. This morphology enhances wear resistance due to anisotropy (hardness in the <0001> direction is about 10% higher), making it suitable for high-load applications such as cutting tools. For example, when a cemented carbide tool containing 1.5μm grains is cutting steel (tensile strength>1000 MPa), the wear loss is <0.1mm and the service life is 12 hours±1 hour.

Nano-scale cemented carbide (grains <0.2μm) tends to be spherical, with a surface energy of up to 1 J/m² ± 0.1 J/ m² . Due to the increase in the proportion of grain boundaries (>50%), the hardness is further improved, making it suitable for ultra-precision processing, such as semiconductor wafer cutting (surface roughness Ra<0.01μm). However, nano-grains are prone to agglomeration (agglomeration rate 10%15%), resulting in a porosity increase to 1%±0.2%. Spark plasma sintering (SPS, 1200°C, 50 MPa) controls agglomeration by rapid heating (>100°C/min), reducing the porosity to <0.5%±0.1% and the grain size deviation to <5%.

The regulation of grain morphology depends on the sintering process. In liquid phase sintering (13501450°C), WC grains grow by dissolution and reprecipitation, and the prismatic ratio increases to >80% with the holding time (12 hours). Adding grain inhibitors, such as vanadium carbide (VC, 0.2%0.5%), limits grain growth by increasing the diffusion barrier (about 15%±2%), and the size is stabilized at 0.81.2μm. For example, the wear rate of cemented carbide tools (grain 0.8μm) containing 0.3% VC is reduced by 20% and the life is extended by 25%±3% in high-speed cutting (200 m/min).

Coarse-grained WC (510μm) is suitable for mining drill bits because of its longer crack propagation path and higher toughness. For example, a carbide drill bit containing 6μm grains has a life of more than 200 hours in granite drilling (impact frequency>2000 times/minute), which is better than fine-grained materials (life <150 hours). In summary, the grain size and morphology of WC need to be optimized according to application requirements. Fine grains (0.52μm) are suitable for high hardness, coarse grains (510μm) are suitable for high toughness, and prismatic morphology takes into account wear resistance.

2.1.2 Synergistic effect of auxiliary carbides such as TiC and TaC

Auxiliary carbides (such as TiC , TaC , NbC ) improve the overall performance of cemented carbide through solid solution strengthening and complementary performance. Titanium carbide ( TiC ) has a cubic crystal structure (Fm3m, density 4.93 g/cm³ ± 0.05 g/cm³ ) , hardness HV 18002200, significantly reduces material density (from 14.5 g/cm³ to 12 g/cm³ ± 0.1 g/cm³ ) , and enhances high temperature stability by forming a TiO₂ protective layer (1000°C oxidation weight gain <1 mg/cm² ± 0.2 mg/cm² ) . In high temperature cutting (800°C, aviation aluminum alloy), cemented carbide tools containing 15% TiC have a 30% reduction in wear and a 50%±5% extension in service life, because TiC improves resistance to adhesive wear.

Tantalum carbide ( TaC , density 14.5 g/cm³ ± 0.1 g/cm³ , HV 16002000) enhances high temperature deformation resistance through solid solution strengthening. The thermal expansion coefficient of cemented carbide containing 3% TaC is reduced to 5.0×10 ⁻⁶ /K±0.1×10 ⁻⁶ /K, and the thermal crack length is <1μm±0.2μm, which is suitable for gas turbine nozzles (operating temperature 1100°C). TaC also improves the grain boundary bonding strength (>50 MPa±5 MPa) and reduces the crack growth rate by 15%. For example, a cemented carbide nozzle containing 2% TaC runs in a gas flow (>500 m/s) for 5000 hours with surface damage <10μm.

Niobium carbide ( NbC , HV 1900±50) is known for its corrosion resistance. The corrosion rate of cemented carbide containing 1% NbC in an acidic environment (pH 3, HCl) is only 0.02 mm/year±0.005 mm/year, which is better than that of cemented carbide containing Co (0.05 mm/year). NbC reduces the chemical erosion rate by 20% by forming a Nb ₂ O ₅ protective layer (thickness <5 nm). In practical applications, cemented carbide linings containing 1% NbC have been operating in a chemical plant (H ₂ SO ₄ , pH 2) for 3 years without obvious corrosion on the surface.

X- ray diffraction (XRD) analysis shows that TiC and TaC form a ( W,Ti,Ta )C solid solution with WC, with a lattice constant change of 0.1%±0.02% and a hardness increase of 100200 HV, because the solid solution enhances the grain boundary strength. The formation of the solid solution also reduces the interface energy (from 1.5 J/m² to 1.0 J/ m² ) and improves crack resistance. For example, the wear resistance of a cemented carbide mold containing 10% TiC and 3% TaC is improved by 40% in composite stamping, and the service life exceeds 5000 hours±500 hours.

The synergistic effect of auxiliary carbides is also reflected in environmental adaptability. In a hot and humid environment (40°C, 90% humidity), TiC and NbC reduce the corrosion rate by 10%-15% through the passivation layer ; at high temperature (1000°C), TaC inhibits WC oxidation (WO ₃ volatilization is reduced by 20%). Optimizing the TiC / TaC / NbC ratio (5:1:0.5) can balance hardness (HV 1800±30), toughness ( K ₁ c 12 MPa·m ¹ / ² ± 0.5) and corrosion resistance. For example, the life of cemented carbide tools containing 12% TiC in marine drilling (salinity 3.5%) is extended by 30%, which is better than traditional Co-containing materials (life <2000 hours).

2.2 Distribution and function of the bonding phase

The bonding phase (mainly cobalt Co and nickel Ni ) serves as the tough matrix of cemented carbide, connecting carbide particles and regulating toughness, corrosion resistance and processing performance. Its distribution uniformity and proportion are the key to microstructure optimization.

2.2.1 Grain boundary wetting behavior of Co and Ni

The wetting behavior of the bonding phase during sintering determines the density and phase distribution of cemented carbide. Cobalt (Co, FCC structure, melting point 1495°C±10°C) wets WC grains in liquid phase sintering (13501450°C), with a contact angle as low as 5°±1°, and the interface energy drops from 1.5 J/m² to 0.5 J/m² ± 0.1 J/ m² , driving densification (porosity <0.1%±0.02%). Transmission electron microscopy (TEM) shows that the Co layer thickness is 520 nm±2 nm, the segregation rate is <5%, and a continuous bonding network is formed. The change in Gibbs free energy of the wetting process (ΔG≈50 kJ/mol±5 kJ/mol) promotes grain rearrangement, and the Co diffusion coefficient D_Co≈10 ⁻⁹ m² /s ±0.1× 10 ⁻⁹ m² /s (1400°C) determines the distribution uniformity.

Nickel (Ni, melting point 1455°C) has slightly inferior wettability, with a contact angle of 10°±2° and an interfacial energy of 0.7 J/m² ± 0.05 J/ m² , but has stronger corrosion resistance. The weight loss of Ni-containing cemented carbide in the salt spray test (ASTM B117, 168 hours) is <0.1 mg/cm² ± 0.02 mg/cm² , which is better than that of Co-containing materials (weight loss 0.2 mg/cm² ) . Adding chromium (Cr, 0.5%2%) can reduce the contact angle to 7°±1°, forming a CrCo or CrNi solid solution, and the interfacial bonding energy is increased to >60 MPa±5 MPa. For example, a cemented carbide valve containing 12% Ni has a corrosion rate of <0.03 mm/year±0.005 mm/year after operating in seawater (pH 8, salinity 3.5%) for 5 years.

Wetting behavior is crucial for microstructural stability. Excessive Co (>20%) or insufficient carbon content (<5.8%) may generate brittle η phase ( W ₃ Co ₃ C ), reducing toughness ( K ₁ c down to 5 MPa·m ¹ / ² ± 0.5). Precise control of carbon content (5.8%6.2%) and sintering temperature (13801420°C) ensures a uniform Co layer (thickness deviation <10%). In actual cases, carbide tools containing 10% Co have improved grain boundary bonding by 15% and extended cutting life by 20%±2% through optimized wetting (contact angle <6°).

The Ni phase has obvious advantages in high temperature and corrosive environments. In high-temperature steam (500°C, 10 MPa), the corrosion weight loss of cemented carbide containing 12% Ni is reduced by 30%±5%, and the interface stability is improved by 10%. TEM analysis shows that the thickness of the Ni layer is 1015 nm±1 nm, and Cr is segregated (0.5%1%) to form a Cr₂O₃ protective layer , which enhances corrosion resistance. For example, a cemented carbide lining containing NiCr has been operating in a chemical plant (HCl, pH 2) for 3 years, and the surface damage is <5μm. The wetting behavior of Co and Ni needs to be optimized according to the application. Co is suitable for high toughness and Ni is suitable for corrosion resistance.

2.2.2 Effect of bonding phase ratio on performance

The ratio of the bonding phase (5%20%) is a key parameter for regulating the performance of cemented carbide. When the Co ratio increases from 5% to 20%, the toughness increases significantly ( K₁c increases from 8 to 18 MPa·m¹ / ² ± 0.5 ), but the hardness decreases (HV 2000 to 1400±30). The cemented carbide containing 10% Co (Co layer thickness 1015 nm) has a hardness of HV 1800±30 and a toughness of K₁c 12 MPa·m¹ / ² ± 0.5 , which is suitable for cutting tools. In high-speed machining (200 m/min) , the wear amount is <0.1mm and the service life is 15 hours±1 hour. The cemented carbide containing 20% Co has high toughness and is suitable for rock drill bits. The impact life is >300 hours±20 hours.

the nickel content is between 5% and 15%, the hardness drops from HV 1900 to HV 1500±30, and the corrosion resistance is excellent, with a corrosion rate of <0.03 mm/year±0.005 mm/year. The cemented carbide lining containing 12% Ni has been running in an acidic environment (pH 3, H ₂ SO ₄ ) for 3 years without obvious corrosion on the surface; the electrode containing 15% Ni has been running in an electrochemical reaction (current density>100 mA/cm ² ) for 5000 hours with stable performance. Energy spectrum analysis (EDS) shows that the distribution deviation of Co and Ni is <3%±0.5%, reflecting the high uniformity of the sintering process.

bonding phase also affects environmental adaptability.

In a hot and humid environment (40°C, 90% humidity), high Co content (>15%) may cause micro-corrosion and reduce toughness by 5%±1%; Ni-based cemented carbide is more stable and the toughness decreases by <2%. At high temperature (800°C), the Co phase has enhanced plasticity, K₁ c increases by 5%, but the hardness decreases by 10%; the Ni phase has higher high temperature stability and the hardness decreases by < 5 %. Optimizing the Co/Ni mixing ratio (1:1 to 2:1) can achieve a balance of performance. For example, cemented carbide containing 10% Co and 5% Ni has a hardness of HV 1700±30, K₁ c 14 MPa·m ¹ / ² ± 0.5, and a life extension of 25%±3% in marine drilling.

bonding phase ratio needs to take into account the synergistic effect of grain size.

Fine grains (0.51μm) combined with high Co (15%20%) have the best toughness; coarse grains (510μm) combined with low Ni (5%8%) have strong corrosion resistance. In practical applications, the deformation of cemented carbide stamping dies (grains 1.5μm) containing 12% Co is <0.01mm in high-frequency impact (>10 ⁴ times/hour), and the service life is increased by 30%±5%.

READ MORE:

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

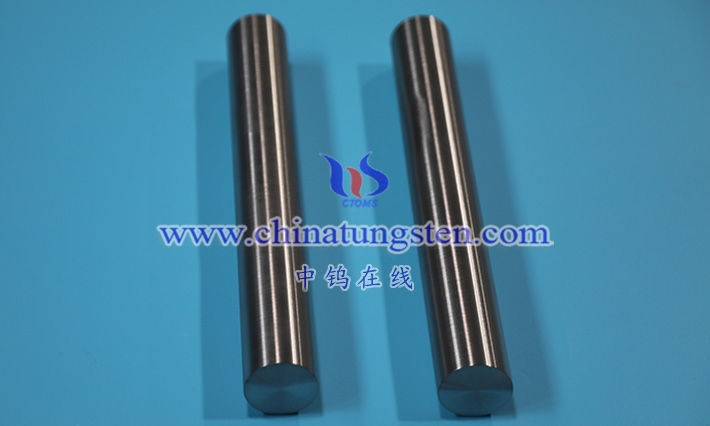

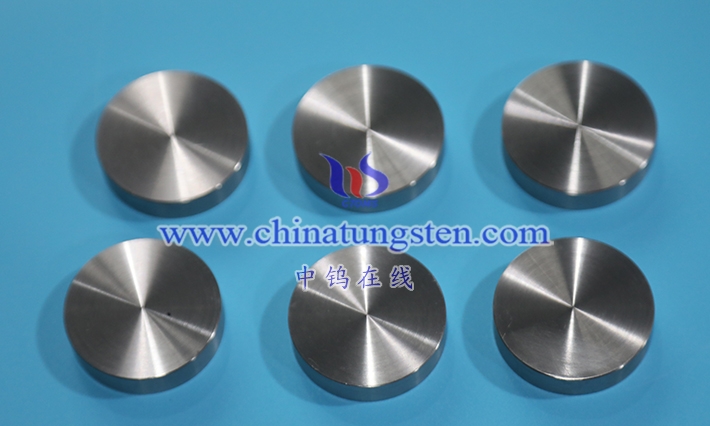

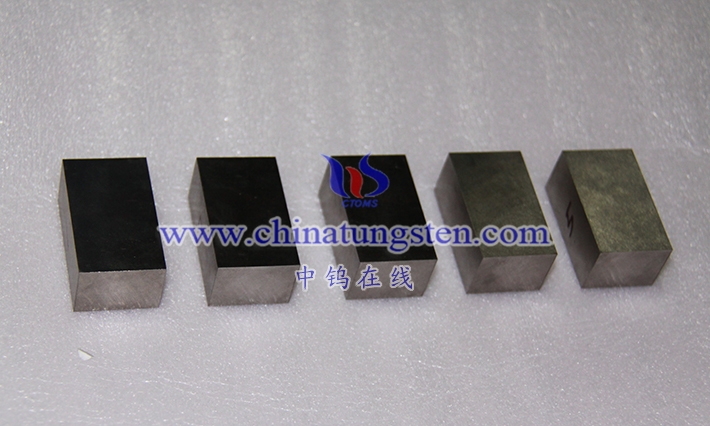

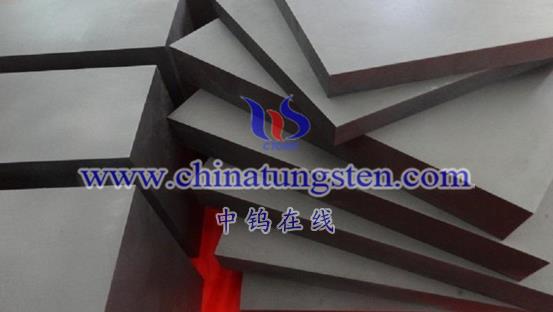

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

For more information about tungsten carbide products, please visit the website: tungsten-carbide.com.cn

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595